VIDEO: Optimizing Mold Measurement with CMMs

Portable, shop-ready CMMs enhance precision, speed, and efficiency.

Tony Almeida Regional Sales Manager at Mitutoyo America Corporation shares how mold builders can achieve precise, efficient mold measurement using advancements in surface roughness testers and compact CMMs.

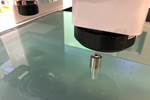

Portable surface roughness testers streamline the measurement process, allowing direct application on large or heavy molds. With single-button operation and vivid color displays, these devices ensure user-friendly experiences.

Also, compact CMMs like MiSTAR offer shopfloor readiness and cantilever designs that support the side loading of large workpieces. Equipped with touch panels and software integration options, they are ideal for operations as inline automation gains momentum.

On the software side, MiCAT Planner simplifies the programming process, converting complex CAD geometries into actionable measurement plans. This eliminates steep learning curves, helping moldmakers maximize efficiency.

Looking ahead, technological advancements in CMMs and software automation will significantly shape the moldmaking industry in the next five years, driving precision and productivity further.

Click here to check out more videos.

Related Content

-

Line Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

How to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.