2015 Leadtime Leader Awards Honorable Mention: Dynamic Tool & Design - Committing to a Scientific Process

This shop’s recent strides in mold qualification mirror an ongoing transition to a more systematic approach to mold manufacturing. Meanwhile, a culture of ownership ensures a full buy-in from veteran employees as well as fresh talent attracted through extensive workforce development efforts.

Although Dynamic Tool & Design is as concerned about the skilled labor shortage as any other mold manufacturer, this company can offer prospective employees something that most competitors can’t: an ownership stake. Since 2010, when Dynamic Tool adopted an employee stock ownership plan (ESOP), “growth from the ground up” has become far more than just a vague, guiding principle. It’s part of the company’s very structure.

Giving employees a stake—and perhaps more importantly, a say—in how things are done helps identify new opportunities for efficiency, says Dave Miller, company president. Beyond that, ESOP helps keep people engaged and motivated in an environment where much of the problem-solving traditionally performed by shopfloor toolmakers has moved upstream to the design department. Rather than feeling as though they need to surrender to the process, these employees actively shape it, often receiving formal recognition for their input. Meanwhile, new investments in apprenticeship and increased collaboration with local educational institutions ensure that the company’s most valuable resource is also a renewable one.

If recent developments are any indication of the pace of future change, employee input and new hires will be sorely needed in coming years, Miller says. Those developments go beyond advances in the shop’s manufacturing process. Just last year, the company opened a new technical center dedicated specifically to mold qualification, including turnkey projects on customers’ own equipment. This facility is the culmination of efforts to set the mold sampling side of the operation on the same path as the highly automated manufacturing side. That is, to institute a scientific process, one in which a given set of inputs leads to predictable, repeatable and measureable outputs.

These developments paint a picture of a shop that’s managed to not only ramp up its capabilities, but also institute the right culture for taking full advantage of those capabilities. All in all, they make Dynamic Tool & Design more than worthy of recognition with the Honorable Mention title in this year’s Leadtime Leader Awards.

Early Adopter

Recent changes can also be viewed as natural extensions of a winning formula that’s been in place for a long while at this Menomonee Falls, Wisconsin, operation. ESOP, for example, would never have been instituted if the company’s previous leadership didn’t recognize the value of its people, says Miller, who came on board as a designer in 1988 and became president in 2013. “They always ran it like a family-owned business,” he says about John Lau and Irv Fischer, who founded the company in 1976. “They got a kick out of building this company up, and they wanted to give back to the people who made that happen.” He also credits Lau with developing a close relationship with Waukesha County Technical College (WCTC), which has supplied a relatively steady stream of apprentices for decades.

The shop’s approach to manufacturing has similarly deep roots. A look at the shop floor reveals a heavy focus on automation, with robots tending virtually every machine not dedicated to turning, grinding or roughing large blocks. That includes not only graphite mills and sinker EDMs, but also hard-cutting machines. This approach makes sense, given the shop’s specialty in close-tolerance, high-cavitation molds that require relatively high volumes of interchangeable inserts. At first, however, such technology wasn’t a requirement for this work; it was a gateway to it.

Tom Andrews, plant supervisor, says he’s pretty sure Dynamic Tool was among the first mold manufacturers in Wisconsin to implement robotics when it made its first purchase in 1997. What’s more, he and the rest of the team were relatively well-prepared for that investment because the shop had been leveraging unattended machining since about 1980. This was possible not only through the early adoption of tool-changing CNC mills and EDMs, but also the development of a homegrown, 2.5D programming system that enabled plotting tool paths in advance to run all night. In the days before widespread use

of commercial CAM software packages, this strategy provided a significant edge, he says. Perhaps more importantly, it laid the foundation for a more modern, more scientific process that the company still relies on today.

A Scientific Method

That’s not to say things haven’t changed on the shop floor. The company is currently working to implement on-machine probing cycles to improve throughput and reduce pressure on quality control resources, to name just one example, and equipment is updated regularly. As its technology and processes evolve, Dynamic Tool continues to take on higher volumes of more complex work while reducing costs and lead times (the latter averages 14 weeks today, versus 16-18 weeks a decade ago).

