GF Machining Solutions LLC

560 Bond Street

Lincolnshire, IL 60069 US

800-282-1336 | 847-913-5300

info@gfms.com

gfms.com/us

IS THIS YOUR COMPANY?

Video Gallery

GF Machining Solutions Success Packs - Tailored service solutions for every need

Discover our Success Packs tailored to provide continuous support for your machines throughout their entire lifecycle, ensuring ...

High Volume Micro Sized Components – ML-5 – Nanotech Precision

Check out our interview with @nanotechprecision Discover how our partnership, associated with our cutting-edge femtosecond ...

Puzzle mold technology: the key to superior tires

Discover our EDM and Milling technologies to produce puzzle molds for tire production. Learn how these cutting-edge production ...

Tire mold engraving: direct milling for high-performance tires

Explore how direct engraving is revolutionizing tire mold manufacturing! In this video, we dive into the Milling techniques used for ...

As Seen On MoldMaking Technology

GF Machining Solutions LLC Supplies the Following Products

- Additive Manufacturing Machines for metal parts

- Additive Manufacturing Machines—Powder Bed Fusion

- DI Equipment

- EDM Services

- Five-Axis Machining Centers

- High-Speed Machining Centers

- Horizontal Machining Centers

- Milling Machines

- NC Simulation and Verification Software

- Pallet Changers

- Robots

- Sinker EDM

- Small Hole EDM, or "Hole Popper"

- Texturing Services

- Toolchangers

- Vertical Machining Centers

- Wire EDM

- Wires

Editorial, News, and Products

-

MMT's Most Popular Maintenance Reads of 2024

Peruse this past year’s top maintenance content, including topics like inspection/measurement, maintenance and repair and surface treatment.

-

2024 Moldmaking Insights: A Year in Review Part 2

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

-

Collaborative Engineering Drives Quality Mold Solutions

Advanced engineering and tooling teams collaborate to train, design, develop and deliver high-quality, cost-effective molds efficiently, ensuring perfect parts and faster launches.

-

Machining Solution Enables Growth for Production Needs

GF Machining Solutions LLC highlights its Mill P 800 U S full five-axis milling machine for automation integration. According to the company, the machine enables growth as production needs increase.

-

Target Innovation in Your Mold Shop

In this most recent roundup, MMT continues to present a variety of innovative and proven technologies, services and resources to target the ever-evolving moldmaking industry.

-

Ultra-Fast Femtosecond Laser Texturing Helps Produce EV Lighting Lens Molds

Edge-lighting lens patterns present moldmaking challenges that ultra-fast femtosecond laser texturing technology can overcome.

-

From Design to First Shot: Technologies to Improve the Mold

In this most recent roundup, MMT has curated a variety of new or proven technologies that target the moldmaking industry that have been shared on the website this month.

-

Products to Advance Your Mold Shop

This compilation of digital-only new/proven product content explores each category under MMT’s Engineer, Build, Maintain and Manage topics.

-

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

-

Digital Platform Enables Remote Machine Troubleshooting

GF Machining Solutions’ My rConnect provides a virtual link between a machine and the company’s service and support team, giving live and historical data without the need to travel to a customer’s shop.

-

Discover Metalworking Technologies Targeted to Mold Shops

What EDM, automation and machining technologies are currently available to the mold manufacturing industry? MMT has compiled a list of some of the latest.

-

In-House Surface Treatment Services for Molds, Embossing Rolls

As Mold Surface Textures celebrates 20 years in industry, the company highlights various services it offers for texturing, repair, polishing and more.

-

High-Efficiency Milling Excels in Specialized Parts Production

GF Machining Solutions Mikron Mill E 500 U offers moldmakers a sturdy, reliable five-axis machine with integrated automation opportunities.

-

Automation System Loads up Expandability, Scalability and Precision for Moldmakers

The expandable, scalable, open architecture of the System 3R Transformer system by GF Machining Solutions permits integration of various technologies to optimize mold machining operations and meet any facility’s requirements.

-

Design Strategy Tackles Big and Small Complexity Challenges for Southeastern Mold Builder

Delta Mold Inc.’s core values, engineering expertise, five-axis machines and molding capabilities help the team turn a proposal into a manufactured mold or part with custom design, finishing and assembly.

