Photo credit: Expand Machinery (left), Stäubli Corp. (top middle), Matsuura Machinery (top right) and Grob Systems (bottom right).

MoldMaking Technology is highlighting the latest machining, automation and EDM technologies and services being offered to the moldmaking industry. Below is a sneak-peek of some prominent companies that offer products in these categories and also appear in the November 2023 issue, including Grob Systems, EDM Network, GF Machining and more.

MMT publishs new/proven products/services on a daily basis, so browse our “New Tech” section on the homepage of our website, or find them via the website search bar. Follow each title link below for the full product post.

For a wide range of other industry-related products, make sure to check out October’s “Moldmaking-Related Technology Highlights” and “Product Innovations Pushing the Mold.”

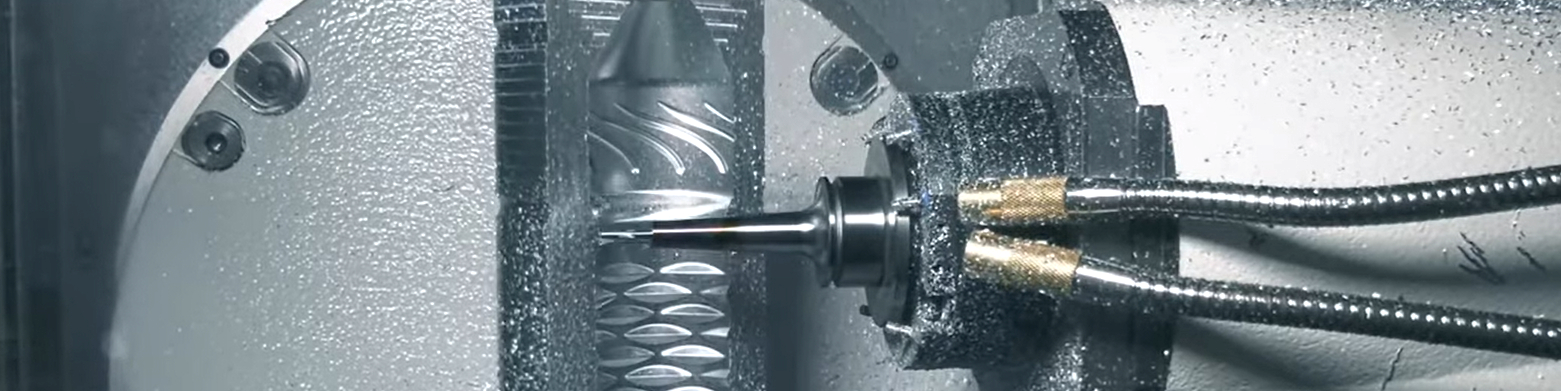

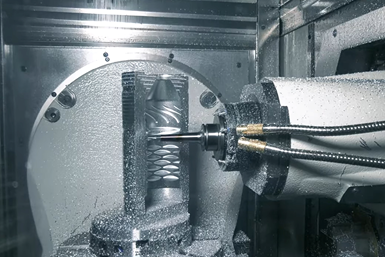

Five-Axis Machine Expands Advantages for Moldmaking

Photo credit: Expand Machinery

Five-axis machines, such as the Gen Mill 5X-24 from Expand Machinery, offer many moldmaking advantages, particularly where complex geometric cavities require a smooth and accurate surface finish, which is achieved through optimized toolpath and cutting angle control. The 5X-24’s ability to rotate and tilt the tool in multiple directions gives it access to hard-to-reach surfaces all in one setup, which increases accuracy and reduces labor and lead time for faster mold production.

Enhanced Jig Grinder Features Meet Manufacturing Flexibility Requirements

The high-performance Mitsui Seiki J350G jig grinder offers a combination of application flexibility, accuracy, reliability and operator-friendly operation, particularly for companies involved in mold or die-making where jig grinders can be used, for example, for through holes, shut-off or molding details.

