2024 Moldmaking Insights: A Year in Review Part 2

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

3D Printing Innovates Hot Runner Manifold Design

Source | Hasco America Inc.

This article details a 3D-printed manifold technology that significantly improves color change efficiency for injection molding. The design features separate floating modules screwed onto a conventional manifold, allowing flexible cavity placement. The key innovation is its ability to eliminate flow shadows by dividing and merging the melt channel where the valve stem enters, preventing material trapping that typically causes color change issues. Testing showed the system achieved pure white material in the first cycle when changing from black to white ABS, with no deposits around the valve pin stem after four shots. This design enables 3-4 times faster color changes than conventional systems, resulting in long-term cost savings. Read the complete article online at: https://short.moldmakingtechnology.com/3DP-hot-runner-manifolds

Source | Progressive Components

How to Manage a CAD Library

This article explains the five key priorities of an effective CAD library. First, establish a streamlined main library with commonly used, approved components. Second, create secondary libraries for occasional-use items and custom components. Third, maximize data reuse by saving repeatable tasks and leveraging supplier-provided features. Fourth, implement clear standards for tolerances, orientation and colors without over-restricting design flexibility. Finally, automate bill of materials (BOM) population directly from 3D designs. This organized approach reduces time spent on repetitive tasks, minimizes errors and allows designers to focus on critical cavity and core details. Read the complete article online at: https://short.moldmakingtechnology.com/manage-CAD-library

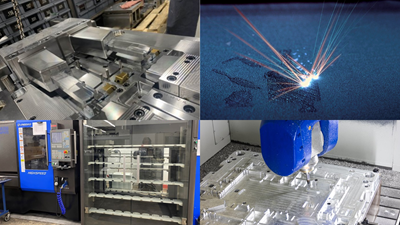

Ultra-Fast Femtosecond Laser Texturing Helps Produce EV Lighting Lens Molds

The electric vehicle industry is driving innovation in automotive lighting through edge-lighting systems, which use LEDs around lens edges for illumination. This article details a Ultra-fast femtosecond laser texturing technology that can meet the required special micro-faceted patterns in plastic lenses that can't be achieved through conventional moldmaking methods. This solution allows manufacturers to test patterns directly on plastic lenses before applying them to production molds. It creates sharper, more intricate details than traditional nanosecond lasers and produces minimal heat-affected areas. While costly, the system's dual-platform capability allows shops to use both laser types, expanding their application range and reducing product development time. This advancement supports the growing "shy tech" trend in EV design, emphasizing cleaner, button-free interfaces. Read the complete article online at: https://short.moldmakingtechnology.com/laser-texturing

Mentorship Matters: A Fresh Perspective from a Young Female Newcomer to a Mature Male-Dominated Industry

Jane Huot, a 23-year-old mold designer and project manager, recounts her one-year anniversary with Accede Mold & Tool this past summer and her first business trip. Jane traveled from New York to Arizona with Camille Sackett, VP of Sales & Marketing, and Angie Steingass, Marketing Manager, to a conference sponsored in part by Accede geared for women in the rubber and plastics industries. Jane assisted with the setup and staffing of her company’s exhibit and attended conference sessions. After the conference, Jane shadowed Camille on sales visits to customers’ facilities. She shares the indelible mark this experience left on her professional growth. Read the complete article online at: https://short.moldmakingtechnology.com/moldmaking-mentorship

How to Make Data Work for Mold Productivity and Performance

Source | SyBridge Technologies

Manufacturing is evolving through digital integration, with a focus on connecting scattered data across the product lifecycle through a "digital thread." According to SyBridge Technologies' VP Charlie Wood, this approach enables digital twins and machine learning applications. Two key developments are highlighted: digital design libraries, which use parametric design for standardized components, and advanced conformal cooling through additive manufacturing. The latter can significantly reduce cycle times and improve mold efficiency through optimized cooling channels. Machine learning is increasingly important for leveraging manufacturing data, helping with defect prediction and design optimization. The industry faces challenges in building robust data infrastructure while maintaining manufacturing expertise alongside software development skills. Read the complete article online at: https://short.moldmakingtechnology.com/data-productivity

