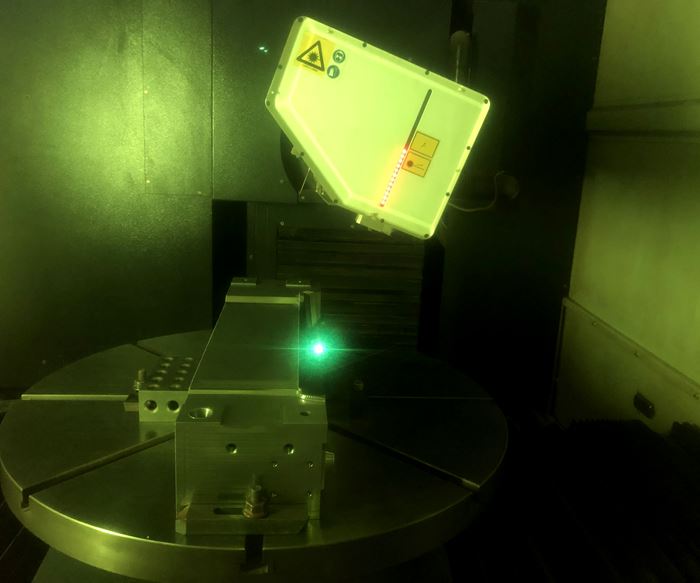

“Recognizing your manufacturing constraints and acting on them can lead to opportunity.” So says Tim Shamrock, sales manager of Custom Etch Inc., a company specializing in texturing and engraving for many types of molds, including injection, blow, compression, thermal pressure/vacuum and extrusion. In November 2011, Custom Etch became the first North American company to purchase an AgieCharmilles Five-Axis Laser 1000 system and a six-pallet loading system from GF Machining Solutions. Up to that time, Custom Etch used only the traditional transfer and photo-printed acid etching processes, which are exacting manual processes requiring a high level of expertise.

Shamrock, who has many years of practical experience in mold texturing, shares his perspective on the advantages of using laser ablation technology to texture molds, including faster turnaround, more uniform patterns, higher precision and more. In addition, he sheds light on the continued relevance of traditional chemical etching.

Understanding Texturing Tactics

When determining what texturing method to use, it is important to first understand how they are applied.

Shamrock explains that the traditional method of acid etching requires a lot of time-consuming upfront preparation, including disassembling the mold, cleaning all residual oil from all surfaces and manually laying out texture limits (where texture stops). The technician then begins wrapping the exterior of the mold with tape and/or a spray masking product to protect the areas that will not be textured. This is followed by sandblasting of the exposed surfaces so that the texture pattern will adhere to them. The texture pattern is printed out, like a template, in the form of a film or wax transfer, and the technician then manually applies it using the pattern transfer process. “It can take several printing jobs, going back and forth and measuring both halves of the mold to make sure the textures matches perfectly across parting lines,” he stresses. Then acid is applied to, in effect, chemically mill away metal and etch the pattern into the mold.

Once the acid etching process is complete, the mold is sandblasted again to remove any remaining residue from the acid etching process and for gloss adjustment, if necessary. The mold parts are cleaned and if there are stains or damage from over-blasting non-textured areas, repairs are made, inspections and quality control steps are taken, and components are packed and shipped back to the customer. From start to finish, using the acid etch method can take, on average, four to five days for simple pattern applications and up to two to three weeks for more complex pattern applications, such as for automotive lens molds. Some customized patterns can take even longer.

“With laser texturing, not only do we not have to disassemble the molds to establish precision textures, but only minimal cleaning is needed to remove mold saver (product applied to molds to protect them when not in production) and no sandblasting or taping is required,” Shamrock says. Basically, Custom Etch’s engineering department inputs the 3D mold cavity data and chooses the texture file images that match the desired patterns. Textured surfaces are mapped using UV mapping software and verified for correct texture direction and orientation. Once complete, the CAM program is uploaded to the laser texturing machine for processing. GF Machining Solutions recently introduced new software, including Smartpatch, which allows examination of the pattern before it is laser machined onto the mold, and Smartscan 3D, which provides UV mapping for texture applications and 3D simulation to optimize every patch that is machined.

“Because of laser texturing technology, we experienced a huge shift from using all chemical etching at our facility to using 10 percent laser texturing almost immediately, and since then that percentage has increased year over year,” he says. “Currently it is at a solid 35 percent, but it has reached 50 percent. The number fluctuates based on each job’s texturing requirements.”

