Auxiliary Equipment

Workpiece Clamping Systems Designed for Moldmakers

IMTS 2024: Modular and standardizing clamping system options optimize workpiece setups with high accuracy and high clamping force.

8 Mold Design Decisions That Impact Automation

Making the right decisions during eight key mold design phases will avoid automation problems and save money on price, installation and operation.

Read More5 Questions to Ask Before Instrumenting a Mold

Instrumenting an injection molding machine with sensors can be a daunting task. It is a huge investment, after all, so how do you ensure that it will pay off in the end? The key is knowing the right questions to ask before you even begin. Here are the 5 most important questions to ask in chronological order.

Read More8 Ways to Increase Mold Life

A checklist of molding machine settings and preventative maintenance actions that improve mold longevity.

Read MoreVIDEO: How Water Flow Monitoring Optimizes Mold Production

MoldMaking Technology Editorial Director Christina Fuges and Progressive Components' Rebecca Hamstra discuss why monitoring water flow in injection molds is important.

Read MoreTooling: ‘Eco-Friendly’ Rust Remover & Preventative

Water-based product from iD Additives removes rust and prevents its formation.

Read MoreDatabase Helps Molders Limit Molding Out-of-Spec Parts

Mobile Specs offers a large, searchable database online and in app that provides molders with processing parameter set points for thousands of molding materials. Molders can use the site to reduce molding out-of-spec parts.

Read MoreStandard Hot Runner Cable Range Extension

Hasco is now offering its H12251 cable in two different lengths and four different wiring standards.

Injection Molding Technology Training Seminar Coming in August

Injection Molding Technology – Materials, Processing and Design Considerations is a seminar that will be held August 22-23 in Denver, Colorado, and is suitable for both experienced and inexperienced injection molding professionals.

Read MoreVacuum Units Offer Multiple Benefits

CUMSA has two new vacuum devices, the Double Action Vacuumjet (VB) and the Smart Vacuumjet (SV), at NPE2018.

Read MoreMold Shot Counter Automates Data Entry for Samsung Electronics

Samsung Electronics says that the benefit of eShotLink from Emoldino is that SE knows the location and status of its molds.

Read MoreSpray Washer Suitable for Large Molds

The Ransohoff Mega Jet Pressure Blast has a delivery system that CTG says is ideal for intricate details on machined parts.

Read MoreFive-Axis Rotary Table TAP Suitable for Small Vertical Machining Centers

Exsys Tool Inc. says that its five-axis rotary table tap enables users to upgrade vertical machining centers without incurring the expense of a new machine.

Read MoreLED Light’s Multi-Drive Feature Protects Light from Excessive Heat Damage

The LXE300 from Smart Vision Lights is the company’s brightest linear LED light.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

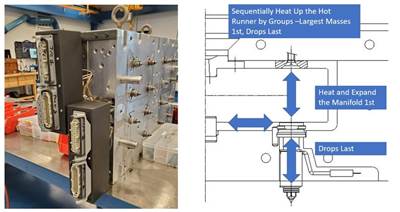

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Limiting Stress Limits Chances of Plastic Part Failure

Molders can reduce excessive stress in plastic parts with a deeper understanding of part design, mold design and material selection.

Read MorePutting Recycled Plastics to Work

Haidlmair discovered that if recycling is done correctly, the difference between virgin and recycled plastic material is minimal.

Read MoreTechnology Showcase: Case Studies for MoldMaking

It’s time for another foray into past case study features that have been published in MoldMaking Technology Magazine.

Read MoreAmerimold 2017: Plastics Exhibitors Promoted Products, Too

Amerimold had it all this year—or should I say it had MORE than ever before. While metalworking tools, materials and systems reigned supreme, the plastics side of the equation was also well represented.

Read MoreMoulding Expo 2017: More Than Just Hammers, Pliers and Saws

The International Trade Fair for Tool, Pattern and Moldmaking opens its doors today.

Read MoreSLIDESHOW: Technology Showcase, Amerimold Product Showcase

This is our industry’s show, and this week we bring you yet more previews of what you can expect to find as you walk the aisles of the biggest Amerimold Expo yet.

Read MoreHot Runner Systems, Controllers, Auxiliary Injection Unit Exhibitions

Mold-Masters exhibits a wide variety of new and enhanced systems and technologies at K Show like the TempMaster manifold plastic leak detection, the PET-Series two-stage hot runner system and Fusion Series G3.

Advanced Thermal Control

Integrating heating and cooling into the mold helps improve injection-molding control and flexibility.

Read MoreSLIDESHOW: Technology Showcase, After K

By all accounts K 2016 was a success. According to show management, attendees were delighted with the wealth of new technical developments presented by raw materials producers, machinery manufacturers and producers of semi-finished and technical parts. Here are some technology highlights.

Read MoreIncorporating Robotics

Consider robots in part and mold design, and molding processes to increase part quality and meet growing customer demands.

Read MoreA Hi-Tech Molding Machine in Action

Check out this video taken during the official opening of Hi-Tech Mold and Engineering's new Technology Center. It shows a fully automated Engel duo 3500-ton "smart" molding machine demoing (dry) a Hi-Tech mold for an interior automotive part.

Read MoreAmerimold is for... Achievers!

Following up on my blog from last week about our Amerimold Expo, which will be held June 15-16 in Novi, Michigan, I thought I’d call out some aspects of the event that will surely be of interest to our moldmaking audience. Why? Because moldmakers are achievers.

Read MoreA Mold Shop OEM

Years of helping customers save time and money in liquid silicone rubber (LSR)—a material that involves very different considerations from plastics—has led this shop to develop its own product line.

Read More

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)