Automation Advancements Streamline Mold Manufacturing

Implementing new technologies across the entire shop floor improves overall accuracy, productivity and profitability.

Automation can be defined by mold manufacturers on many levels; however, the results—efficiency, productivity and accuracy—can probably be agreed upon by all. Implementing automation technology on the shop floor through cell manager software, combined CAD/CAM systems, robots and machines with in-process inspection will allow the mold manufacturing process to be completed as quickly and efficiently as possible—perhaps with less manpower.

A group of automation technology suppliers discuss the questions they most often get asked as well as how the latest advancements can streamline the entire mold manufacturing process.

Automation Inquiries

Since automation is a matter of being as efficient and productive as possible in the shortest timeframe, most questions automation technology suppliers handle have to do with improving efficiencies. Andre Ey, Vice President of Makino Die Mold & EDM Technologies, notes the most common question the company is asked by mold manufacturers is how they can be more effective in their shops. “Smaller shops are looking at how they can get the most out of their current manpower without adding additional shifts,” Ey elaborates. “Many of these manufacturers are evaluating automated capabilities and the impact they will have on their shop environment. They’re looking at how to get more production hours for both competitiveness and profitability.

“Many larger shops are already implementing automated capabilities, but are researching how they can monitor their overall throughput more effectively to identify bottlenecks and opportunities for improvement,” Ey continues. “These monitoring capabilities look beyond the automated system—evaluating overall manufacturing efficiency from the moment of raw material arrival to finished part delivery.”

Moldmakers often seek advice as to how they can easily and cost effectively implement automation into their operations, especially with skilled labor at a premium these days, notes Gisbert Ledvon, Business Development Manager, GFAgie Charmilles (Lincolnshire, IL). “With machine tool technology becoming more advanced, yet less complicated to use, they want to know how the latest automation solutions can streamline their efforts and improve their overall accuracy, productivity and profitability,” he states. “In fact, wanting to keep as many processes in-house as possible, moldmakers frequently ask us about highly integrated solutions that enable them to seamlessly move their mold insert from one machining process to the next—such as five-axis milling to wire EDM to hole drilling to laser texturing—without having to pick up the part or re-program cavity locations.”

According to John Roskos, Vice President Sales, System 3R, USA LLC. (Elk Grove Village, IL), the questions the company fields regarding automation center around how a mold manufacturer can get started in automation, in what department is an automation investment most productive, what process is easiest to automate and what kind of learning curve can be expected.

On the software end, Bryan Jacobs, Marketing Communications Manager, CG Tech (Irvine, CA), says that questions the company receives involve fundamental parts of the manufacturing process, related to part accuracy, scrap reduction, machine collisions and even operator involvement. “A common question is, ‘How can I ensure the mold will be correct the first time it is machined, while also reducing the number of set-ups required?’”

Companies have also increasingly asked for a way to make a virtual CNC simulation available to staff on the factory floor, Jacobs continues. “It is not really a new idea, and one that seems like a logical and useful application of simulation, but it has been minimally adopted. Whether that’s due to hardware costs, software costs, complexity, reliability or other factors is not really clear, but it’s likely a combination of factors. There are several shops using CNC animations on the factory floor, but not the majority. We offer a product that allows a low-end computer to interactively replay a simulation using a stand-alone unlicensed player. The user can dynamically rotate/pan/zoom the animated image, as well as measure features and inspect NC program lines.”

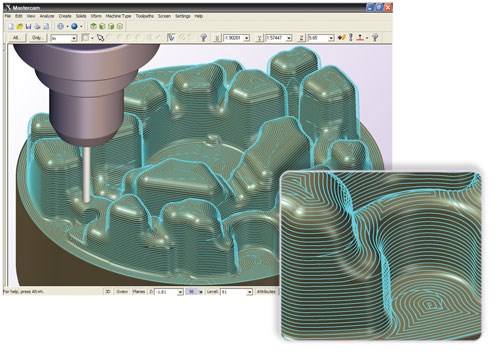

Also on the software end, Ben Mund, Marketing Manager and Steve Bertrand, Corporate Sales Manager, Mastercam/CNC Software, Inc. (Tolland, CT) add that Mastercam addresses automation questions concerning price. “We often get asked how mold shops can maintain precision, but produce parts quicker so they can compete on price,” Mund says. “There are several ways to address this. One is through software alone, such as hybrid toolpaths that combine cutting motions into a single toolpath—resulting in better finish and more efficient use of the tool. Another is combination approaches where software and tooling work hand-in-hand.

