Teams collaborate during design review meetings using mold simulation, DFM and processing expertise to ensure well-managed, timely project execution tailored to scope. Source (All Images) | Dynamic Tool Corp.

For moldmakers, new product development (NPD) projects represent both exciting opportunities and potential pitfalls. These projects offer the chance to work on cutting-edge designs for globally recognized brands, but they also come with unique challenges that can strain customer relationships and project timelines.

In the moldmaking world, NPD isn't limited to entirely new products. It can also encompass significant redesigns of existing products. For moldmakers, this means working with initial product designs not vetted for manufacturability and multiple design revisions and requotes to produce parts with unexplored geometries or features.

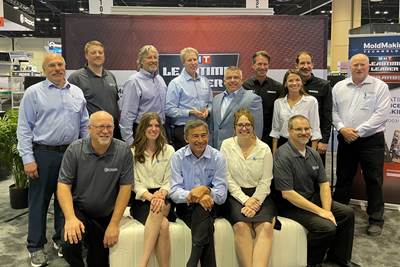

John Berg, New Business Development Manager for Dynamic Tool Corporation – and MoldMaking Technology’s 2024 Leadtime Leader winner – says, “NPD for the tool shop is designing and building an injection mold that's never been designed or built before to create a part that's never been manufactured before. It's pretty exciting, but it requires great discipline.”

The challenges, which can be numerous and need to be balanced, include:

- Navigating complex part geometries as wanted or needed

- Implementing novel design features and the ability to maintain them

- Addressing impacts on steel conditions, actions and weight risks to up time

- Developing appropriate ejection and thermal control systems as well as all elements for robust production

- Creating specialized surface finishes and coatings to optimize the performance of emerging material streams

For multi-shot or in-mold decorating projects, additional hurdles may include material bonding, flash control and label placement issues.

“NPD for the tool shop is designing and building an injection mold that's never been designed or built before to create a part that's never been manufactured before. It's pretty exciting, but it requires great discipline.”

Communication

One of the most crucial aspects of managing NPD projects is maintaining clear, consistent communication with the customer. This communication needs to go beyond technical details and consider the broader context of the project.

Effective communication helps maintain positive project momentum and prevents misunderstandings that can damage customer relationships. It's essential to prepare customer contacts to translate technical challenges into language that executive-level decision-makers can easily understand.

Experts in design, moldmaking and production solve customer challenges during tool build review meeting.

Project Management

Bill Mentzer in Development at DTC, drawing from his extensive experience, outlines several best practices for successfully navigating NPD projects, “At the end of the day, best practices are best practices for a reason. It’s about defining what you know and why you know it, what you think you know and why you think you know it - but should confirm. And finally, what don’t you know, but need to find out,” Mentzer.

1. Define the Project Scope

Before diving into design and production, it's critical to establish a clear project scope. This includes defining buy-in, acceptance criteria, resource planning, scheduling and cost modeling.

2. Assess Knowledge and Unknowns

A thorough evaluation of what is known, what is believed to be known and what remains unknown about the project helps identify potential risks and areas requiring further investigation.

3. Guard Against Scope Creep

NPD projects are particularly susceptible to scope creep. Changes like switching to high-gloss finishes or altering material handling requirements can significantly impact costs and timelines. Identifying these factors early is crucial for maintaining project viability.

4. Leverage Simulation and Virtual Prototyping

While not a substitute for physical testing, simulation and virtual prototyping tools can provide valuable insights early in the development process. Proper gate design, in particular, can solve a majority of potential issues.

5. Treat Prints as Living Documents

Tolerances specified in initial prints may not always align with manufacturing capabilities or actual product requirements. Robust product testing can help refine print specifications based on real-world manufacturing capabilities.

6. Embrace Thorough Process Development and Validation

Although often viewed as time-consuming and expensive, thorough process development and validation are critical for long-term project success. These steps help identify the key factors controlling product quality and enable faster troubleshooting when issues arise.

Balancing Prototyping Methods with Production Intent

A key challenge in NPD projects is focusing on the ultimate production intent while progressing through various prototyping stages. It's crucial to keep the customer's engineering team focused on the end goal, particularly for high-volume production scenarios.

