Mold Machining

Machining (via the machine tool and cutting tool) shapes metal workpieces. Understanding both traditional and advanced machining techniques is critical to overcoming the various dimensional and finish challenges associated with mold machining. Processes include milling, drilling, grinding, high-speed machining, five-axis, hard milling, micro machining, large mold machining, multi-tasking, waterjet and laser. Workholding is also important.

ESSENTIAL READING

VIEW ALLHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreTips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreHow to Implement Five-Axis Mold Machining for Higher Productivity, Versatility

Understanding the basics of five-axis capabilities justifies the investment, but exploring all the multi-axis machine benefits and approaches enhances the return on investment.

WatchMachine Tool Considerations for Today's Mold Builder

Machine rigidity, spindle speed, power and control options that run complex programs smoothly are vital to meet the industry’s surface finish and speed requirements.

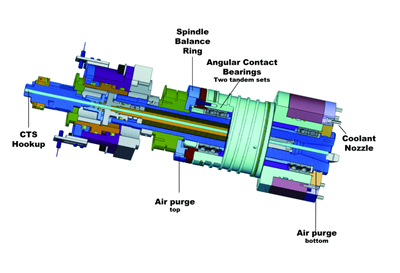

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreHow to Produce More Accurate Molds and Reduce Rework

Patented micro-milling process for manufacturing steel plate flat and parallel helps mold builders shorten mold build times and increase accuracy.

Read MoreLatest Machining News And Updates

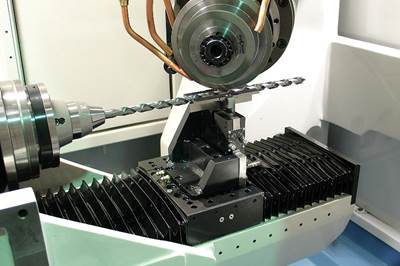

Automatic Tool Changer Benefits Machine-Adapted Clamping Units in Turning Centers

Sandvik Coromant Company introduces its automatic tool change (ATC) for machine-adapted clamping units (MACU) in turning centers.

Read MoreThree Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreFive-Axis to Complement Various Machining Capabilities

Milltronics USA Inc. highlights its latest step in the continued evolution with the release of its first true five-axis machining center, the VM250IL-5X.

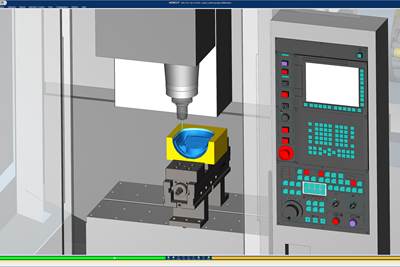

Read MoreMaximizing Machine Tool Potential With CAM Software

Identifying specific areas where CAM software can utilize machine capabilities to benefit the user and maximize milling machine potential.

Read MoreLathe Offers Affordable Access to Multi-Axis Turning

Hurco Companies Inc.’s lathe lineup, the TM8MYi was built to fill the gap between Hurco’s general purpose TM Series and high-performance TMX Series of turning centers.

Read MoreMachining Solution Enables Growth for Production Needs

GF Machining Solutions LLC highlights its Mill P 800 U S full five-axis milling machine for automation integration. According to the company, the machine enables growth as production needs increase.

Read MoreFeatured Posts

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

WatchHow to Overcome Common Deep-Hole Drilling Challenges

Producing deep holes effectively and efficiently is a challenging application that requires cutting tool solutions that offer predictable cutter life, accurate surface finish and repeatability.

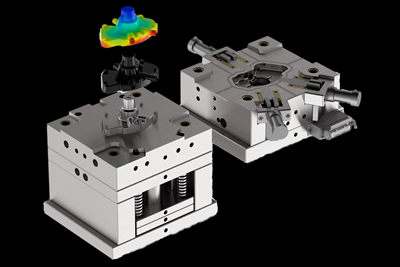

Read MoreQuick Mold Change and LSR Tooling Trends

In this short but informational MMT Chat, MMT Editorial Director, Christina Fuges, sits down with Roembke Mfg. & Design Inc.’s Business Development Manager, Adam Shaal, to talk about a quick mold change solution, LSR tooling and the future moldmaker.

