Flexibility, Low Overhead Seed Sustainable Success

Robotics, cross-training and efficient use of available floorspace help this shop adapt to the ebb and flow of business.

Ask Kent Smith about the challenges he faces in the injection mold manufacturing business, and you’ll hear a lot more about solutions and triumphs than problems and frustrations. That might be due to nothing more than an optimistic outlook, but there’s also concrete evidence that Smith has plenty to feel positive about these days. The company he founded in 1989, Diamond Tool & Engineering, added its first injection press for in-house testing and sampling less than a year ago. It also brought in a new hire with the expertise to oversee—and optimize—those operations. Shortly after, it invested in mold flow simulation software to better serve customers. Another fresh face in the engineering department is the first of a few planned personnel additions there. The company recently added a third robotic cell, and a second five-axis machining center is potentially also on the horizon.

Given the situation just a few years back, the company’s growth has been all the more rewarding, Smith says. Having laid off its second and weekend shifts, a much leaner Diamond Tool emerged from the Great Recession into an environment characterized by slower workflow punctuated by periods of intense, capacity-straining activity. Low overhead, automation and cross-training not only helped navigate that particular rough patch, but also better prepared the shop to flex with future business conditions, Smith says. Also notable is the fact that none of these steps were taken in isolation. Then, as now, the shop wasn’t afraid to learn from its peers, share its own ideas and leverage the broader moldmaking community to evaluate the success of its efforts.

A Tight Ship

The timing of the 2008 slowdown was particularly bad for Diamond Tool & Engineering. Based in Bertha, Minnesota, the company operates a second facility in Laura, Ohio, that’s dedicated to repair, engineering changes, and service and support for automotive customers. When the recession hit, those operations had just moved into a larger building. Suffice to say that the company’s overall philosophy of striving to keep fixed costs low proved its worth that year.

This same, cautious approach also informed the evolution of Diamond Tool’s headquarters facility, which handles the bulk of mold production for a diverse array of customers. From the very outset, leadership opted to prioritize investments in technology and people over facilities whenever possible, Smith says. Space is tight—at one point, the company removed part of a restroom to make room for new equipment. “We certainly don’t have the Taj Mahal for a shop,” he says.

However, as long as workflow isn’t impeded, using space efficiently can be a great help in adapting to the ebb and flow of business, Smith says. “You cannot go backwards on fixed costs,” he explains. “Once you’ve accumulated a certain amount of overhead, your hands are tied. For us, this approach has helped reduce the need to lay off key employees when we’ve had to tighten our belts.”