With regards to competing with prices from foreign markets while reducing the total burden cost of manufacturing a mold, Bertrand suggest that mold manufacturers start with the technology they already have. “Dig down into your software and find features and enhancements that you are not currently using, and use them!” he urges. “You would be surprised at the number of people who are not using their software to its fullest potential. Take advantage of your machine’s technology as well. Many software packages are now pairing up with cutting tool manufacturers to provide tooling inserts that work specifically with software toolpaths.

Technology Advancements

Machine tool controls with higher functionality, advances in CAD/CAM software streamlining the programming process, modular and flexible automation systems, and implementation and acceptance of cell manager software systems are all trends identified by Roskos of System 3R.

Ledvon of GFAgie Charmilles believes that with more moldmakers embracing automation more than ever before, machine tool builders will continue to develop new highly intuitive ways in which their customers can perform production runs with as little labor involvement as possible. “What seems to be happening now is that machine tool manufacturers are creating automation levels—from basic to advanced—making it possible for their customers to ease into automation via a step-by-step approach.”

A mold manufacturer can start off basic with a pallet changer that integrates with the machine’s control and toolchanger, enabling operators to select electrodes and identify workpieces with very little training required, Ledvon maintains. “The same goes for the machine’s software where a very structured, interactive menu-driven programming process minimizes the possibilities of error during machine setup, allowing operators to control the CNC machines with confidence,” he notes.

Once the mold manufacturer masters the basic automation, they can transition into more advanced automation solutions involving robots and manufacturing cell software, such as a management system that controls the data linked to production orders, Ledvon adds. “For example, the operator can program a robot to feed multiple machines for unmanned, automatic job machining, while also utilizing cell software to control the management of the data, workpieces and tools connected with open production orders,” he states.

Furthermore, Ledvon points out that machines with in-process inspection functionality will be in higher demand because moldmakers can measure the accuracy of their parts before they ever leave the machine. By focusing on the inspection of a workpiece throughout the machining process rather than at the end, moldmakers can improve upon their delivery times and overall part quality, he adds.

Better communication between automated machining technology and factory systems is key, Makino’s Ey says. “The concept of automation should be a holistic approach that applies to the entire shop floor,” he emphasizes. “As such, one must look at their overall process to determine what needs to be achieved and ask himself whether or not his current factory system can handle the additional capacity.

“By adding efficiency through automated machining technologies, bottlenecks are inherently created elsewhere in the manufacturing process,” Ey continues. “As such, manufacturers are constantly chasing bottlenecks. For example, if you add an automation system to your shop floor, you’re going to see improved productivity from your machines; however, this higher volume leaving the cell may create a bottleneck in the assembly process. From start to finish, managing the flow of your business requires communication software to help identify bottlenecks and opportunities for improvement throughout the factory system.”

Efficiency on the software end is combining CAD/CAM packages, Mastercam’s Mund says, which allows mold manufacturers to work inside a single interface of software, and a single database will house all the part information. “No longer will they have to learn a CAD package, and then learn a CAM package. They will no longer have trouble bringing in files.”

Jacobs of CGTech believes there are many different levels of automation. “We see automation as something that helps machines run unattended,” Jacobs says. “Most agree on several key benefits: increased productivity, reduced scrap loss, improved scheduling, less waiting, added shifts without adding staff, even the ability to take advantage of off-peak power consumption.

“To be more specific, we have seen a much heavier utilization of on-machine probing,” he continues. “Probing, however, also means different things to different people. We first started seeing probing to verify that the set-ups are correct. The probe may touch the pallet to make sure that the set-up matches the NC program that is about to run. The use of probing has been extended to inspect part features throughout the machining process to ensure the NC programs and tooling are doing what they are supposed to be doing.”

CG Tech also is seeing an increase in the use of robots. “In response, CNC simulation software now simulates six-axis articulated-arm robot motion from leading robot machine builders,” he comments. “It also supports robots that have additional ‘external’ axes. For example, robots mounted on a linear axis (or a part on a rotisserie axis) can significantly improve robot usefulness, reach, stiffness, speed and accuracy.”

Other automation features that can help moldmakers include remote monitoring systems and electronic notification systems, Jacobs adds. “These systems give the moldmaker real-time feedback with the ability to log in and see which machines are working or waiting, and can even send an alarm when necessary. Some also have surveillance cameras installed in them to make sure everything looks as it did during the simulation step.”

What’s New

Automation suppliers have been working hard to provide the latest in automation technology for the mold manufacturing industry. Bertrand of Mastercam says that its Mastercam for SolidWorks product is constantly being worked on and added to. “For instance, we just came out with multiaxis functionality with the X6 release of Mastercam, and the X7 release will feature lathe,” he says. “We are constantly improving the Mastercam for SolidWorks products for our customers to make their designing work and machining work easier and faster than ever before.

