Share

Delta Mold Inc. has manufactured 17,500 unique molds over the last 44 years. With a dedicated repair program, Delta Mold services include on-site evaluations and support, as well as 24-hour repairs and fast parts delivery to keep customer operations moving forward. Photos Credit, all images: Delta Mold Inc.

Share a little about Delta Mold Inc.’s history.

Ernie Young, president, Delta Mold Inc.: Delta Mold was established in 1978 by Rudy Mozer, the founder of Delta Technologies. Delta Technologies, founded in 1952, was our parent company until 2016, when it was sold to US Farathane LLC. Rudy passed away in 2014 and the Mozer family retained Delta Mold. The current CEO is Eric Mozer; he and his brothers are the primary shareholders.

The company started to service the plastics business emerging in the southeastern U.S. The founders located the business in Charlotte, North Carolina, to take advantage of the manufacturing opportunities and support customers. Initially, Delta Mold focused on the expanding plastic industry’s needs for products such as personal computers, keyboards and printers that were exploding in the market in the late 1970s. Then, as the manufacturing of these products went offshore, Delta Mold began to focus on large plastic parts for products such as televisions, lawn and garden tractors and vehicles, recreational vehicles such as golf cars and the heavy truck industry.

Delta Mold manufactures multiple automotive components. Still, we hold a strong presence in the nonautomotive market. The nice thing about Delta Mold is that one day you might be working on a riding lawn mower, and the next, you might build a boat hull or a trash can. We’ve built 17,500 molds in the last 44 years; each one has been unique. In 2022 our annual revenues were greater than $24.7 million.

With up to 40-ton overhead cranes, Delta Mold can produce injection molds from 50 to 6600 tons, including spotting and final assembly.

What are the company’s core values?

Young: Our core values start with safety, which ensures a healthy work environment. Next, we focus on dependable products and technology that sustains efficiency and leads to superb quality. Finally, employee engagement and career development to retain top talent and continuously sharpen our skills. These values guide the team, have nurtured our success for nearly 45 years and have helped us cultivate long-term partnerships with our customers, suppliers and on-site teams.

What do you look for in an employee?

Young: The first two things we look for when hiring new team members are availability and accountability. They don’t need experience in injection mold building, but if they’re willing to work every day to learn and improve, they can work at Delta Mold.

Delta Mold provides the equipment, technical support and climate-controlled space needed to manufacture molds of all sizes and materials.

Talk about your setup and capabilities.

Young: We have 70,000 square feet of manufacturing floor space with 80 employees — an average tenure of 17 ½ years — and we run three shifts seven days a week. The joke is, “We can work every day except for Christmas, but we can work on Christmas for the right price.”

We’re also ISO 9001-2015 certified. We completed two audits in a row and finished the process with zero non-conformances.

We believe we’re the best-kept secret in the South because of our Charlotte location. Plus, there are not a lot of other mold shops that can do what we do. We do the easy stuff, but we’re really good at the hard stuff. We can build an injection mold of any size — as big as a boat hull to small, precision molds. For production tooling, we build anything from 50 tons up to 6,600 tons. We’ve built molds as large as 8,000 tons.

Delta Mold has in-house trial presses. The team can create samples and prototypes of all sizes and materials, as well as conduct limited production runs when needed.

We usually build about 75 new molds simultaneously; the rest is service and repair work. We do mold maintenance and repair or complete engineering changes for any mold, not just the molds we build. We have a dedicated truck, program manager, machining center and all of the necessary capabilities for any service or repair. So, if we have a customer with a mold that goes down any time of day, we can get to it within 24 hours — including getting it to our shop to fix it and then turning it around to have it back up and running. This is 15% of the business — $3 to $4 million in service, repair and engineering changes. We are constantly working to grow it.

We also do injection molding on a minimal level, so our 950- and 2,500-ton presses are dedicated to validation. Our 160-ton press runs very low-volume production for our mold-building customers, and we do some low-volume production and tryouts on our Haitian 360.

We’ve worked hard over the last five years to build molds with fewer people, which does not just mean automation. It means design strategy.

Share a snapshot of your arsenal of equipment.