Flexible, Automated Processes

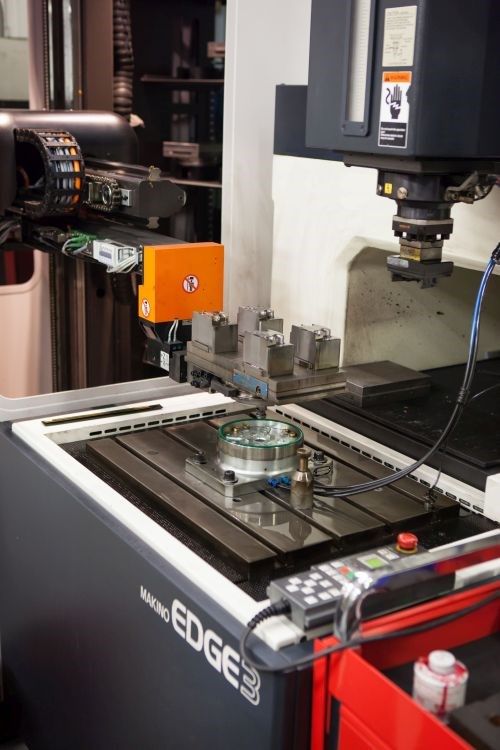

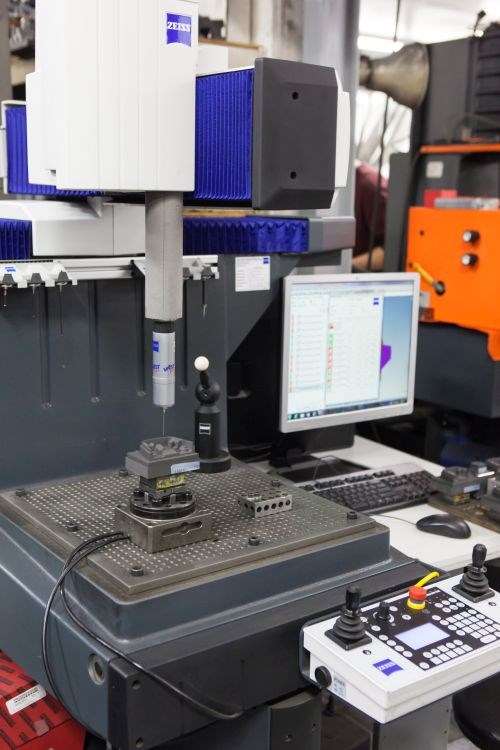

Keeping fixed costs low also enables Diamond Tool to open up its pocketbook when required, even during slow periods. One example was the company’s investment in its first robot in 2010, a time when its own future and that of the broader industry were by no means certain. Paired with a Roku-Roku graphite machining center and two sinker EDMs from Makino, the Workmaster carousel from System 3R USA LLC dramatically transformed the shop’s electrode production and laid the foundation for future automation in that area. “We were all awestruck by how much unattended time we could get,” he recalls, adding that plans are in the works to similarly automate core and cavity production.

That will be difficult to achieve, but Smith says he’s confident the effort will pay off. Beyond raw productivity, one of the chief reasons why is that capacity filled by robotics can be flexed as needed without adding or losing people. This makes it easier to maintain consistent staffing levels and improves job security, because letting a robot sit idle is preferable to letting go of talent. Layoffs and hourly cutbacks are still possible, of course, but would likely be far less severe than in the past. As Smith puts it, “We don’t have to send the robot home when things are slow. We can just shut it off.”

Keeping people busy in the meantime shouldn’t be much of a problem, Smith says. Slower periods provide an ideal opportunity for training, he explains, and Diamond Tool took advantage of the last recession to embark on a major cross-training initiative. Similarly to the addition of robotics, the resulting flexibility makes the company far better equipped to adapt in a highly cyclical market. This flexibility is important enough that cross-training remains a top priority, even though the shop is humming these days. “It’s hard to train people when we’re busy, but we make it happen anyway,” Smith says. “Our goal is to have every employee proficient in at least two areas, but in many cases it’s now three or four.”

A Frame of Reference

Throughout all of these efforts, Diamond Tool leaned heavily on a community of like-minded peers for ideas, support and feedback, Smith says. It continues to do so today. One source of wisdom is the Paradigm Group, a consortium of non-competitive CEOs leading businesses ranging from furniture stores to insurance companies that periodically gather to critique one another’s operations. “Business is business, and there’s always a lot to learn,” he explains when asked what such companies can teach a moldmaker. He cites the aforementioned drive to keep overhead low as just one example.

Even more valuable is the window into other moldmaking operations provided by the American Mold Builders Association (AMBA). Connections made during Diamond Tool’s 25-year membership in the organization’s Minnesota chapter have proven invaluable on a number of occasions, Smith says. One example is the installation of the shop’s first robot, which it purchased from a fellow member. The organization also provides a valuable frame of reference. For instance, the AMBA offers a sample payscale, based on member feedback, that the shop uses to ensure it’s fairly compensating employees. In another example, an AMBA benchmarking survey revealed that Diamond Tool is in the 99th percentile among members for efficient use of available floorspace. “I can’t say enough about the benefits of being in the AMBA,” Smith says. “There’s just a wealth of information there, and we’re all pretty open to helping each other out with common problems.”

Related Content

Five-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

Read MoreDevelopments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

Read MoreQuality Tool & Die Enhances Performance With Advanced EDM and Milling Technologies

The adoption of Mitsubishi wire and sinker EDMs, along with the OPS Ingersoll five-axis milling machine with automated cells, has enabled unmanned operations and improved precision. As a result, QTD has expanded its facility, grown its workforce and increased its business by 10-15% annually.

Read MoreTool Paths, ERP & Improving Efficiency in Your Toolroom: What Did You Miss in February?

We covered a variety of topics in February. From tool paths to ERP and PTXPO coverage, we hope you didn’t miss anything but here is your cheat sheet if you did.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More