Seamless Process Creates the Impossible Cooling Channel

A multiple-machine moldmaking process—combining DMLS, high-speed five-axis machining and EDM— produces conformal-cooled molds in a seamless automatic process.

When it comes to injection and blow mold tooling, the cooler the better, and cooling channels are what keep tooling temperatures in check. Optimized cooling channels improve mold product quality, extend mold tooling life and increase the efficiency of the overall molding process.

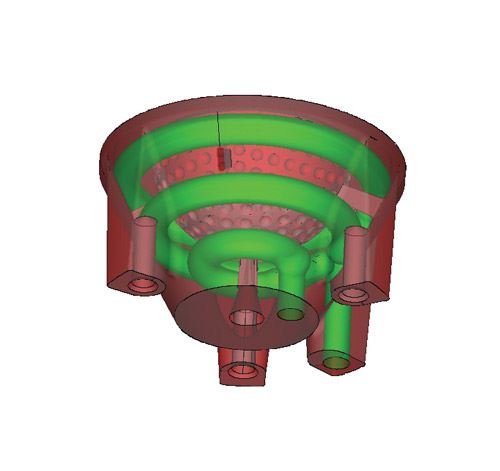

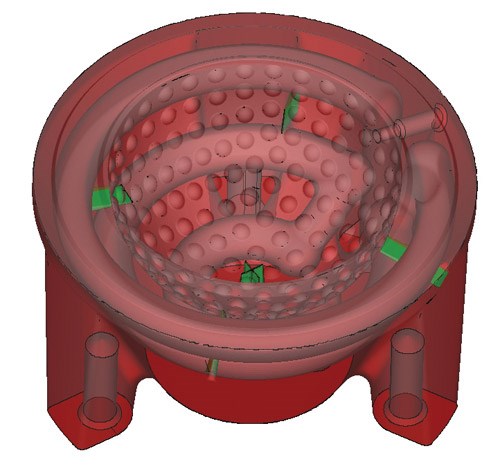

However, there are mold shapes that can make machining optimized tool cooling channels impossible. A perfect example would be the cylindrical shaped molds used to produce golf balls. Optimal cooling channels in tooling for these molds would be ones that would mirror or conform to the cylindrical shape of the mold cavity.

Conventional machining methods would come up short for producing such a cooling channel pattern—angled holes would basically be the only option. But thanks to a multiple-machine mold tooling manufacturing process that combines Direct Metal Laser Sintering (DMLS), high-speed five-axis machining, and Electrical Discharge Machining (EDM), producing conformal-cooled molds has become a practically seamless automatic process.

This manufacturing process chain is one that runs virtually unbroken from design to finished product. Machines used in the process are networked together and operate from the same 3-D CAD model data from start-to-finish, increasing accuracy and reducing set-up times. Moldmakers can basically work from a 3-D model and build a mold insert around it with perfectly-located conformed cooling channels.

Conformal-cooled molds are already well established and have enabled many high-end manufacturers to reduce (plastic) product-production cycle times by as much as 40 percent. Such DMLS-manufactured molds improve product quality and promote longer tool life, and the optimized cooling increases the efficiency of the whole molding process as well. For large-volume production, the resulting time and cost savings—as well as carbon footprint reduction—are considerable.

There are many documented success stories from moldmakers who have benefitted from DMLS to create molds, which employ conformal cooling channels. But partnered with high-speed milling and EDM within one manufacturing chain, allows DMLS to be more easily implemented, especially by those manufacturers running high-volume injection and blow molding operations.

In the multiple-machine process chain, the DMLS system creates the steel mold complete with conformal cooling channels and the fixturing needed for all successive stages of machining. This mold then moves through the secondary portion of the process chain that involves the high-speed milling machine and the EDM processes, both die-sinking and wire types.

A significant advantage of DMLS is that it produces a near-net part, in one operation, that is ready for secondary finishing. Single fixturing systems are then used for all secondary operations to reduce manual benchworking and ensure surface finishes are accurate to within 3 to 5 microns. The process minimizes scrap by eliminating many of the progressive operations involved in subtractive toolmaking processes that start with a block of raw material.

For refining the DMLS part surface finish, the mold transfers to the high-speed milling machine that cuts the mold’s parting line for a flash-free (no leakage) surface, and finish cuts other molding surface areas. Then the mold transfers—using the same fixturing as used by the high-speed mill—to a die-sinking EDM that finish cuts inside mold cavities. A wire EDM cuts off the mold fixturing, and the mold is ready for production use.

All the operations—DMLS, 5-axis high-speed milling and EDM—within the mold manufacturing process run simultaneously. And, the incorporation of pallet workholding plays a key role in helping to reduce overall process time.

For certain geometries, the DMLS machine can be equipped with dedicated clamping solutions, which ensure the future correct positioning of the built parts. By doing so, two essential goals can be achieved: the accuracy of the referencing of the parts and the effortless transfer from the high-speed milling machine to the EDMs.

Integrating DMLS with high-speed machining and EDM not only ensures that mold components accurately pass from one process to the next, but also improves the overall manufacturing integrity of producing mold components with conformal cooling channels. And as more moldmakers incorporate the use of these optimized cooling channels, the need for such integrated multiple-machine systems that provide seamless automatic processing will continue to grow.

Related Content

4 Keys to a Successful Mold-Building Operation, The Latest Mold Design Tips & More

MoldMaking Technology is off to a strong start this year with mold design tips, key considerations for running a mold-building “business,” polishing pointers for ribs and more. Check out our list of top-viewed articles from January and see what catches your eye.

Read MoreMMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreLarge Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read MoreHow to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

Read MoreRead Next

Direct Metal Laser Sintering and Tooling

The applications, benefits and limitations of direct metal laser sintering for mold manufacture.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More