WatchTechnology Review and Sourcing Guide 2024: Machining

Understanding both traditional and advanced machining techniques is vital to overcoming various dimensional and finish challenges associated with mold machining. Access more information about machining in this exclusive, online-only content, including a suppliers list, machining products and more.

Read MoreQuality Tool & Die Enhances Performance With Advanced EDM and Milling Technologies

The adoption of Mitsubishi wire and sinker EDMs, along with the OPS Ingersoll five-axis milling machine with automated cells, has enabled unmanned operations and improved precision. As a result, QTD has expanded its facility, grown its workforce and increased its business by 10-15% annually.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreFAQ: Machining

What should a moldmaker look for in a CNC control?

A CNC control should have features to automatically smooth the axis movements or allow the operator to set tolerance limits manually.

- Spatial plane function: Many mold cores or bases require five-sided machining without excessive coordinated movements. The CNC should have a spatial plane function that allows the machinist to set the plane that is machined on each side of the part. That way, the machinist can program each side of the part in an X-Y-Z plane without changing the CAM program and ultimately improve the tolerances between features on each side.

- Contour deviation monitoring: The control directs axis movements to follow the 3D surfaces within predefined tolerance bands that consist of simple line segments. The control should automatically smooth the block transitions while the tool moves continuously on the workpiece surface. An internal function that monitors the contour deviations controls automatic smoothing, enabling the user to define the maximum-allowed contour deviation. The machine tool builder determines the default value in a machine parameter of the control (typically 0.01 to 0.02 millimeter). The tolerance also affects the traverse paths on programmed circular motions, which is important if the core or cavity has cylindrical details that a user machines with either an interpolation milling or a mill-turn function.

- Linear encoder compatibility: The CNC control should ensure that all machine axes follow the exact path when moving from X-plus to X-minus and then moving from X-minus to X-plus after a stepover. There must be an exact reproduction of adjacent paths after cutting direction reversal.

- Vibration mitigation: A machine axis moving very fast and changing direction on a point or using a higher-than-permitted feed rate for the cutting tool can generate vibration, impacting part quality. The CNC control should monitor any tool vibration caused by either high dynamic movements or higher-than-permitted feed rates, and then adjust feeds and speeds to avoid chatter marks on the final part.

- Operator flexibility: The CNC interface should optimize the machine dynamics based on each part’s feature priorities. The control should allow the operator or programmer to verify and optimize the program on the fly. For example, several different components made on the same machine, each with different accuracy, surface finish and lead time requirements.

- Automatic feed and speed adjustments: Milling through mold cores or cavities with variable workpiece thicknesses is another machining challenge. A solution is a CNC that can detect how much material is currently cut, so the feeds and speeds can be automatically adjusted without operator intervention. This is accomplished with sensors connected to the CNC that measure spindle load and vibration and then identify and adjust speeds and feeds within milliseconds. This technology ensures that the machine maximizes chip removal rate based on workpiece cutting tool engagement, as well as cutter and spindle life.

What should a shop consider before deciding to upgrade machine tool technology?

Justifying new technology is a multi-step process that requires a thorough assessment of a number of factors at work in your manufacturing operation.

- 1. Understand your costs

- Use a transparent costing system

- Evaluate all cost factors

- Evaluate the influence of new technology on the cash flow

- Calculate production cost and evaluate the influence of investment of new technology on production cost and return on investment

- Understand potential benefits of CNC technology; measurable benefits

- Productivity

- Reduced setup and tool change time

- Improved uptime

- Throughput

- Scrap rate

- Tooling cost

- Maintenance cost

- Job preparation cost

There are also intangible benefits that may not be calculable, but can have a major effect on your machining success—including quality, accuracy and surface finish, which should not depend on operator skill and should not require constant checking; and, preset quick change tooling with standardized inserts that save production time (up to 15 percent or more compared to setting the tools on the machine so the machine is productive for a greater part of the shift).