-

Technology and Sourcing Guide 2023: Additive Manufacturing

3D printing, or additive manufacturing, simplifies the moldmaking process by making mold inserts, mold components, end-use parts and ancillary equipment. Access this exclusive, online-only content, including a suppliers list, AM products and more.

-

Tech Roundup: Making Sure Your Moldmaking Needs Are Met

This month’s roundup features products, processes and services involved with additive manufacturing, maintenance and repair, mold components and more. To learn more about the products, read on.

-

Mold Builder Meets Increased Domestic Demand With Automated Cells

Burteck LLC experienced significant demand increases due to reshoring and invested in automated machining cells to step up its production output quickly and avoid losing business.

-

High-Precision VMC With Unrestricted Five-Axis Machining

The Mikron Mill S 200 U is GF Machining’s vertical high-speed machining center well suited for tool and moldmaking and exact part production.

-

GF Machining Solutions Relocates Parts Warehouse

The new facility near Indianapolis, Indiana, uses predictive intelligence to ensure availability as well as quick shipment of critical components.

-

Cross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

-

GF Divisions Present the Grand Opening of Mexico Facility

GF Piping Systems and GF Machining Solutions will be hosting the grand opening of their Apodaca, Mexico, facility on May 3, 2023. Tour the facility and learn more about the companies’ full solution capabilities.

-

Developments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

-

MoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

-

Taking the Pulse of IMTS 2022: Relationships, Next Generation and Machining

Trends and takeaways from IMTS 2022, one of North America’s longest and largest running manufacturing trade shows.

-

Wire EDM Function Eliminates Wire Breakage, Reduces Consumption

GF Machining Solutions’ new iWire function automatically identifies and adapts wire speed to changing erosion height conditions during the wire EDM process.

-

Wire EDM Machine Enhanced With High Precision, Intelligent Interface, Service Support

GF Machining Solutions spotlights the new CUT X 500 and CUT P 350 Pro wire-cutting EDM machines with heightened accuracy, precision and productivity at IMTS beside tooling, automation and software partner, System 3R.

-

Wet-Machining Graphite for Moldmakers

GR3, developed between GF Machining Solutions, Fraisa and Blaser Swisslube supports the entire machining process in one setup, optimizing cycle times, lowering tooling costs and other benefits.

-

GF Machining Solutions Appoints Medical Business Manager

GF Machining Solutions’ new Medical Center of Competency opens later this year in Lincolnshire, Illinois. It will be led by newly appointed Medical Business Development Manager Donn Wuestenberg.

-

GF Machining Solutions Announces New President of North America

Chris Jones’ more than 25 years of experience in the manufacturing industry will be pivoted toward solidifying the company’s machining solutions, as well as services and support.

-

Wire EDM Supports Intuitive, Highly Productive Operations

The GF Machining Solutions CUT P 550 Pro optimizes production for electronics, automotive, medical and mold and die manufacturers with automation options for lights-out.

-

2021 Leadtime Leader Award Winner: Westminster Tool—Perseverance with a Plan

Westminster Tool’s latest commitment to the plan—investment in new technologies, processes and capabilities, workforce development/training and sales & marketing—helped them edge out this year’s competition.

-

The Lean Dream Team: How to Achieve High-Cavitation, Critical Dimension Molds

Incorporating multiple automation technologies enables Industrial Molds to produce and repair highly complex, precision molds with a very lean team.

-

High-Precision Vertical Milling Machine for Part Processing Reliability

Launch of GF Machining Solutions’ MILL P 500 three-axis vertical milling machine offers functions for high precision, reliability, productivity and flexibility.

-

GF Machining Solutions Demonstrates AM Production, EDM Cut-Off Solutions at AMUGexpo 2020

At the 2020 AMUGexpo, exhibitor and platinum sponsor GF Machining Solutions will demonstrate its high-throughput DMP Flex 350 metal 3D printer and its AgieCharmilles Cut AM 500 horizontal wire EDM March 22-26 at the Hilton Chicago.

-

Spark Track Prevents Wire Breakage for Stable EDM Processes

GF Machining Solutions offers Spark Track technology for wire-cutting EDM.

-

EDM Speeds Up Additive Part Separation, Preserves Part Integrity

GF Machining Solutions announces the AgieCharmilles Cut AM 500, a horizontal wire EDM designed to complement metal additive manufacturing.

