Tool Steel

End Mill Delivers Maximum Cutting Volume for Steel Materials

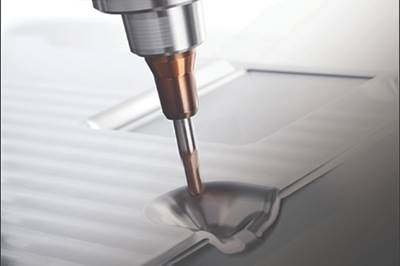

Haimer USA highlights the upcoming Panther Mill, its latest innovation in high-performance cutting tools to benefit the machining processes beginning in 2025.

Fiona Lawler

Associate Editor, MoldMaking Technology

How to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreVIDEO: Innovative Materials Boost Mold Efficiency

Advancements in metal 3D printing and stainless steel optimize mold building for diverse, high-demand industries.

Read MoreCanada Imposes 100% Tariff on Chinese EVs; 25% Surtax on Chinese Steel/Aluminum

Canada will impose a 100% tariff on Chinese-made electric vehicles (EVs), effective October 1 and a 25% surtax on Chinese steel and aluminum imports effective October 15.

Read MoreVIDEO: AM Powder Addresses Current Inefficiencies, Sustainability and Skills Gap

Steel supplier discusses high thermal conductivity metal powders that also address the skills gaps via user-friendly materials and promote sustainability via durability and higher cycle counts.

Read MoreMachine-Ready Blanks Enable Various Moldmaking Capabilities

IMTS 2024: TCI Precision Metals highlights its precision machine-ready blanks’ capabilities to assist moldmakers in saving valuable shop time.

Read MoreCoating Technology Enables Tough Mold and Die Steel Machining

Millstar, a part of Cole Tooling Systems, presents a multi-layer hybrid nanocoating for cutting tools that provide key benefits for increased efficiency in any machining operation.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Technology Review and Sourcing Guide 2024: Mold Materials

Building a high-quality mold requires the proper selection of appropriate mold materials. Tool steel, aluminum, copper and alloys are a just a few examples you can fin in this exclusive, online-only content that includes a supplier list for mold materials.

Read MoreHow to Lower Cycle Times With the Right Tool Steel

Combining excellent mechanical properties, high wear resistance and high thermal conductivity in a specialty tool steel yields cycle time reduction.

Read MoreAdvancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

Read MoreStainless Steel Grades Eliminate Complex Machining Challenges

Unlike traditional stainless steel, Swiss Steel’s Ugima-X martensitic and duplex steels feature good machinability high reproducibility.

Read MoreProject Reveals Added Benefits of New P20 Grade Steel in Machinability, Cycle Time and No Stress Relief

MoldMaking Technology's Christina Fuges talks with General Motors' Shane Appel about a project testing a new P20 steel grade's dimensional stability.

Read MoreMachine-Ready Blanks Help Mold Shops Reduce Production Time

Plate and sheet distributor TCI Precision Metals offers made-to-order square, flat and parallel blanks in a variety of material options and with added feature options.

Read MoreHeat-Resistant Tool Steels Advance Die-Casting Applications

Swiss Steel introduces its latest innovations in tool steels, showcasing significant advancements in heat resistance and durability for die-casting applications. In particular, advancements that address the extreme thermal stresses inherent in high-temperature production processes.

Fiona Lawler

Associate Editor, MoldMaking Technology

Tool Steel Alternative to S7-Based Molds

NPE2024: International Mold Steel showcases its DCMX steel as an alternative to S7, providing mold builders uniform hardness for even machinability and clean welds and other benefits.

Read MoreReliable, Efficient 3D Printer for High-Quality Tool Steel Components

The updated TruPrint 2000 underscores Trumpf’s focus on the tool and die industry, including a larger, square build plate and various features to ensure high quality and mass production.

Read MoreFeature Updates Add to Offline Robotics Programming Software

The SprutCAM X 17.0.11 release includes a comprehensive set of bug fixes and addresses issues concerning software stability, reliability and performance enhancements.

Read More3D Printing Tool Steels Reformulated for More Flexible, Less Brittle Filaments

Markforged has reformulated its H13 and D2 tool steel filaments for use with its Metal X 3D printing system.

Read MoreCutter Designed for Roughing in Face, Profile Milling Operations

The Sandvik Coromant CoroMill MR80 now caters to steel milling applications, which require the security of a round cutting edge — for instance, when face and pocket milling mold bases.

Read MoreAlro Steel Expands Metal Offerings Via Pottinger Steel Acquisition

Third company purchase this year brings carbon steel, alloys, stainless steel, aluminum and other metals under Alro Steel’s distribution capabilities.

Read MoreTool Steel Offers Advantages For Production Efficiency, Component Service Life

Swiss Steel USA’s E 40 K Superclean offers benefits for a more efficient manufacturing processes in terms of production efficiency and component service life.

Fiona Lawler

Associate Editor, MoldMaking Technology

Micro-Milled Steel Plate Cuts Mold Build Times by 10-15%

Steel 21 emphasizes its tighter tolerances, improved surface quality and speed of processing using the patented “21 Micro Milling” process.

Read MoreVIDEO: Qualifying Modified H-13 for 3D-Printed Tooling

Next Chapter Manufacturing and International Mold Steel discuss their partnership to qualify a modified H-13 for tooling applications.

Read MoreHow to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection, there are many variables that can dictate the best option for moldmaking.

Read MoreMold Materials Guide Eases Steel Selection

Newly released Materials Guide from Swiss Steel Group offers mold builders a quick and easy way to navigate the company’s steel solutions, applications.

Read MoreShaping Steel Enables More Complex, Efficient Injection Molds

AddUp’s AISI 420 stainless steel is commonly used to manufacture molds for plastic injection molding, as it has high mechanical strength and good corrosion resistance.

Read MoreQualified Tool Steel Enhances Thermal Transfer, Long Tool Life

Next Chapter Manufacturing has successfully qualified HTC-45 tool steel, an optimized version of H13, to support better thermal transfer and faster cycle times for molders and die-casters.

Read More