Navigating the Future of Mold Design and Manufacturing

This Q&A with a mold designer discusses key industry challenges, including staffing shortages, training needs, shortened lead times and increasing competition from overseas manufacturers. He shares efforts to build local manufacturing interest through school outreach, though he faces resistance from high schools prioritizing college paths over direct employment. He also highlights how 3D printing has enhanced design capabilities by enabling physical prototyping. Regarding future trends, automation is expected to significantly impact the industry, particularly in adapting to one-off parts production. While AI's role in design is mentioned, he remains cautiously optimistic, suggesting it will enhance rather than replace human designers. The article also notes improvements in CAD software user experience and accessibility. Read the complete article online at: https://short.moldmakingtechnology.com/future-of-moldmaking

Quality Tool & Die Enhances Performance With Advanced EDM and Milling Technologies

Source | MC Machinery Systems

The article details the success story of Quality Tool & Die (QTD), a Pennsylvania-based company that transformed through strategic equipment investments. After being acquired in 2005 by Brad McDowell and Chad Kearns, the company overcame initial financial struggles and evolved from a manual operation into a sophisticated tool-building enterprise. Key to their transformation was the adoption of Mitsubishi EDM machines and an OPS Ingersoll five-axis milling machine with automation. The new equipment, particularly the Mitsubishi SV12P sinker EDM with artificial intelligence and the five-axis mill, significantly improved productivity by enabling unmanned operations and reducing electrode consumption. The company has grown 10-15% annually and expanded to 30,000 square feet, now employing 30 people across tool shop and injection molds divisions. Read the complete article online at: https://short.moldmakingtechnology.com/1124-mmt-Quality

Source | Rocklin Manufacturing Co.

Reasons to Use Fiber Lasers for Mold Cleaning

Contaminants like rust, dirt, grease and oil can severely impact the injection molding process, leading to surface defects, increased mold corrosion and heightened wear and tear. This article reviews a solution to prevent these issues that cause costly damage and downtime. Traditional cleaning methods, such as chemical, ultrasonic and steam cleaning, have their drawbacks, including potential damage to mold surfaces and inefficiency with temperature-sensitive molds. Fiber laser cleaning offers a fast, precise and reliable alternative. It minimizes cleaning risks by transforming contaminants into vapor or dust without damaging the mold. The portable laser cleaner, weighing 50-60 pounds, allows for efficient on-site cleaning, extending mold life and reducing maintenance needs. Read the complete article online at: https://short.moldmakingtechnology.com/1024-mmt-rocklin

Complex Mold, Versatile Piece of Engineering Enhances Golf

Source | Kid Caddie

This story introduces Ben Fairbanks, an innovator from South Dakota, who created the Kid Caddie to make golf more inclusive for families. This accessory, which doubles as a stroller, allows golfers to carry 18 clubs and enjoy the game with their children. Inspired by his daughter’s birth, Fairbanks developed the Kid Caddie through extensive testing and 3D printing. Despite initial challenges with molders, he built a strong interest base and partnered with Premier Plastics and Prairie Tool to produce the Kid Caddie. The product gained significant attention on social media and debuted at the PGA Show. The Kid Caddie aims to revolutionize golf by making it accessible and enjoyable for families. Read the complete article online at: https://short.moldmakingtechnology.com/complex-mold

The Lowdown on Guided Ejection Systems

This article explains how guided ejection systems, which include guide pins and bushings within the ejector housing, significantly extend mold longevity by supporting, guiding and aligning ejector plates and connected components. These systems prevent the weight of ejector plates from causing wear and damage to mold parts, ensuring proper alignment and movement. They are particularly beneficial for molds with heavy ejector plates, complex ejection components or long ejector strokes. While they increase mold costs, guided ejection systems reduce downtime and repair expenses by preventing issues like flash and component wear. Mold base suppliers offer various sizes and configurations, allowing customization to meet specific mold design needs. Read the complete article online at: https://short.moldmakingtechnology.com/1124-mmt-Injection-Mold