Laser Ablation Advantages

Timing and quality are paramount to the molding industry, but Shamrock points out that mold texturing is typically one of the final processes in a truncated timeline. “Minimizing the processing timing constraint using laser ablation technology allows us to fulfill large orders efficiently and with the highest quality,” he says. “It increased our capacity for future programs as well. For example, in 2014 we realized that precision application of patterns using laser technology would be beneficial in high-polished substrates like those found in automotive lens applications.” He says this is because there is no risk of damaging the highly polished surfaces because the laser positioning is so precise, and its radius is very small. Texture is applied with short, pulsed lasers using between 30 to 100 W of power. Additionally with laser ablation, multiple patterns can be applied to the same substrate all in one setup.

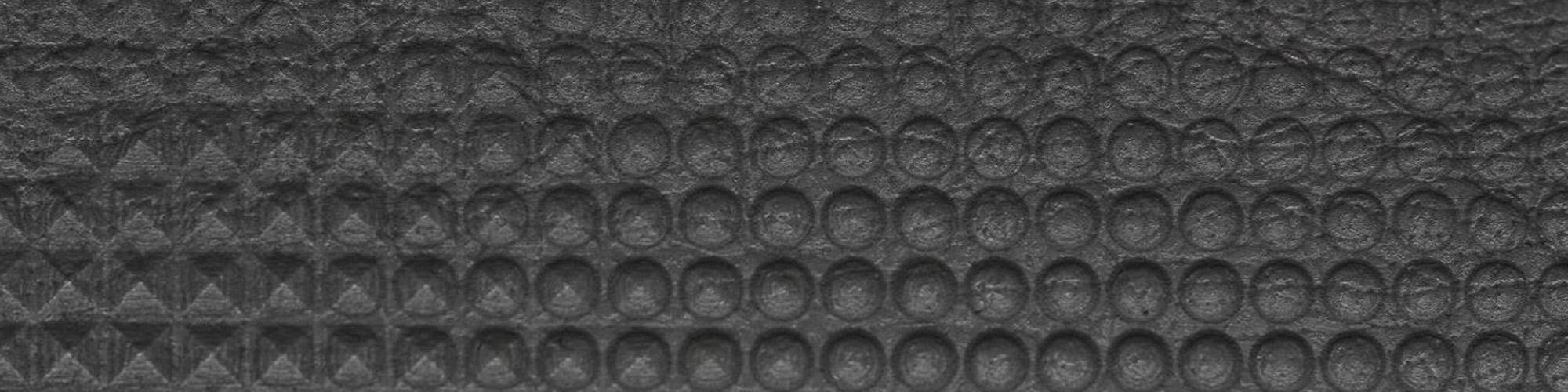

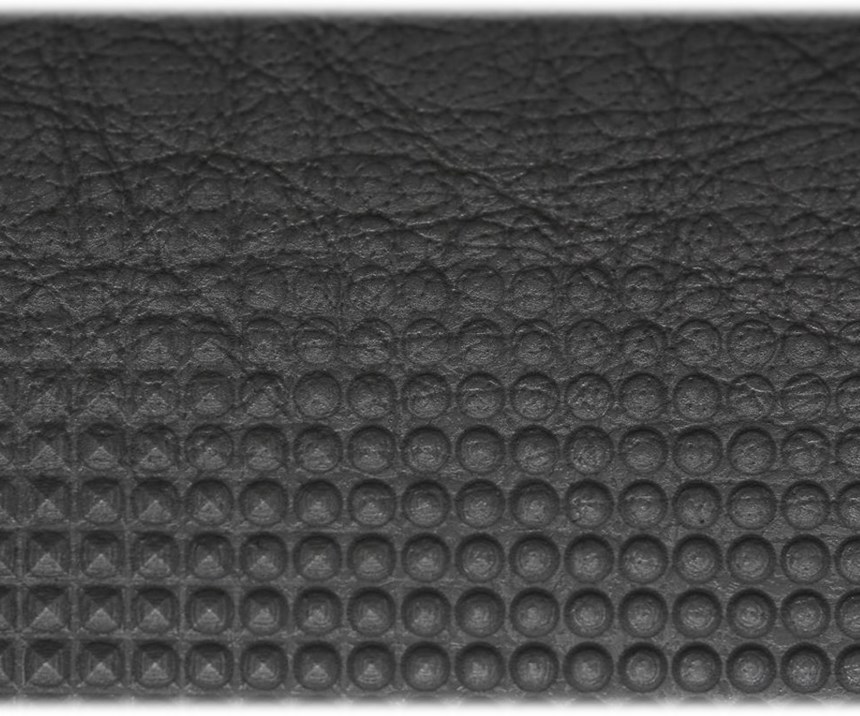

Texturing at its core is the process of changing the surface finish of the substrate