- Understand the costs of older equipment

- • Lower efficiencies

- • Longer than planned setup times

- • Requires vanishing skills to set up and operate

-

• Requires tweaking to successfully run good parts—only a few setup/operators in your company have this ability

• Incapable of today’s quality requirements

• Cannot statistically hold tolerances

• Produces excessive scrap parts, hurting efficiency, adding to material cost

• Frequent unplanned downtime for repairs

• In-house maintenance personnel (overhead) - Source: How to Justify New Machine Tool Technology

Why do moldmakers need a tool presetter?

Shops can reduce idle time using tool presetters. High-quality tool presetters enable shops to take fast, accurate and repeatable measurements for each tool offline. This capability makes it possible for machinists to set tools while the machine is still running, which reduces idle time and increases cost efficiency in the shop. In addition to time and accuracy, the nature of presetting inherently promotes greater emphasis on best practices on ideal ways to store and measure tools. Toolboxes and drawers with random tooling ultimately migrate to more centralized tool-management areas.

The important attributes of a presetter are:

- Accuracy. In the era of Industry 4.0, presetters should be able to maintain repeatable measuring accuracy of 5 microns or better. This usually means that the system should be equipped with an optical measuring device, which is more accurate than physical contact (or indicator) devices.

- Repeatability. It is not just a function of measuring accuracy, but also of thermal stability. Presetters that use multiple material types in their base construction are more prone to non-uniform thermal expansion in the shop environment, which can require daily, repeated calibrations to output repeatable measurements.

- Capacity. Before making a purchase, shops should consider the size and weight of their largest tooling assembly. Here is where size matters, so shops want to be sure the machine can handle the maximum weight, height and diameter of the tools they need to measure.

- Ease of use. Adoption rates in the shop are key. The machine with the greatest capability in the world will end up being one of the largest paperweights in the world if no one can figure out and remember how to use it. When looking at functionality, examine the usability of the software, how many options and screens one has to look at to measure basic dimensions, and the overall ergonomics of the machine.

Source: Why You Need a Tool Presetter

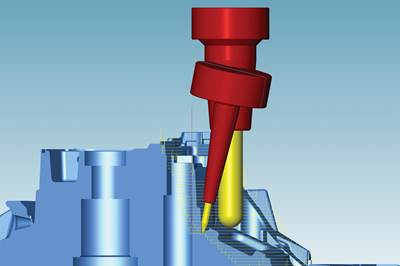

What are the benefits of five-axis machining?

With careful consideration given to the specific application and the various alternate means of achieving five-axis capabilities, there are a large number of benefits that five-axis machining can bring to the moldmaker.

By using a flat bottom end mill and maintaining perpendicularity to the complex surface, machining time can be greatly reduced. This is accomplished by stepping over the full diameter of the cutter, which reduces the required number of passes across a surface. The same principle applies to side milling of angled surfaces. This same process will also eliminate ribbing caused by ball-nose end mills, resulting in a much better surface finish, and cut down on manual millwork and handwork required to clean up kellered surfaces.

Five-axis technology also eliminates multiple setups required to re-position the workpiece at complex angles. This not only saves time, but greatly reduces errors and costly tooling and fixture expenses required to hold the workpiece in place. It also provides the ability to machine complex parts that are not otherwise possible—including holes, pockets and tapping required to be normal to a complex surface.

Through the use of shorter tools, five-axis milling can complete an entire part without re-fixturing or using the long tools required in a similar three-axis application and still deliver the final product in less time and with a better surface finish. Because the cutter extends out from the pivot point, a spindle-based attachment can actually mill outside the host machine’s stated travels when working inside a mold cavity.

Source: Five-Axis Machining: What Are The Benefits and How Can You Achieve this Capability?

.jpg;maxWidth=970;quality=90)