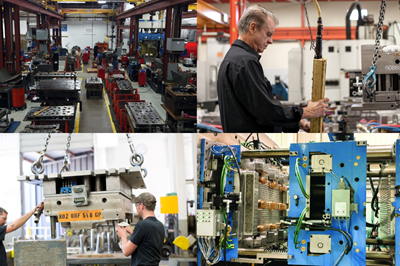

CAD/CAM Software Reduces Delivery Times by 70% With a Six-Month ROI

Source | TK Mold & Engineering

This article shares how TK Mold & Engineering invested in advanced CAD/CAM training so everyone, from estimators to designers to CNC and EDM techs, can use the software more efficiently. With a team of 25, the company operates in two facilities, designing and building up to six tools per month. They also offer maintenance, repairs and low-volume custom injection molding. Their customers span the automotive, consumer goods, aerospace and medical sectors. TK Mold uses integrated Cimatron CAD/CAM software to streamline workflow and improve productivity. The company is ITAR registered and ISO 9001:2015 certified and has received multiple awards for its contributions to the industry. They are also active in mentoring young toolmakers through various apprenticeship programs. Read the complete article online at: https://short.moldmakingtechnology.com/CAD-CAM-reduces-time

Source | PLASTICS analysis of U.S. ITC data

Shift in U.S. Mold Imports: Emerging Countries Gain Ground in Market Share

This second quarter reports reviews data showing that from 2015 to 2017, U.S. mold export values rose steadily, peaking at $624.2 million, but then plateaued and slightly declined. Imports increased until 2018 and then stabilized, leading to a growing trade deficit with a 4.1% CAGR over the past decade. Domestic mold production has been volatile, influenced by economic cycles and rising imports. Emerging countries like Thailand, South Korea and India have gained U.S. market share, presenting both challenges and opportunities. The U.S. remains a net importer of molds, with imports consistently outpacing exports. Economic policies, energy costs and international competition continue to impact the U.S. mold manufacturing sector. Read the complete article online at: https://short.moldmakingtechnology.com/US-mold-imports

Related Content

How to Use Hot Runner Balance in Mold Qualification

If you are interested in the impact of system and hot runner balance on part quality, the causes of unbalanced hot runner systems and short shot parts, the procedure for measuring system balance and the impact of application specifics on system and hot runner balance expectations, then tune into this on-demand webinar.

Read MoreHot Runner Nozzles: Internally Heated Vs. Externally Heated

Why internally heated nozzles make more economic sense.

Read MoreHow to Overcome Five Common Hot Runner Cable Connection Problems

Here are some simple solutions for pushed-back or bent pins, pushed-back inserts, high amp deterioration, loose or broken latches and missing or loose ground wire connections.

Read MoreHow to Transition From a Cold to Hot Runner Mold

Reducing cycle time and costs while also freeing up your machines for other projects are advantages gained by using hot runners that no one can ignore. But where does one begin transitioning from cold to hot runners?

Read MoreRead Next

MoldMaking Technology's Most-Viewed Profiles of 2023

MoldMaking Technology's profiles feature insightful interviews and stories about professionals and their experiences in the moldmaking industry. Here are the top five most-viewed profiles of 2023 based on Google Analytics.

Read MoreMoldMaking Technology's Most-Viewed MMT Chats of 2023

MMT Chats—hosted by Christina Fuges—is a conversational video series uniting moldmaking professionalss to talk about manufacturing, tooling, and moldmaking methods. Take a look at our top five most-viewed MMT Chats based on Google Analytics.

Read MoreMoldMaking Technology's Most-Viewed Case Studies of 2023

MoldMaking Technology’s case studies present a shop’s problem, solution and results in thorough detail. Take a look at our top five most-viewed case studies based on Google Analytics.

Read More