Because laser ablation technology eliminates so many tedious manual steps, and the overall laser finish provides uniformity, consistency and better diffusion properties, Shamrock says processing time for the lens molds has been reduced from two to three weeks using traditional texturing methods to only five to 10 workdays. When processing bottle molds, Custom Etch reduced the texturing process to two hours from eight hours for each mold. The use of automation further increases throughput, he says.

Laser systems work from digitally created files versus using a print, and/or paint pens in multiple colors, to manually map the areas to be textured and with what pattern(s), so critical details can be discussed in a virtual meeting with customers via Skype, GoToMeeting or other means using CAD files. “We have reduced travel time while ensuring that everyone involved can participate from anywhere,” Shamrock says. “We work directly off the mold data to address molding concerns with the applied texture. Efficiency and accuracy increase tremendously because rendered parts can also be reviewed, rotated and aligned for pattern congruence without the need for further interpretation. The data is both available and transferable and it can easily be incorporated into current texture maps (as GIF and TIM files).”

Considering most textures are aesthetic, it is a big deal to have everything look the same

Laser ablation also provides the ability to apply texture while leaving a consistent finish across dissimilar mold materials, including welds. Shamrock explains that many times, molds will be constructed from different materials to employ the different properties specific to the material like cooling, hardness, venting and to prevent wear, galling and corrosion. Also, welds, which may be compatible to the primary substrate, may not necessarily have the same composition and properties as the primary substrate, he says. Texturing at its core is the process of changing the surface finish of the substrate and there are “recipes” for removing metal at a specified rate, leaving the surface with a desired finish. “These recipes are formulated to react with the chemical makeup of the metal substrate. Unfortunately, there are many substrate compositions that may require different recipes and to complicate things further, that desired surface finish may be similar but not precisely so,” he says.

“Over the decades, texture houses refined this process to minimize this; however, laser texturing removes material and the finish is the same. It doesn’t matter if it is H13 and P20 or aluminum and BeCu or a QC10 substrate with a QC10 weld. Considering most textures are aesthetic, it is a big deal to have everything look the same,” he continues, adding that laser texturing is also superior to acid etching on corrosive resistant substrates, 300 series stainless, Titanium, Nitride, EDM and other materials.

Finally, he notes several other time-saving benefits like the fact that multiple molds can be processed at the same time in the large format laser systems like the AgieCharmilles Laser 4000 5Ax (which has part size capability of up to 4000 by 3000 by 1500 mm and workpiece weight capacity of 50,000 pounds). “Laser texturing is a green process, because we do not use caustic materials that involve strict hazardous waste removal procedures,” Shamrock adds.