-

GF Machining Solutions Announces Director of Expanded Sales Department

GF Machining Solutions has announced that Peter Eigenmann has been promoted to the position of director of sales and marketing, effective October 7, 2019.

-

Accu-Die & Mold Excels in Die Cast Tooling with a Focus on Service, Engineering, and Precision Manufacturing

Accu-Die’s highly trained workforce, well-equipped shop are key to meeting the challenging demands of die-cast mold production.

-

Noteworthy News: Growth Spurts

From new facilities dedicated to automation, training and distribution to new hires eager to tackle building relationships through providing excellent customer service, the industry innovators below are growing all across the United States, Canada and Mexico.

-

GF Divisions Mexico Facility Broadens Sales and Service Support

The opening of a new GF Machining Solutions and GF Piping Systems joint headquarters in Nuevo Leon will enhance their direct sales and service support to customers in Mexico.

-

Die-Sinking EDM Optimizes Micromachining Processes

GF Machining Solutions showcases the AgieCharmilles Form X 400 die-sinking EDM solution.

-

GF Divisions Expand in Canada

GF Machining Solutions and GF Piping Systems will open a new joint headquarters to further strengthen direct sales and service support for Canadian manufacturers.

-

Tech Trends: Maximize Moldmaking Processes

Check out these latest products from Unisig, GF Machining Solutions, Mitutoyo America Corporation, CGS North America and Volume Graphics that can help you maximize your moldmaking processes!

-

The Advantages of Digital Laser Technology for Mold Texturing

Understanding the nuances and benefits of laser ablation and when to use it.

-

Noteworthy News: Helping Hands

As we hear so often in moldmaking, building relationships is one of the keys to a business’s success. So, here’s a look at some recent new releases detailing partnerships within the industry!

-

Products Unlock Full Potential of Machine Technologies

GF Machining Solutions will showcase its predictive manufacturing technology for Industry 4.0, as well as other offerings, at EMO Hannover 2019.

-

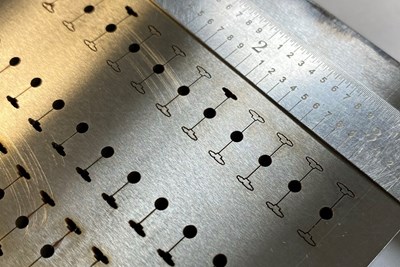

Shorten Cycle Times with Automatic Slug Removal

Automatic EDM slug management systems yield unmanned, lights-out operations, shorten cycle times and allow roughing and finishing operations with zero operator intervention.

-

GF Machining Solutions Announces Leadership Changes

As part of the company’s ongoing commitment to quality, innovation and long-term growth, GF Machining Solutions recently announced two key leadership changes, effective September 1, 2019.

-

Tech Trends: EMO Hannover 2019 Sneak Peek

EMO Hannover is a key showcase for innovations and an essential driver of global production technology, so here’s a sneak peek at the types of products you’ll see from exhibitors at this year’s event, September 16-21.

-

Advanced Technology Solutions Take Processes to Next Productivity Level

GF Machining Solutions will highlight its range of Industry 4.0-enabling technologies at EMO Hannover 2019.

-

Manufacturing Innovations Showcased at GF Solutions Days 2019

At its 2019 GF Solutions Days event, held in Lincolnshire and Chicago, Illinois, on June 27-28, GF Machining Solutions demonstrated its wide range of advanced manufacturing technology to more than 250 visitors.

-

GF Machining Solutions Demos Additive Manufacturing Flexibility at Solutions Days

The DMP Flex 350 and new EDM technology for AM promises more efficient, clean and repeatable production of dense, pure metal parts.

-

2019 Leadtime Leader Award Winner: X-Cell Tool and Mold Inc.–The Continuous Drive for Perfection

Continued investment in new technologies and automation has enabled this moldmaker to maintain shorter lead times no matter how large or complex the mold build.

-

Scratching the Surface of What Femtosecond Lasers Can Do

Providence Texture uses laser ablation with five-axis CNC lasers specifically designed for mold and part surface texturing, engraving, machining, and marking. Today the shop believes is it still only scratching the surface of its femtosecond laser technology capabilities.

-

Femtosecond Lasers Improve Mold Texturing and Micromachining

Newer femtosecond laser machine option solves common working distance challenge for micromachining and mold texturing.