“New hybrid machining provides better surface machining, which yields a better surface finish and less secondary work is required,” he continues. “Toolpaths are constantly being refined and new ones are being designed to improve customer interaction with the software. This results in faster machining, better toolpaths, getting parts off the machine faster, and a better ROI for their shop.”

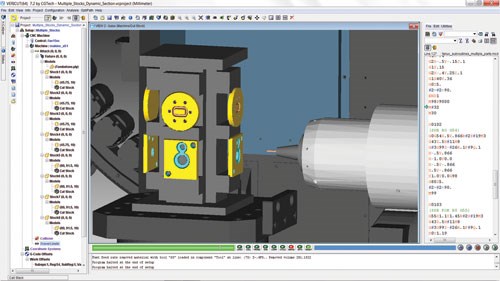

At CGTech, the company is ramping up its simulation software. “Machines used in conjunction with automation equipment tend to be more complex,” Jacobs comments. “They are faster and more expensive and include a variety of attachments. Simulation software has to handle all of it. Robots, pallet changers, part loaders and movers can all be modeled up and simulated Confidence is created when the moldmaker can simulate every part of the process.

“As more VERICUT CNC simulation software features are added to support these new technologies, added complexity is inevitable,” Jacobs continues. “VERICUT’s design is regularly reviewed and refreshed, focusing on how customers use VERICUT and how it can better fit a modern manufacturing environment. In the latest release, VERICUT's user interface has a more natural sequence to common user actions. Utilizing a top-down flow through a graphical tree layout, context sensitive choices appear as the user moves along the NC program simulation process. As a result, setting up a new project and running a VERICUT simulation is very simple. For example, many moldmakers gang multiple stocks on a tombstone. The new version of VERICUT makes it simpler to work with multiple stocks, and even reduces the system requirements.”

Makino has entered into the software market as well. Makino provides both the technologies and services to automate a die/mold manufacturing system, and is continually enhancing software interfaces to communicate with other machines and external software, Ey notes. “We have developed proprietary software called MPmax (Machine Productivity Maximizer) that monitors and reports the effectiveness of all Makino machines on a customer’s shop floor. Our machines are compatible with most third-party systems, including robotic technologies and scheduling software. With decades of automation integration experience, Makino provides the technologies, software and services to ensure the smoothest possible installation of multi-vendor projects.”

GFAgie Charmilles is also on the case “Never a company to rest on its laurels, we are continuously looking at new ways in which we can make automation even more intuitive for our moldmaking customers,” Ledvon affirms. The company’s latest automation solutions manage complete manufacturing process flows, from preparation to machining. This includes programming (CAD/CAM level), management of the workshop, traceability and handling.

Additionally, System 3R offers WorkShopManager Software, which Roskos says continues to shrink the learning curves and push the functionality of new and existing automation cells. “System 3R continues to develop new solutions to help the modern moldmaker achieve higher rates of productivity,” he states. “The development of our new WorkPartner 1+ adds great capacity in a small package—allowing two machines to be automated in a very small floor space. Our design team is constantly stretching the boundaries of magazine and gripper design to support new applications and new machine tools; and our linear automation system is raising the level of productivity at mold shops around the world by expanding the limits of what can be included in an automation cell.”

Get Started

Cleary, implanting automation on the shop floor has a myriad of benefits. Start off slowly by carefully examining your entire process. Implement—and master—the aforementioned basics first, then transition to more advanced solutions. Suppliers are ready and willing to answer questions and work on the best systems and solutions for your needs. Makino’s Ey concludes, “At the end of the day, all moldmakers want to know how they can gain more throughput, reduce leadtimes and improve the general workflow in their facilities.”

Related Content

Mold Builder Meets Increased Domestic Demand With Automated Cells

Burteck LLC experienced significant demand increases due to reshoring and invested in automated machining cells to step up its production output quickly and avoid losing business.

Read MoreTool Paths, ERP & Improving Efficiency in Your Toolroom: What Did You Miss in February?

We covered a variety of topics in February. From tool paths to ERP and PTXPO coverage, we hope you didn’t miss anything but here is your cheat sheet if you did.

Read MoreTechnology Roundup: New/Improved Technologies You Don't Want to Miss

With all the technology joining the market, moldmaking is a versatile, ever-evolving industry. As such, this technology roundup has no specific theme — it features a variety of products for applications and solutions across the industry.

Read MoreFive-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

Read MoreRead Next

Standardize Before You Automate

After standardization, automation will create the largest increase in profits that any one area can produce.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)