Latest Maintain News And Updates

Quality Verification of Machine-Ready Blanks With New CMM

TCI Precision Metals highlights the installation of the newest Keyence model XM-5000 handheld probe coordinate measuring machine (CMM).

Read More2024 Moldmaking Insights: A Year in Review Part 2

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

Read More2024 Moldmaking Insights: A Year in Review Part 1

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

Read MoreMoldMaking Technology's Most-Viewed Content of 2024

The most popular MoldMaking Technology content according to analytics reports over the past year.

Read MoreLine Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreFeatured Posts

How to Achieve Automated Measurement With Advanced Touch Probes and Laser Systems

A combination of lasers, probes and software help moldmakers automate in-process cutting tool and workpiece measurement.

Read MoreHow to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreLaser Welder Yields Fast, Precise Mold Repair

Intralox's integration of the Alpha Laser ALFlak has significantly improved their tool room efficiency when it comes to difficult welds and urgent repairs.

Read MoreBest Practices for Engraving Cores and Cavities

Consider depth, font style, artwork size, polarity and location when engraving.

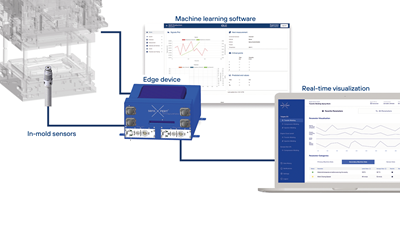

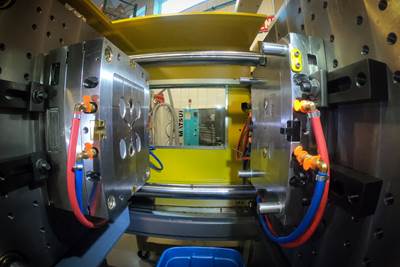

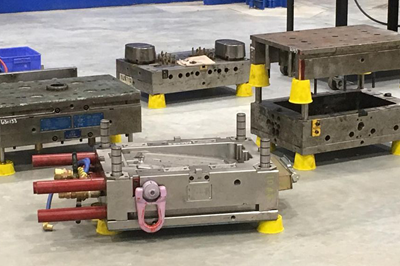

Read MoreHow to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

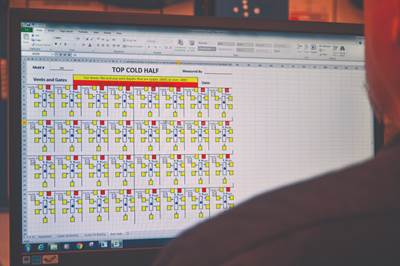

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read More