Berg emphasizes, “We always do our very best to keep the customers' engineering team focused on what we'll call the production intent design. Because it's very tempting to feel that you've accomplished something if you're going through the formative stages of prototyping or virtual prototyping. But, we have to remember the end goal.”

While early prototyping methods like 3D printing can provide quick results, they cannot address critical factors for high-volume production like a pilot or bridge mold, such as cooling systems, optimal gate locations or material handling characteristics. Moldmakers must guide customers through the prototyping process with the final production requirements in mind.

The in-house sampling team ensures productivity with scientific molding services, from functional samples to full protocols for precise production.

The Value of Mold Validation

Despite being often viewed as a tedious and expensive process, mold validation plays a crucial role in ensuring long-term project success. Thorough validation helps identify the key factors controlling product quality and enables rapid troubleshooting when issues arise during production.

Mentzer notes, “Validation is your opportunity to learn what really controls the quality of your product, get your hands around it, measure the right thing at high volume, low cost. If you don't, then you're chasing what happened, as opposed to saying I need to figure out what changed.”

“It's really about defining what you know and why you know it, what you think you know and why you think you know it, and what you don't know but really need to find out.”

Managing Customer Expectations and Costs

A recurring theme in NPD projects is managing customer expectations, particularly regarding costs. The OEM ultimately owns the cost of their part, driven by factors like material choice, part thickness and design features.

Moldmakers must clearly communicate how design decisions impact costs and production capabilities. This transparency helps prevent misunderstandings and allows for more realistic project planning.

The Long Game of NPD Projects

OEMs often have multiple NPD projects running concurrently, with only a small percentage reaching full production. For moldmakers, this means each NPD project is an opportunity to demonstrate value, build customer relationships and position themselves for future business.

As projects progress from prototype to production, there may be opportunities for bridge tooling or incremental capacity increases. These steps allow for further refinement of the tooling system and can lead to additional business opportunities.

Successful navigation of new product development projects in moldmaking requires a delicate balance of technical expertise, clear communication, and strategic thinking. By embracing best practices, maintaining a focus on production intent and effectively managing customer expectations, moldmakers can turn the challenges of NPD into opportunities for growth and long-term success. The key lies in viewing each project not as a single mold build, but as part of an ongoing partnership with the customer, aimed at bringing innovative products to market efficiently.

Related Content

FAQs: What Are the Leadtime Leader Awards?

Here are answers to some frequently asked questions about MoldMaking Technology's annual Leadtime Leader Awards competition.

Read MoreMoldMaking Technology's Most-Viewed Content of 2024

The most popular MoldMaking Technology content according to analytics reports over the past year.

Read MoreMMT's Most-Viewed March Content: Digitalization in Tooling, The Leadtime Leader Awards & More

March was a big month for MoldMaking Technology. Not only did we celebrate our 25th Anniversary, PTXPO, and announced the return of the Leadtime Leader award, we also continued to cover some of your favorite topics. Take a look at what you might have missed in March.

Read MoreLeadtime Leader Award Honors the Many Faces of Moldmaking

This Award is not only for big mold shops! Check out the criteria for entering our 2024 competition.

Read MoreRead Next

Dynamic Tool Corp. Wins MoldMaking Technology’s 2024 Leadtime Leader Award

Dynamic Tool Corp., a provider of engineered tooling solutions based in Menomonee, Wisconsin, has been awarded MoldMaking Technology’s prestigious 2024 Leadtime Leader Award. The announcement was made during a live awards ceremony at the Plastics Technology booth, where owners Steve and Ken Eberle accepted the award on behalf of their team.

Read MoreVIDEO: Meet Our 2024 Leadtime Leader, Dynamic Tool Corp.

Dynamic Tool Corp. team members meet with MoldMaking Technology editorial director Christina Fuges to discuss their innovative engineering, design and development solutions for optimizing the production of plastic components and products. They also discuss the team that makes it all happen, both now and in the future.

Read MoreMMT Chats: Dynamic Tool Corp. Is Moving Forward and Getting to the Front of the Line with Customers

MoldMaking Technology Editorial Director Christina Fuges gets the scoop from our 2024 Leadtime Leader Award Winner Dynamic Tool Corp., on the company's future, their trade show experience, finding new talent and the impact of this industry recognition.

Read More