Accepting Laser Limitations

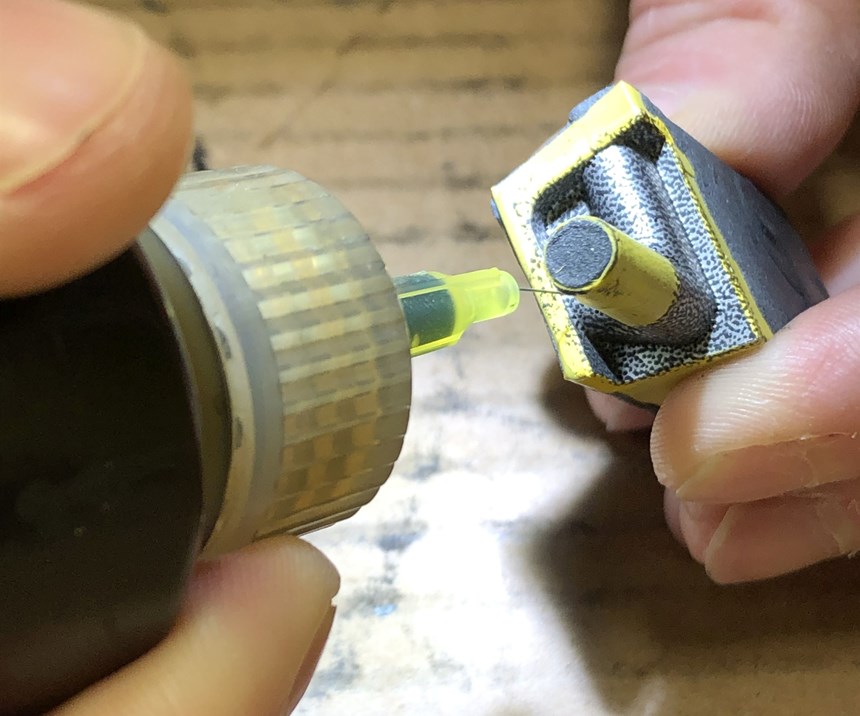

Shamrock says it should be noted that some of the large aluminum pieces Custom Etch works on can be done using laser ablation, but it is not as economical as acid etching. “Most of them have patterns that require significant metal removal,” he says. “Acid requires less time and resources to accomplish this. In fact, acid etching can be a very economical way of texturing certain jobs and so there will always be a need for the process.” An example is the lawn and garden or architectural markets where there is a demand for texturing to simulate stone/slate or flagstone on everything from flowerpots to flooring. “These patterns typically require depth of pattern of 0.010 inch to 0.025 inch of metal removal, which necessitates a series of etchings,” he explains. “However, the amount of time required to laser ablate would be much more due to the preciseness of the metal removal process. Experiences like this also gave rise to a hybridization of the texturing process. We can maximize the general efficiency of acid etching for depth and use the precision of laser ablation to detail the same pattern.”

In fact, acid etching can be a very economical way of texturing certain jobs.

Shamrock says at Custom Etch, the packaging and automotive industries are currently the biggest users of laser texturing technology. “We use laser texturing technology on about 90 percent of the packaging molds we process because most packaging applications require repeatability, efficiency and the ability to process a number of molds in a short timeframe,” he says. “If you're talking automotive lens molds, it's 100 percent laser.” Regarding the architectural products market, Shamrock says laser ablation has provided access to a larger pallet of digital pattern options that are not achievable using the manually applied acid etching process, so they are seeing an increase in laser applications for those customers.

Laser Precision Prevails

The exactness of laser technology has made it the optimum choice for mold texturing because of its quality and repeatability, according to Shamrock. “Because CAD files indicate precisely where the pattern layout is needed, we eliminate the chance of error.” While this is a strong argument for enlisting laser technology, he notes there is a functional benefit as well. “Traditionally, texture was held to a visual standard. Patterns were visually compared and inspected using a set of plaques. As patterns became more refined, so did the standards to inspect them. There were ways to manipulate the surface texture, but one was still limited with blast media and acid because 3D patterns and technical grains are not attainable with the acid process. “Texturing with acid has come a long way, but it still has many restraints,” he explains. “The main restriction is gravity. Acid etches downward. Yes, it can be pumped and rotated but it will still etch downward and then outward from newly exposed surfaces, leaving a radius and an undercut on exposed surfaces There are no 90-degree etchings. Instead, geometries become two-dimensional one level at a time.

We can now blend patterns, morph them and/or get as angular with them as we want.

“Laser texturing has few constraints,” he continues. “Today’s patterns, such as the Laser Tech 6000 Series developed by Tenibac-Graphion, offer many new applications using laser technology and we can control factors beyond just Surface Roughness (Sa), Texture Direction (Std) and Texture Aspect Ratio (Str). This is because the laser gives us many options to manipulate a pattern. We can provide a pattern with the same depth and roughness but with many different possibilities in direction, surface area and so on. This provides the end-user with options for friction, refraction, scatter, volume. We can now blend patterns, morph them and/or get as angular with them as we want.”

Today, Custom Etch has three Laser 4000 5Ax systems, three Laser 1000 Ax systems, a new AgieCharmilles Laser S 1000 U (part of a new series of digital, all-in-one five-axis laser texturing systems introduced earlier this year) and a Laser 1200 5Ax.

“Laser technology enables the user to address critical constraints in timing, quality and capacity,” Shamrock says. “More patterns can be applied, replete with directional changes (think of wrapping a patterned fabric over a three-dimensional surface. The pattern direction will change due to stretching and compressing to conform to the surface.), more seamlessly than ever before, and new markets will be opened to those who embrace the technology.”

Related Content

Questions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreHow to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreRead Next

New, five-Axis Laser Texturing System Offers Speed, Accuracy and More Geometric Options

Attendees at GF Machining Solutions’ unveiling of Laser S series say they are excited, impressed with speed and accuracy of mold texturing system.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More