-

New, five-Axis Laser Texturing System Offers Speed, Accuracy and More Geometric Options

Attendees at GF Machining Solutions’ unveiling of Laser S series say they are excited, impressed with speed and accuracy of mold texturing system.

-

Next-Generation All-In-One, Digital Laser Texturing System Unveiled

GF Machining Solutions introduces the new, fully-digital, multiprocess Laser S series for texturing molds.

-

The Journey to Finding America’s Greatest Champion

Terry Iverson shares his journey to self-publishing his book, Finding America’s Greatest Champion, in an effort to educate those outside of manufacturing about great opportunities in manufacturing, changing perceptions along the way.

-

Modular Automation System Integrates with Wide Variety of Technologies

The System 3R Transformer modular automation system from GF Machining Solutions integrates with a wide variety of technologies.

-

Experience, Knowledge Base, and Creativity Give Tri-Par An Edge in Molds for High-Flow Material Parts

Expertise in building molds for parts made from highly-engineered materials and automation for molding gives Tri-Par Die and Mold Corp. key mechanisms for growth.

-

GF Machining Solutions Reaches Milestone

GF Machining Solutions celebrates activating the 1,000th connection of its rConnect digital services platform.

-

Fraunhofer, Ericsson and GF Machining Join Forces

Fraunhofer, Ericsson and GF Machining Solutions have combined expertise in telecommunications and manufacturing to create a real-time process monitoring solution based on 5G technology to communicate with sensors and machines to reduce errors in jet engines milling production.

-

GF Machining Demonstrated the Future of Manufacturing at IMTS

Visitors at the GF Machining Solutions’ IMTS booth saw demonstrations of a range of technologies and machining that address manufacturing challenges.

-

Collaboration, Flexibility, Speed and More at IMTS 2018

Attendees walked the miles of aisles to find that IMTS 2018 delivered it all and so much more.

-

IMTS 2018: Process,Technology and Service Advancements

Advancements in automation and digital manufacturing took center stage during IMTS last week, but developments in additive manufacturing, cutter technology, machining solutions, simulation software, EDM, laser technology and customer service were other hot items.

-

2018 Technology Review and Sourcing Guide: Additive Manufacturing

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including additive manufacturing.

-

Hexagon Partners with GF Machining and FANUC America

Hexagon hosts an open house event alongside GF Machining and FANUC America in Huntersville, North Carolina.

-

2018 Technology Review and Sourcing Guide: Machining

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including machining.

-

EDM Machine Size is Paramount

The constant need for larger, more efficient machining capability pushed Extreme Wire EDM Services to approach GF Machining for a larger wire EDM solution.

-

2018 Technology Review and Sourcing Guide: EDM

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including EDM.

-

SPE Mold Technologies Division Honors Charles Klingler

The Mold Technologies Division of the Society of Plastics Engineers (SPE) honored Charles Klingler of Janler Corp. at Amerimold 2018.

-

2018 Leadtime Leader Award Winner: Maximum Mold Group

Strategic acquisitions and diversified capabilities combined with a can-do, inclusive culture take this mold manufacturer to new heights.

-

High-Speed Mills Increase Output of Complex Graphite Electrodes

Tri-Gemini LLC has added graphite milling capability with the purchase of two additional GF+ Mikron 500 high-speed mills.

-

GF Machining Solutions Hosts Grand Opening of Aerospace Center

GF Machining announces grand opening of North Carolina Aerospace and Energy Center of Competence.

-

Laser Machine Designed for Texturing of Precision Parts

GF Machining Solutions has a AgieCharmilles Laser P 400 U machine on display at NPE2018 in booth S37079.

-

GF Machining Solutions Announces New Sales and Marketing Team Members

The company recently hired Dante Payva, Sammy Shabib, Heather Natal and Jon Carlson.

-

Stand-Alone Additive Manufacturing Is a Thing of the Past

Additive manufacturing (AM) is no longer considered a stand-alone technology but is increasingly being integrated in existing manufacturing processes.

-

Technology Tuesday: EDM Success

Cruise through this week’s Technology Tuesday slideshow to see EDM units that shops across the country have used to increase capacity and leverage greater efficiency in their processes.

-

Compact EDM Machine Has Varied Features for Accuracy and Ease of Use

GF Machining Solutions’ new compact Form E 350 machine has a generator for quality surface finishes and precision applications in any conductive material.

