High-Precision VMC With Unrestricted Five-Axis Machining

The Mikron Mill S 200 U is GF Machining’s vertical high-speed machining center well suited for tool and moldmaking and exact part production.

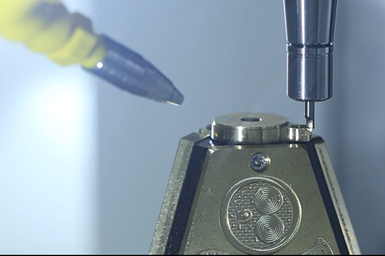

GF Machining Solutions highlights the Mikron Mill S 200 U, a vertical high-speed machining center with unrestricted five-axis machining capability, which is the result of its table design that provides interference-free part access. The machine is said to be designed for the highest precision and surface quality and is well suited for tool and moldmaking and other high-precision parts production such as watchmaking and micromechanics, electrode production, medical implants and devices and fluidics. For optimal vibration damping and machining stability, the Mikron Mill S 200 U is built on a polymer concrete base and incorporates a robust 50,000 rpm spindle along with a separate cooling circuit for all linear axes and the circular swivel unit.

Micromachining and small part precision is achieved with the use of low tactile forces in the Z-axis and precise laser optics for measurement of very small tool diameters ranging from 25 mm to 20 mm. Multiple tool storage configurations are available with 30, 60 or 150 tool positions, and the Mikron Mill S 200 U accepts a full range of automation and tooling solutions from GF Machining Solutions to further increase productivity.

Related Content

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

-

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.