Spark Track Prevents Wire Breakage for Stable EDM Processes

GF Machining Solutions offers Spark Track technology for wire-cutting EDM.

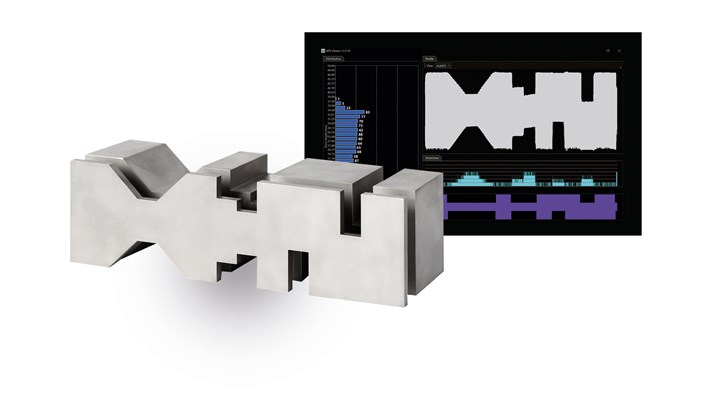

GF Machining Solutions offers Spark Track technology for wire-cutting EDM. Spark Track, powered by the company’s Intelligent Spark Protection System (ISPS) module, prevents wire breakage that occurs when cutting irregularly shaped workpiece features. With Spark Track technology and the ISPS module, wire EDM users gain secure and uninterrupted EDM processing, improved machining efficiency and ease of use for operators.

The Spark Track technology, which won the 2019 Prodex Award that honors pioneering products, harnesses modern electronics – sensor signal, speed and effectiveness – to constantly monitor the spark distribution along the EDM wire. Based on the spark data gathered, the ISPS analyzes and automatically recognizes shape changes and adapts machining parameters accordingly to prevent wire breakage during roughing. As a result, irregular shapes such as cavities, varying heights, taper surfaces and sharp corners are roughed without the need for operator intervention to set up machining conditions in advance. As a result of the highly secure EDM process enabled by Spark Track, customers can benefit from 100% automation, which in turn reduces the cost per part.

Angled part surfaces are a prime example of where Spark Track and the ISPS module bring high efficiency to the wire EDM process. Such tapered surfaces can create non-homogenous flushing conditions at a wire EDM’s upper nozzle, disrupting the machining process. The ISPS module eliminates the need for the machine operator to adjust the machining process to accommodate such difficult machining conditions since the technology analyzes the spark distribution data, automatically recognizes the shape change and adjusts the process to increase machining efficiency.

Related Content

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.