-

Realizing EDM's Full Potential with Automation

EMO Hannover 2017 was a showcase for EDM developments, automation solutions and software for data-driven manufacturing.

-

Technology Tuesday: Equipment of the Leadtime Leaders

Cruise through this slideshow to see what technology Leadtime Leaders use to make significant contributions to their fields.

-

Extra Large Wire EDM Capacity Places Shop on Path for Growth

The constant need for larger, more efficient machining capability pushed Extreme Wire EDM Services to approach GF Machining for a larger wire EDM solution.

-

The Danger Zone

Spindle crashes can have costly consequences. Collision protection systems can help minimize the damage.

-

Manufacturing Day is an Opportunity for our Industry

How are you celebrating our national day, Manufacturing Day, this year? October 7 marks the fifth year since Manufacturing Day was established in the US, Canada and Mexico, and the mold manufacturing industry should embrace the opportunity to spread the message that moldmaking is cool!

-

Kids, Machines and Manufacturing Days

Students from a dozen Chicago area high schools toured GF Machining Solutions’ front office, warehouse and demonstration center during its Manufacturing Days event.

-

Another Look at EDM Generator Technology

Advancements in fully digital sinker EDM generators offer benefits in mold maintenance, process efficiency and electrode wear.

-

New Era, Same Winning Formula

This company succeeds by staying up-to-date on technology and being willing to do a bit extra in the name of customer service.

-

Slideshow: EMO 2015

Here are some highlights from this year's event.

-

“Smart” Technology Boosts EDM Efficiency, Quality

Three EDM innovations showcased at GF Machining Solutions’ recent “Solutions Days” open house have one thing in common: they automatically adjust generator settings according cutting conditions, operator preference or both.

-

2015 Leadtime Leader Awards Honorable Mention: Dynamic Tool & Design - Committing to a Scientific Process

This shop’s recent strides in mold qualification mirror an ongoing transition to a more systematic approach to mold manufacturing. Meanwhile, a culture of ownership ensures a full buy-in from veteran employees as well as fresh talent attracted through extensive workforce development efforts.

-

Flexibility, Low Overhead Seed Sustainable Success

Robotics, cross-training and efficient use of available floorspace help this shop adapt to the ebb and flow of business.

-

Laser Texturing Proves Automotive Potential

A cosmetic interior tooling application in North America could spell a brighter future for a process that promises savings throughout the supply chain.

-

Striking a Balance with Global Production

Due diligence and the right business model gives Burteck the flexibility to reap the rewards of overseas mold manufacturing while limiting potential drawbacks.

-

Minding the Business

This toolmaker and low-volume injection molder’s diversification shows that business savvy can be just as critical to success as an efficient manufacturing process.

-

All According to Plan

This moldmaker influences its own destiny by staying true to itself, knowing exactly where it wants to go, and ensuring everyone in the organization understands how to get there.

-

Industrial Size Investing

Our 2012 Leadtime Leader Winner has made some big investments in new machinery and facility renovations to match its current business level and continued growth, as well as to attack its production bottlenecks.

-

IMTS: Automate Your Way out of the Skilled Labor Shortage

GF Machining Solutions is on a mission this IMTS to help industry overcome the skilled labor shortage and stay competitive at the same time. Their solution is automation.

-

The Advantage of a Trunnion

For this moldmaker, a trunnion-style five-axis machine offered certain advantages over its previous, swivel-head-style models.

-

Taking the Next Step Toward Five-Axis Efficiencies

This moldmaker’s latest five-axis machining center has improved cycle times and surface finish on certain parts while freeing older machines to process other work.

-

2014 Leadtime Leader Awards Winner: Westminster Tool Inc.—Bridging the Gap without Losing Focus

A strong sense of self and a focus on people enabled this mold manufacturer to rapidly expand pre- and post-manufacturing services without getting overwhelmed by its own growth.

-

Going to Extremes with EDM Drilling

Expertise in drilling start holes helps this wire EDM shop give 110 percent on every job without breaking the bank.

-

Name Change Reflects Diverse Offering

The name GF AgieCharmilles may be best known for its EDMs, but the division of global industrial firm Georg Fischer AG has far more to offer. To reflect growth in other areas, the entity is now called GF Machining Solutions.

-

Look at Laser Ablation Lately?