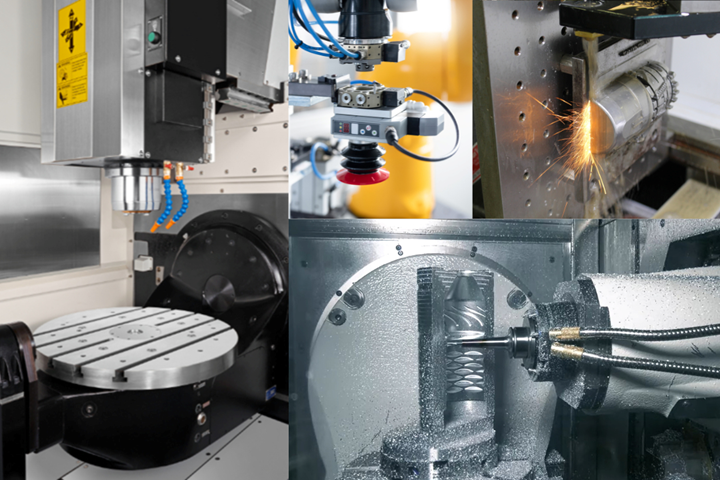

Five-Axis VMCs Attend to Versatile Machining Task Needs

Mold shops today are looking for vertical machining centers (VMCs) that can produce more faster with higher precision. YCM Technology (USA) Inc. highlights the CF/CX Series C-frame machines and RF/RX Series Ram-type machines as potential solutions. Both are available in 4+1 or five-axis high-spec configurations, which enables precision and reliability needed by moldmakers; the former machines parts up to 400 mm in diameter and the latter 650 mm in diameter.

Fast Wire EDM Targets 3D-Printed Mold Component Removal

EDM Network Inc. is now offering an economical fast wire EDM solution with the EDMMax 434W for 3D-printed metal removal on parts like the mold inserts above, printed on the Matsuura Lumex Hybrid metal 3D printer/hard mill.

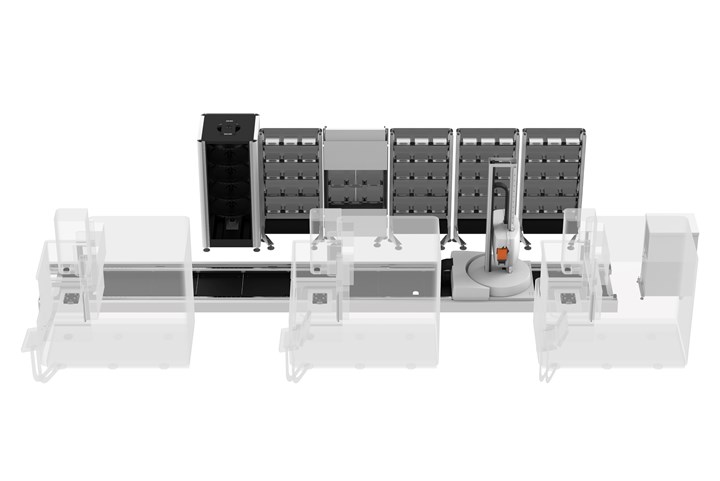

Automation System Loads up Expandability, Scalability and Precision for Moldmakers

Automation technologies, like the System 3R Transformer modular automation system from GF Machining Solutions, boost productivity, profitability and global competitiveness for moldmaking shops. It is expandable and scalable, and its adaptability and flexibility ensure that it will never be too specialized or too small to meet a facility’s future requirements.

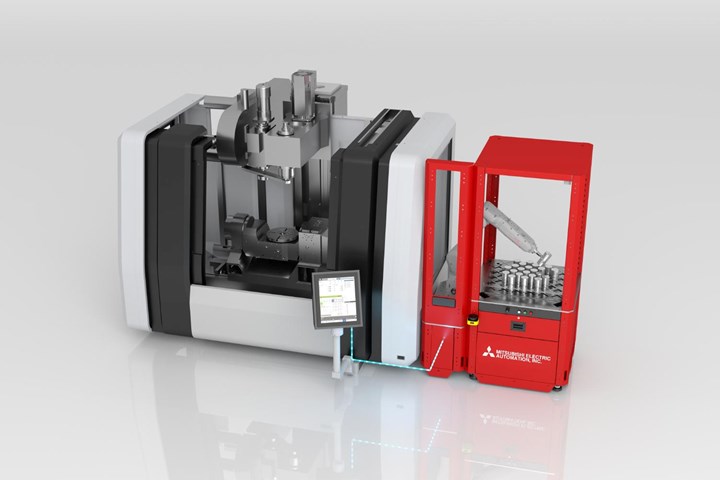

Flexibility, Maintenance Support is Made Available for Machine Tending Line

Mitsubishi Electric Automation’s LoadMate Plus machine tending line is engineered for easy setup, flexibility and mobility, while addressing labor shortage challenges and the pressure to maximize productivity. Machine tending, the process of loading and unloading parts or materials into a machine tool center, is often a key component that enable unattended or lights-out machining operations for mold manufacturers, and gives employees the opportunity to work on duties of greater value in the shop.

Related Content

How to Produce More Accurate Molds and Reduce Rework

Patented micro-milling process for manufacturing steel plate flat and parallel helps mold builders shorten mold build times and increase accuracy.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreRead Next

Do You Remember?...The Best of MMT September

Say, do you remember? These top-viewed MMT articles from September?

Read MoreWhat Do You Really Win as a Leadtime Leader?

MoldMaking Technology has honored many winners since the Leadtime Leader Awards launched in 2003, but what exactly do they win?

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)