Yet, the basic philosophy is essentially the same as it was 20 years ago, Andrews says. The primary difference is that the company’s capabilities and experience have caught up with its thinking. Mold designs and machining strategies are finalized prior to cutting any steel, and the shop relies on technology over human hands wherever possible to limit variation. A standardized, repeatable and predictable process, with results verified through part inspection at virtually every stage, enables Dynamic Tool to achieve virtually 100-percent on-time delivery of fully qualified tools.

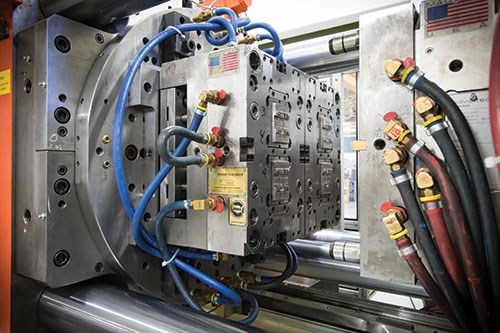

More recently, Dynamic Tool has made extensive efforts to apply the same philosophy to mold sampling. Although the shop has had presses in-house for more than a decade, today’s customers demand far more than proof that a mold will successfully eject parts, particularly if that mold will run overseas. Rather, they expect a ready-to-run tool and a bulletproof process. As a result, the shop’s press operators can’t adjust molding parameters to ensure a quality part, in the same way that machinists can’t deviate from CAD models on the manufacturing side. “We have to make the tool fit the process,” Andrews explains. “We can’t make the process fit the tool.”

That means keeping all parameters within a specific window. Injection pressure, fill time, hold time, even ambient room temperatures—all must match the environment and machinery in the customer’s plant as closely as possible, Andrews says. If producing a good part requires going outside that window, the tool must be sent back to the shop for adjustments.

Although efforts to adopt scientific molding have been about four years in the making, the shop wasn’t fully equipped to provide these services until late 2014. That’s when it opened a $1.3 million, 17,000-square-foot facility expansion that houses five molding machines as well as various supplemental equipment, such as gages to measure water pressure, flow at the press, heat removal rate and so forth. Clamping forces ranging from 80 to 650 tons, as well as two-shot capability, cover the vast majority of applications, Andrews says. The facility also offers plenty of space for customers to bring in their own equipment for turnkey projects, a common scenario when jobs call for end-of-arm tooling or other automation.

Dynamic is now fully equipped to apply the scientific sampling knowledge it’s developed during the past few years. Every tool undergoes a multi-step process: machine verification (choosing the right equipment for tryout); dry cycle (ensuring basic mold function); initial process development (establishing first shots); in-depth process development (establishing parameters within the molding window via rheology studies, mold balance, gate freeze, etc.); an eight-hour acceptance run; and finally, tool measurement and CPK part inspections. Each step involves an extensive checklist, and everything is recorded. “Tracking everything is a big part of the scientific aspect of this,” Andrews says. “We set a process, we follow it, and we document everything we’re doing. The customer needs to be able to just plug in the numbers we give them and make it work.”

A Culture of Ownership

As effective as modern manufacturing strategies have proven to be, setting a process and following it can be difficult for skilled toolmakers who pride themselves on problem-solving. At Dynamic Tool, however, shopfloor employees have an incentive to actively contribute to process development and improvement. That’s largely thanks to a significant cultural shift that began in 2010 with the adoption of an ESOP, Miller says.

Dynamic Tool’s founders set up the ESOP as an alternative to selling the company when they retired. Every year, the founders receive a portion of the profits in exchange for stock. That stock is distributed among employees based on salary, and it is held in a trust until they leave. “It’s essentially a retirement plan, but it’s not the whole package,” Miller explains, noting that the company also offers a 401(k). “The beauty of it is that no employee is putting money into this. It’s as if we were paying on a loan for a machine, but the company is essentially buying itself from the previous owners.” As of this year, the company is 98-percent employee-owned, he adds.

The basic idea behind ESOP is that employees will be more productive and engaged in the company’s overall success if they have a stake beyond their own paychecks. Early on, however, it became apparent that, in isolation, ESOP wouldn’t be enough to spur the sort of cultural change leadership wanted to see. “It’s not something that just happened,” Miller says. “We had to start changing our philosophy on how we managed jobs and allow employees to step up and take responsibility.”