We first covered laser ablation being applied in moldmaking back in 2011, but in recent months we've been hearing a lot more about it. This prompted us to reached out to industry for some insight that I thought I'd share.

-

Think Metric, Part 3

Insight from several technology suppliers—in design software, mold components, programming, machines, cutting tools and measurement equipment who have been following the metric trend—may help to make the transition a smooth one.

-

Hygienic Ice Cream Cones, Thanks to CAM Software

CAM software ensures that ice cream vendors have an added degree of hygiene by allowing for the manufacture of a product that ensures the ice cream vendor doesn’t have to touch the waffle cone.

-

Raising the Bar on Better

A look at one project to move away from traditionally customized moldmaking toward a level of complete automation that raises the bar on accuracy, repeatability and control.

-

2013 Leadtime Leader Awards: Honorable Mention Micro Mold Company, Inc.: Partnering to Push the Limits

This mold manufacturer wins the 2013 Leadtime Leader Honorable Mention title because it exceeds expectations with a team mentality—stemming from its youthful leadership working closely with skilled tradesmen—that sees customers, its sister molding company and industry associations as true partners.

-

2013 Leadtime Leader Awards: Winner Tech Mold Inc.

A three-division approach, technology innovation and a grow-your-own skilled workforce allows this mold manufacturer to balance the entire moldmaking process — ensuring continued success and landing it this year’s 2013 Leadtime Leader Award Winner title.

-

Keeping Molds Running

Technology advancements encourage moldmakers to think about surface treatment, mold maintenance and repair issues earlier in the mold build process to obtain better mold performance and life.

-

Precision Mold Shop Doubles EDM Capacity and Triples EDM Output

Janler’s business philosophy centers on “running the operation as a business, not a shop.

-

Additive and Subtractive Together

At the recent International Manufacturing Technology Show in Chicago, EOS and machine tool maker GF AgieCharmilles demonstrated additive and subtractive processes working together to produce a titanium tibial tray for knee implants.

-

Motorola RP Services: 20,000 Electrodes and Counting

Motorola has placed an increased emphasis on adding new software tools to improve its engineering and manufacturing operations. For its moldmaking business, this has meant implementation of new procedures in Cimatron-E and implementation of a Hexagon PC-DMIS solution on the shop floor.

-

EDM Efficiencies Excel

Advancements in EDM processes in terms of machining speed and surface finish improve overall accuracy, productivity and profitability.

-

Merging Manufacturing Technologies at IMTS 2012

A live demonstration of embracing both subtractive and additive manufacturing was one of the highlights for me at IMTS. Machine tool builder GF AgieCharmilles and EOS showcased an innovative start-to-finish manufacturing process chain that creates actual titanium tibial trays for surgical knee implants.

-

Automation Advancements Streamline Mold Manufacturing

Implementing new technologies across the entire shop floor improves overall accuracy, productivity and profitability.

-

Systems Approach to Micromachining and Molding Yields Accuracy

This systems approach to micromachining includes multiple cavities in the molds for the plastic injection over molding portion of the LED manufacturing process.

-

Machining Outlook: Reap the Benefits of Technology Advancements Working Together

A roundtable of machine tool suppliers reviews the advancements in machining technologies that push machining and tooling to their limits—and can kick every moldmaker’s capability up a notch.

-

Increase Profits Through Decreased EDM Electrode Wear

Recent advancements in the technology behind low-wear capability have drastically improved the machining speeds at which low-electrode-wear application settings can be applied.

-

Focus on Performance: GF AgieCharmilles hosts Technology Days 2011

With a focus on improved performance and new applications, GF AgieCharmilles Technology Days 2011 offered educational seminars and machine demonstrations to an estimated 170+ customers, technology partners, and industry press.

-

2011 Leadtime Leader Awards: Large Shop Honorable Mention

MSI Mold Builders: Redefining Mold Manufacturing with Incremental Approval Approach.

-

Seamless Process Creates the Impossible Cooling Channel

A multiple-machine moldmaking process—combining DMLS, high-speed five-axis machining and EDM— produces conformal-cooled molds in a seamless automatic process.

-

2011 Leadtime Leader Awards: Large Shop Winner

United Tool & Mold, Inc.: Charging Forward with Unique Mold Repair Niche.

