Golf is a game that is played on a five-inch course — the distance between your ears.” Moldmakers can apply that same “measurable” distance to their moldmaking business. Source | Getty Images

Mold manufacturing requires using measurement to a shop’s advantage because what gets measured, gets done. I’ve played golf with players who want to improve their game, and the one thing I noticed is that they keep track of their shots in one form or another (fairways hit, greens in regulation and putts). You might be asking, “Who am I to be tracking my stats? I’m just an average player.” Well, average players can become good players, and good players can become exceptional players. You must introduce objective analysis to see areas where you can improve your performance, so you can maximize your practice sessions and work on those things that are causing the most grief in your game. Sometimes it is just easier to keep things vague and fuzzy, but if that impedes the results you are looking for, then it might be time to introduce some type of measurement to improve your game.

This is nothing new. If you’ve watched the Olympics, for example, you witnessed some of the most finely-tuned athletes in the world compete in events where hundredths of a second count. These are some of the most measured athletes on the planet. From their caloric intake to their workout repetitions and training schedules, they are measured in supreme detail because they know it produces results. It makes them better than the competition.

Take some time to look at the stats a current PGA professional tracks on a regular basis. It includes strokes gained in putting, scrambling, sand saves, launch angle, swing speed, and much more. It is all about developing consistency and measurements. If the PGA (Professional Golf Association) players track their stats to improve their performance and ultimately make more money, what stats do the PMA (Professional Moldbuilders Association) members track in their competitive arena?

“Tracking and measuring the types and quantities of the mix can help a shop establish a profitability probability equation, which they can ultimately turn into a key performance indicator for the entire business team.”

Identify Your Stats

Mold builders must measure to identify areas where the business can improve performance, putting the shop at the tops of its game. Source | iStock

The first question is: Do you consider your company to be a tool shop or a high-tech business? Today’s modern, growth-oriented businesses have stats to measure their success. So, how can you bring measurement into your mold-building business to achieve specific results? Consider these aspects as possible starting points:

- How do you know what your biggest moneymaking area is, and how do you capture and measure that?

- How do you measure your profit margin?

Since quoting is predicated on hours, ask yourself these questions:

- How do you cost an hour? What is the “true” cost of an hour?

- How do you measure your break-even point?

- How do you measure direct versus indirect hours?

When using automation, consider these questions:

- How do you capture (measure) and cost unattended hours?

- How do you know what new automated equipment to purchase? (What measurements would you take?)

- What are the measurements of the type of work you do that will help you buy technology and enhance profitability?

This does not have to be complicated! Let’s go back to analyzing our golf game to establish the process. Ask yourself: How can we bring measurement into our golf game to achieve specific results? First, decide on a specific and precise result. Perhaps you want to hit more fairways off the tee. Historical/statistical analysis shows that you are hitting about 40 percent of fairways and you want to achieve a consistent rate of 60 percent. Now you have a goal to work with, so it is time to introduce measurement to get precise results. Step one might be to make an appointment with a golf instructor to have him/her diagnose just what is happening to produce so many non-solid and off-center hits.

Next, you would need to set up a schedule. For example, practice for 45 minutes on Tuesday, Thursday and Saturday to work on that specific swing flaw, and nothing else. That makes your practice session very clear and focused. Then head to the course, drop some balls and experiment a little. Try different lofts, grips types (strong left hand, weak left hand and neutral), and maybe even different driver manufacturers. Then record any insights or observations after the session and note when the next session is. Notes can include successful shots, unsuccessful shots, conditions, and surprises. When you measure, you can adjust. It is very easy to look at and adjust your activity based on your results.

“The key to establishing measurables is keeping and incorporating historical data into the process, which makes a post-project review critical.”

Measure and Track

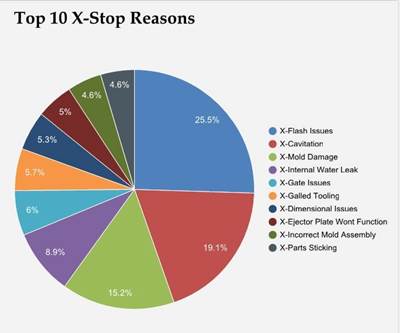

Now let’s look at the business and use the same process. Set the goal of finding the biggest money-making area of the business with the specific and precise result of finding the area that has the largest profit margin. First, identify the types of projects or the mix of work that makes up the business (see chart).

Review and analyze the profit margin historical data in each project category. Then establish a targeted profit margin for each, thereby establishing a measurable. What area brings in the greatest profit margin? You can even break down the type of new molds into a sub-category to be even more precise. For example, two-plate molds, molds with side actions, unscrewing molds, etc. Then calculate the best profit margin on new molds.

The key to establishing measurables is keeping and incorporating historical data into the process, which makes a post-project review critical. This review establishes the mathematical numbers that will become usable data for statistical analysis and continuous improvement. Now you have worked hard on each project and have created valuable information for your business. Do not waste this opportunity to use the beauty of mathematics. Quoting Albert Einstein: “Pure mathematics is, in its way, the poetry of logical ideas.”

With this new information in your toolbox, the sales team can pursue more of one type of business or more of one type of mold to establish a more profitable mix. Tracking and measuring the types and quantities of the mix can help a shop establish a profitability probability equation, which they can ultimately turn into a KPI (Key Performance Indicator) for the entire business team.

Once the team has compiled all of the data, they should set up quoting templates to represent the statistical data for each category and type of mold, making this a more predictable process. The numbers do not lie. I have found over the years that introducing performance metrics can relieve pressure because you defined “very specifically” your result. Then all you have to do is follow the recipe to produce the result. It makes life (and your progress) easier.

“The first question is: Do you consider your company to be a tool shop or a high-tech business? Today’s modern, growth-oriented businesses have stats to measure their success. So, how can you bring measurement into your mold-building business to achieve specific results?"

Get Started

To begin, use the questions listed or create your own, but the process should be the same. In the end, if you did not come close to your goal, find another path that gets better results. Keep testing until the formula works.

Moldmakers can find the area of the business that has the largest profit margin by first identifying the types of projects or the mix of work that makes up the business. Source | Don Smith

The reality is that the next generation coming into our industry is into analytics and numbers. They crave that immediate gratification that the numbers will provide. They may even create an app for the business. These numbers will motivate and drive young men and women to create the future of our industry. Getting back to golf, World Golf Hall of Famer and Masters Tournament co-founder Bobby Jones said, “Golf is a game that is played on a five-inch course--the distance between your ears.” By the way, moldmakers can apply that same “measurable” distance to their moldmaking businesses.

Related Content

What is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

Read MoreWhat Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreMMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.

Read MoreTake Time to Save Time: 6 Steps in Mold Design to Reduce Back-End Troubleshooting

Westminster Tool shares how the one week it typically takes to perform these six steps in the design phase can save three weeks or more in an overall tool build.

Read MoreRead Next

Tooling 4.0: Connecting Industry 4.0 Technology to Your Molds and Molding Process

A packaging supplier applies Industry 4.0 technology to its injection molds so that components talk to each another to understand the dynamics of what is happening inside the mold.

Read MoreHow Will Industry 4.0 Impact Mold Maintenance?

Many toolrooms want to replace manual entries with electronic data when creating maintenance work orders and providing past historical issues, corrective actions and the effectiveness level of resolutions, but technicians require more information than electronic signals can provide to prove a return on investment of their time.

Read MoreHow a Mold Builder Can Implement Industry 4.0

Properly planning the implementation of an Industry 4.0 system will yield short lead times, an improved bottom line and a more efficient shop floor.

Read More