Process Management Leads to Easier Automation

Before you move your shop into full blown automation, integrate a pallet system and process management software.

As technology has provided the means, an increasing number of moldmakers are considering par-tial or full automation of their processes. Sometimes this comes as a reaction to a shortage of available skilled labor. In other instances, automation is implemented to boost productivity and raise capacity. Additionally, some companies automate to reduce the labor cost in their parts, allowing them to remain competitive in the global market.

Whatever the driving force behind the decision to automate, the transition demands careful consideration and implementation. Those that rush in without proper preparation are likely to encounter significant setbacks and problems. By integrating automation in phases, shops can avoid these difficulties. The first and possibly most important of these phases is establishing reliable process management.

Before any actual automation is considered, a shop should evaluate its processes to ensure that they are as efficient as possible. By streamlining its operations, a moldmaker can achieve increased productivity and help guarantee a smooth integration of automation down the road. A shop can begin this evaluation by examining the flow of work in process through its facility.

Workflow Evaluation

An evaluation of workflow can easily reveal previously undetected inefficiencies. Usually, these are discovered in the area of setup times or where workpieces are being handled more than is necessary. Specifically, if a part requires work at multiple machines, setup time can become a huge loss of productivity. As the part moves through production, many manufacturers must touch off on the part every time it is transferred to a new machine. This can add a large and unnecessary amount of time to the part’s total production time and cost.

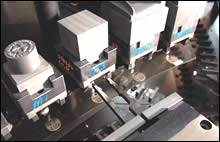

Palletization

For a relatively inexpensive solution to this problem, a shop can move into the use of pallets. Under such a system, chucks to hold the pallets are installed in all machines. This allows the part to be setup without causing machine down-time. Only one setup is necessary, as all the machines can generate offsets based off of the pallet. In addition to reducing production time, palletization also eliminates the possibility for inaccuracy that comes from setting a part up on multiple machines. For a small amount of investment, many shops can improve repeatability and reliability, while experiencing significant savings in both time and cost.

Process Management System

Once a pallet system has been implemented, even greater opportunities for efficiency become available. Quality process management software improves productivity by facilitating a smooth flow of information through the production floor. By attaching CMMs, EDMs and HSMs to the software, the sharing of information becomes instantaneous.

In an ideally configured production situation, a part begins on a pallet at a CMM. The CMM measures all necessary offsets and feeds those into the process management software. As the part moves on to be machined, these offsets are uploaded to each machine in the production cycle, saving time and eliminating the chance for error.

To further increase the benefits of such a system, ID chips can be affixed to pallets and electrodes. When a pallet is loaded onto an EDM, the software immediately identifies which series of electrodes are to be used and uploads that information to the machine. The machine can then automatically use the ID system to select the correct electrodes and commence machining.

The correct mix of pallets and process management software can clearly increase efficiency, but it also adds a flexibility that many moldmakers find useful. Should a priority job arise, the system makes it very easy to interrupt the job currently running, complete the high priority item and then resume the initial job with no significant amount of downtime or risk of inaccuracy.

Once a shop has successfully integrated a pallet system and process management software, moving into full blown automation represents a much less daunting task. As robots are added to move components through the process chain, they can be linked to the software, allowing all aspects of production to be managed from a convenient single source.

Summary

By recognizing automation is a process and not an instant solution, moldmakers can experience greater success when implementing the latest technology. Those that take the time to secure their processes and integrate the best management software will find themselves in the best position to compete within today’s global market.

Related Content

Making Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreMMT Chats: Eliminating the Noise to Stay Focused on the Customer

Metro Mold & Design joins me to discuss the value of the 80/20 rule as a business strategy, its talented cross-functional team, the role of automation in mold building and molding, and the continuing impact of COVID-19.

Read MoreQuestions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MoreDynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

Read MoreRead Next

The Center of Automation

Macro pallet-mounted gage balls reduce overall costs in electrode machining/manufacturing and reduce leadtime by 25 percent.

Read MoreInvestments in Productivity: Automation Integration In the Toolroom

By integrating machining, workpiece and cutting tool management, CMM verification, and a Web-based video and control system, a completely integrated cell producing fully qualified electrodes through automated manufacturing can be created.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More