-

Reinvesting in Machinery, Processes and People Adds to Bottom Line

Specializing in high precision molds with interchangeable components, RMM has supplied the industry with a wide variety of tools including, single face, stack, unscrewing, multi-material, rotary cube technologies—and considers its customers’ needs a number-one priority.

-

Laser Ablation for Surface Texturing

How moldmakers can improve the level of control exerted in surface texturing.

-

Wire EDM an d Diesinking Tool Changer

GF AgieCharmilles (Lincolnshire, IL) offers the CUT 20P wire EDM featuring a variety of new evolutions, including a new dielectric unit with three vertical Grundfos pumps for increased performance.

-

2010 Leadtime Leader Award Small Shop Winner Mold Craft, Inc.: Innovation with Automation

With an average leadtime of eight weeks, Mold Craft, Inc. (Willernie, MN)—this year’s Small Shop Leadtime Leader Award Winner—builds tight-tolerance, high-volume, multi-cavity and multi-mold projects that produce small, intricate, precision plastic parts.

-

The Dielectric Decision: Water or Oil

The emergence of today’s technologically advanced oil-based wire EDMs is an opportunity for the average U.S. mold builder to set himself apart from the competition.

-

Automation Innovations

The use of automation continues to rise as mold manufacturers respond to industry demand of constantly shrinking leadtimes. Manufacturers and suppliers have taken action with better, faster equipment and processes.

-

Machining Madness: Advances in HSM

The industry’s demand for higher quality, faster turnaround times and lower prices in the last decade has resulted in dramatic improvements in high speed machining as well as controls and spindles.

-

Automation, Innovation Chart EDM’s Course

Advances in EDM technology—including increased automation and combining machining processes to get the job done as efficiently as possible—help EDM stay afloat and keep moldmakers successful.

-

Intelligent Machining Software to Increase Surface Finish and Productivity in Mold Mfg

Progress in the realm of software offers moldmakers the opportunity to maximize the potential of their machining processes when it comes to maintaining extremely high surface finishes.

-

Aerospace Molds Need Proper Mix Of Application and Technology

This moldmaker flies high with a combination of specialized processes and modern technologies required for the extremely tight tolerances and exotic material concerns in the aerospace industry.

-

Achieve More with Twin Wire EDM Technology

As wire costs continue to increase, twin wire will be recognized as a strong tool for fine tuning wire EDM performance and reducing cost.

-

Harnessing EDM Technology for Micromoldmaking

For moldmakers considering making their foray into micromoldmaking, a solid understanding of the benefits of new EDM technologies is necessary to make the transition as smooth as possible.

-

New PET Bottle Standard May Boost Business for Moldmakers

A rule to lightweight preform necks and closures could require more than 1,000 new molds.

-

Injection Mold, Inc.: RP Niche Yields Success

This moldmaker plays it close to the vest with strategies and practices, but one can learn from its serious investment in the latest technologies to provide quick-turn and RP tooling in record time.

-

M&M Tool and Mold, Inc.: Automation Investment Pays Off Big

Heavily relying on lights-out manufacturing coupled with a niche market in complex mold manufacture, this moldmaker lands its fourth accolade as a Leadtime Leader—three times as a winner and this year’s Leadtime Leader: Small Shop Honorable Mention.

-

Tech Tool & Mold, Inc.: Strength and Flexibility

This moldmaker garners the 2007 Leadtime Leader Award: Small Shop by being flexible with its customers, going lean, competing globally and uniting with other moldmakers.

-

Do-Rite Die & Engineering: Doing Right by Its Customers With Die Cast Dies

Learning the intricacies of die cast die building offers moldmakers an alternative to mold manufacturing and can generate more repeat business.

-

Precision Manufacturing Institute: Specialized Training

This school works hand-in-hand with suppliers and shops—relying on their expertise and input to stay on top of industry trends and help develop a tailor-made curriculum in precision machining and moldmaking.

-

Advances in Hot Runner Systems Drive Innovations in Part Engineering and Styling

Design and performance capabilities of components fabricated in state-of-the-art molds enhance the appeal of new vehicles.

-

Five-Axis Machining Is a Key Requirement for High-Precision Molds

Design and fabrication capabilities of advanced tool-cutting processes give toolmakers an edge in developing new business.

-

Molding New Moldmakers

One school—with industry’s help—is a model for our future moldmakers’ education.

-

Automation and Moldmaking: Mold Production in Action

Moldmakers are starting to change the way they think and incorporate automation into all aspects of their operation—combining a multitude of processes in a single cell for optimal productivity.