Project leaders no longer dictate tasks from on high. Rather, shopfloor employees are invited to job planning meetings to offer feedback on their specific portions of the build. This is good not just for morale, but for the overall process, which reaps the full benefit of individuals’ often deep expertise in particular aspects of the build, Miller says. For instance, perhaps the CNC department really can mill a feature that the project leader assumed would be a better fit for sinker EDM.

This strategy isn’t the only contributor to the shop’s culture of ownership. Lori Phillips, marketing director, was hired on a part-time basis last year to help attract new business, but her focus has since been directed inward as well. “We’d like to make everybody feel great about coming to work every day,” she says.

One such effort is a bi-weekly, internal newsletter that aims to build camaraderie and ensure company-wide communication. For instance, the newsletter highlights the winner of the ABCD (Above and Beyond the Call of Duty) Award. Employees nominate one another for extra effort and innovative ideas, and winners receive a gift card and recognition on the “ABCD Wall of Fame” bulletin board. In another recent example, an idea from one of the toolmakers led to the creation of the Dynamic Cares Committee, through which employees recognize one another’s personal triumphs and tragedies alike with cards and gifts. Other ideas come from regular meetings hosted by the ESOP Association, a non-profit group that represents approximately 2,800 ESOP companies. During Employee Ownership Month in October, the company hosts various events and contests, such as a chili cook-off. In April, Dynamic celebrated 39 years of business with an anniversary cook-out, and employees were recognized for their years of service.

Fresh Faces

What Phillips calls “internal marketing” isn’t the only reason why her workload has grown from 10 to 30 hours a week in just one year. Particularly during the past few years, the shop has been focused on recruitment as well as employee retention and empowerment. For Phillips, that’s meant getting the word out about job opportunities through a new website and social media campaign. In fact, she says analytics reveal that the “careers” page is one of the most popular sections of the new site. She’s also been attending various career fairs and developing promotional materials for those events. The 60-employee shop currently has five new hires in training, amounting to one apprentice for every six journeyman toolmakers.

The story of one trainee in particular, Michael Nareski, embodies the future direction of workforce development at Dynamic Tool, Miller says. Like many others over the years, Nareski came to the company through WCTC. The difference is that he hasn’t graduated, and he isn’t technically an apprentice yet. At the time of this writing, he was still attending Menomonee Falls High School.

That’s because he’s the first to come into the company through WCTC’s dual-enrollment program, which is designed to give high school seniors a head start in their chosen fields and start earning college credits. He spends the majority of his days at WCTC and comes into the shop three afternoons per week to supplement his coursework with hands-on learning under the tutelage of senior personnel. Around the time this article is published, Nareski will graduate high school with a diploma and a CNC Operator Workforce Certificate from WCTC, where he’ll continue his studies with 22 credits already under his belt. Once he’s finished there, he’ll begin his apprenticeship at Dynamic Tool, which operates a paid, highly structured program that tracks progress and hours in different areas of the shop based on state guidelines.

Miller says the experience so far with Nareski has him and the rest of the team extremely excited about the future of dual enrollment. Excited enough, in fact, to leverage their WCTC contacts to put them in touch directly with local high schools and even middle schools. The hope is that these burgeoning relationships will provide the opportunity to get the word out about Dynamic (and manufacturing in general) through activities like student tours of the shop, thereby attracting more students to dual enrollment. “It really comes down to the enthusiasm that I see in Michael and the other young people in this program,” he explains. “At a pretty young age, they’ve really determined that this is what they want to do, and they’re going beyond what someone would normally do in high school. We like that enthusiasm and that drive.”

Related Content

MMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreHow to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

Read MoreHow to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

Read MoreRead Next

Above and Beyond the Call of Duty

For this year’s Leadtime Leader runner-up, the “ABCD” award is a key part of building camaraderie and ensuring a culture of ownership. Here are a few examples of recent winners.

Read MoreBeyond Indicating

The winner of this year’s Leadtime Leader: Honorable Mention award aims to use on-machine probes to not just find zero location, but to perform full part inspections. The machines themselves have proven more than capable, but the shop still faces other hurdles.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)