Young: A tooling company is only as good as its technicians and equipment. As far as we know, we have the largest fleet of five-axis machines dedicated to mold building in our region. For example, we have a Fermat that handles up to 80,000 pounds and recently made an $850,000 investment in a TOS boring mill that can handle up to 65,000 pounds. We reinvest about $2,000,000 every other year.

Delta focuses a lot on design. Explain your design team and process.

Young: Our team has the engineering expertise to turn a proposal into a manufactured mold or part with custom design, finishing and assembly. They can develop prototypes, conduct analytical and feasibility evaluations and create full-scale designs based on an idea or operational need. What we implement into our tooling is how we help customers eliminate material and cut cycle time by 20%.

The Delta Mold engineering team, in addition to decades of experience, uses the latest 3D and CAD/CAM design software including Moldex3D, VISI, I-DEAS, WorkNC, Pro-E, Cimatron and NX.

We have five full-time designers and a manager. We’ve worked hard over the last five years to build molds with fewer people, which does not just mean automation. It means design strategy — everything from how we bring in the data to how we take that data to the mold and how we design out waste. We streamline mold design by “'doing things along the way.”'

This approach taps into our team’s experience with the various mold types we design and build. There will be an aspect of every mold project we take on that is very similar to something we’ve built before. We rarely find something that is new to us.

“I believe a mold builder must transition into a full-service company, meaning a shop has to be open to taking on more types of business than it traditionally has.”

How do you partner with customers?

Young: It’s up to us and our customers to put together the strategy to build a mold. We sit down as a team and take a systems approach to design an entire process, from the material to the final product.

For example, we designed and built a mold that produces components for a gaming station. The customer planned to sell 200,000 units a year and sold about four million! We partnered with the OEM and designed and built the press with the molding machine manufacturer — a rotational two-shot with no tie bars and a robot that runs on its own. Initially, the cycle time was 1 minute and we reduced it to 36 seconds.

Let’s talk ERP.

Young: Finding an ERP built specifically for mold building is tough. We have a robust ERP system called Plex. After a year of working with Plex, they moved some things around in their system to tailor it to us.

How did Delta Mold change during COVID-19?

Young: There’s more communication than there ever has been, both internally and with our customers. COVID also taught us a lot about the next generation. We discovered that the key to recruiting is listening and giving the teams the freedom to do their jobs. We learned how smart the next generation is and a lot of it is due to the information available to them at their fingertips.

How do you see the moldmaking industry in 5-10 years?

Young: I believe a mold builder must transition into a full-service company, meaning a shop has to be open to taking on more types of business than it traditionally has. It must be focused on the end product and not just the mold. I think Delta Mold is already there. We build all types of molds in all sizes and provide full service related to product development, equipment development, process improvement and quality improvement.

Related Content

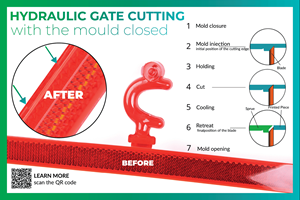

Hydraulic Gating Cutting Reliably Separates Molded Parts

NPE2024: Material displacement technology offered by Ermanno Balzi Srl enables precise separation of the molded part from the gate during the molding cycle.

Read MoreLatest Mold Analysis Software Meets Injection Molding Needs

Coretech Systems’ Moldex3D 2023 strengthens simulation performance, provides user-friendly interfaces and cloud services, streamlines workflow and strives to connect the virtual to the real.

Read MoreWhat Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

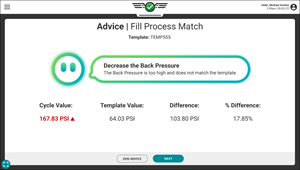

Read MoreAI Augments Injection Molding Process Control System

MAX, a new process advising feature added to RJG’s Copilot system, is engineered to help troubleshoot and optimize the injection molding process and addresses industry skill gap.

Read MoreRead Next

Cross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

Read MoreSpecialist Automotive Mold Builder Mentors in Work and Life Skills

Southeastern mold builder PFAFF Molds sets the standard in toolmaking for automotive window and vehicle body sealing systems through knowledge-sharing and automation.

Read MorePennsylvania Mold Builder Doubles Footprint, Maintains Quality and Company Values

Quality Mold Inc. doubles its manufacturing footprint but maintains its private company values and structure, delivering quality and fast turnaround from mold design and build through sampling.

Read More