-

Process Management Leads to Easier Automation

Before you move your shop into full blown automation, integrate a pallet system and process management software.

-

Moldmakers Counter Offshore Sourcing with State-of-the-Art Capabilities

Advanced engineering and mold building techniques give North American toolmakers entrée to emerging electronics applications.

-

Tech Tool & Mold, Inc.: Staying Focused

This moldmaker’s firm belief in continuous education for its employees combined with advanced training and cutting-edge technologies increases total delivered value of its products.

-

Concept Mold & Die: A Bright Idea

This moldmaker empowers its employees and wisely invests in technology to ensure its survival for the long haul.

-

Prodigy Mold & Tool: Taking Things One Step at a Time

Drive and determination results in a decade of success for this small moldmaker specializing in multi-cavity precision molds.

-

Mold Builders Carve Lean Niche

Commodity-oriented consumer manufacturing left North America, but mold industry survivors are finding strong growth in technical market sectors.

-

Molding Success Through Automation

HSM technology helps U.S. moldmaker maintain world-class productivity and business growth.

-

Medical: The Right Rx for American Tool Builders

When technology, quality and speed step to the fore in the medical world, so does the North American mold and die industry with some innovative products and processes.

-

Global Outlook for Mold Manufacturing

Tool and die/precision machining industry trends are amazingly uniform worldwide. Business is tough almost everywhere, but getting better.

-

Smart Machining: A New Development in High-Speed Machining

Improved process reliability, optimized machining performance and reliable unmanned operation are the results of smart machining implementation.

-

MSI Mold Builders: Moldmaking Measured and Defined

A combination of lean strategies coupled with niche moldmaking garners this shop the MoldMaking Technology 2006 Leadtime Leader Honorable Mention: Large Shop.

-

Forty to 200 Percent ROI on Training

Strategies for attacking the lack of ongoing training dilemma that directly impacts our shops.

-

It’s Gut-Check Time for Tool Builders

It’s time to adapt or die as business evolution dictates development of new business and manufacturing approaches.

-

Wear Parts and Consumables: The Keys to Maximizing Your EDM

Mold shops need to pay attention to the potential impact wear parts and consumables can have on their overall production.

-

Up Close and Personal

Getting up close and personal with the latest current and emerging technologies affecting the mold industry is the best way for mold manufacturers not only to see what is out there.

-

Taking Control of Finer Surface Finishes at Higher Speeds

An increased interest in five-axis machining—coupled with advances in controls and cutting tools—add up to finer surface finishes at higher speeds.

-

How to Implement Ultra Productive EDM

Steps to help maximize the potential of your current die sink or wire EDM system.

-

Burning Bright

EDM experts reveal that trends in increased automation combined with unattended machining result in better accuracy and surface finishes in wire and diesinking EDM applications.

-

EDM Technology Leads in the Race to the Finish Line

Mold shops should look to race shops for technologies and strategies to help reduce their mold build leadtimes.

-

How to Increase the Process Speed of Die Sinking EDM

An increase in productivity of approximately 30 percent, and up to 100 percent with pre-milled molds, is possible with new EDM technology.

-

The Race to EDM Automation

In order for moldmakers to compete with overseas forces and their huge labor cost advantages, automation is no longer an option...it is a necessity.

-

Century Die: Forging Ahead

Manufacturing blow molds has kept this moldmaker in the black for more than fifty years-and has earned them an Honorable Mention in MoldMaking Technology magazine's Leadtime Leader competition.

-

Keeping Your Mold Shop Competitive

To remain competitive in the mold manufacturing market every mold shop needs to answer three questions about its diesinker EDM.

-

HSM Equals Accuracy and Precision at Less Cost

A California moldmaker makes the most of state-of-the-art machine tool and design technology to deliver competitive advantages for a medical device customer.

-

Tips on Improving Wire EDM Productivity

By focusing on such aspects as maintenance, tooling and training, moldmakers can increase the productivity of their wire EDM significantly.

-

High-Performance Graphite Electrode Machining

Today, it is popular to talk of eliminating electrodes for hard die milling.

-

Advances in Automation for Mold and Die - High-Performance Machining and EDM

Recent developments in automation are providing benefits for the high-performance machining (HPM) of electrodes and steel mold components.