The Danger Zone

Spindle crashes can have costly consequences. Collision protection systems can help minimize the damage.

A spindle collision is one of a shop’s worst nightmares. The results are often costly and catastrophic, and typically include broken spindles and tools, damaged parts, mangled clamping systems, and even crushed machine castings. Broken spindles are expensive and complex to repair. They equate to days of machine downtime and the loss of revenue as shops fall behind in their production schedules. Just one spindle crash can potentially cost a shop more than $50,000 in repairs and production loss. Even in operations with the best programmers and operators, spindle collisions will inevitably happen. Fortunately, shops can lessen the blows of those collisions with spindle protection systems.

Collision Cause and Effect

The two main culprits of spindle crashes are programming errors and setup mistakes. The easiest way to prevent crashes due to programming issues is to run the program through a CNC verification system that simulates the complete interactions between the part and the machine before the program is ever sent to the control. This procedure can prevent the vast majority of collisions.

However, an operator may inadvertently place the workholding system in the wrong location or use the wrong tool, toolholder or toolchanger position. A software verification system is unable to detect such setup problems, so it is important for shops to pay careful attention to machining plans and machine setup specifications.

In addition to miscalculations prior to machining, unforeseen tool problems such as a cutter break can cause collisions as well. In these instances, the collision protection system is the only thing that stands between the machine and severe damage.

There are a handful of spindle collision protection systems available on the market, each with its own advantages and disadvantages. These systems include those based on motor current monitoring, the use of aluminum bushings or magnetic technology. However, shops should keep in mind that some of these collision protection systems, including the magnetic type, cannot be retrofitted to existing machines, so the decision about which type of system to employ has to be made at the time a new machine is purchased.

Spindle protection systems provide the most benefits for multi-axis machining operations and heavy-duty cutting applications, as well as for those shops that run multiple machines with a variety of controls. With multi-axis machining, the amount of simultaneous movement in so many directions makes the machine vulnerable to a crash. Heavy-duty cutting involves significant levels of torque, and in the event of a collision, upwards of 10 tons of force can potentially get thrown against the spindle. Shops that run several machines, each with different controls, run a strong risk of human error that can increase the chances for spindle collisions. For example, operators may forget the differences between machines/controls and leave too much tool overhang for a particular machine or use the wrong zero points. In any case, all these scenarios put shops in the spindle collision “danger zone.”

The Options

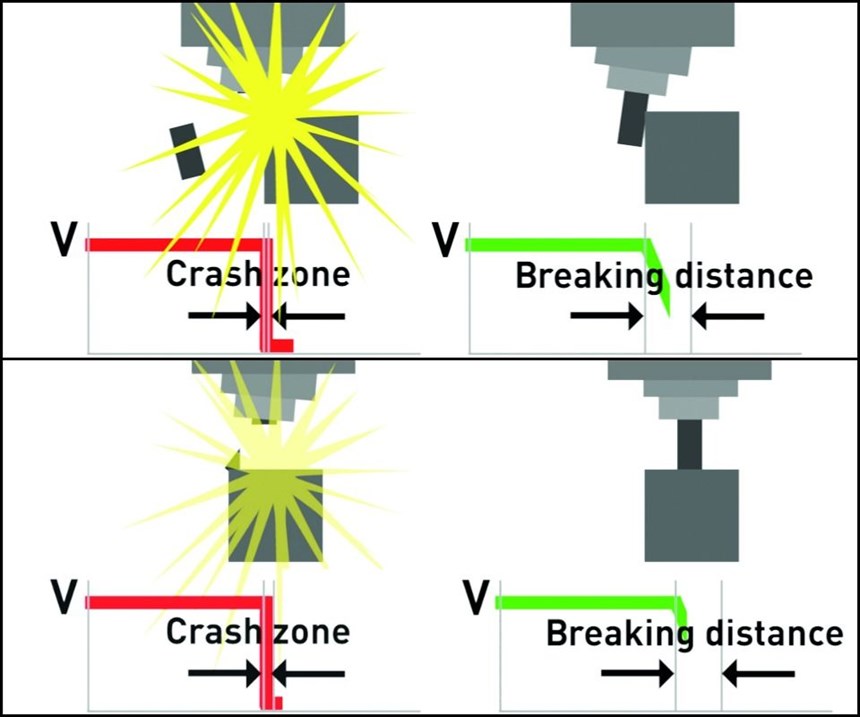

Of the three main types of systems, motor current monitoring offers the most basic form of protection from spindle collisions. Sensors detect when the motor draws too much current and relay that information to the machine’s control, which then halts the machine’s movements. This process takes place within 5 milliseconds, but even that incredibly short window leaves the machine vulnerable. By the time the machine stops, the damage may be done, mainly to the spindle bearings, servomotors, tool and workpiece. It should be noted that current-monitoring systems are designed mainly to save motors from overloads of current and prevent major damage to machine castings, as opposed to providing actual protection from spindle collisions.

Types of collision protection systems that rely on aluminum bushings apply them around the screws that hold the machine spindle in place on the Z axis. In the event of a collision, the bushings collapse and protect the spindle bearings. Unfortunately, these types of systems really only protect spindles during Z-axis plunging operations and not when a crash occurs in the X or Y axis.

While aluminum-bushing-type systems protect the spindle in the event of a Z-axis crash, the machine will still need extensive maintenance to return to peak performance. To do so, shops must remove the spindle and replace all the crushed aluminum bushings, which will take at least a day or two, provided that replacement bushings are immediately available. Also as a result of the crash, machine kinematics and zero points could be completely misaligned, so the machine will require a total recalibration to ensure its movements are back within factory specifications.

Systems that use magnets represent one of the latest innovations in spindle collision protection technology. What sets them apart is that they not only protect spindles in all five axes of machine motion, but they also reduce, and in most cases eliminate, the need for any post-collision maintenance or intervention, as well as prevent dull cutting tools from wearing on workpieces.

Magnet-based collision systems are self-contained mechanical protection units composed of magnets within the spindle housing. These magnets separate and enable the machine to essentially “spring back” to its normal position after a collision. Sensors on the magnets register movement and automatically trigger the machine to abort its current operations. As a result of this seemingly instantaneous detection, spindles can experience 90-percent less force during crashes. While the system has the same 5-millisecond lag time as others, the magnets provide a degree of flexibility that protects the spindle and other machine parts in the time it takes the machine to stop. And because the magnets reposition the spindle after an impact, they eliminate the need to manually recalibrate it or the machine.

However, after a crash on a machine with a magnet-based collision system, the tool and toolholder will likely need to be replaced. It is also recommended that operators visually check the spindle for potential damage and run a geometric check to ensure all other components of the machine are positioned properly. Once these tasks are completed, the operator can simply load a new tool, and the machine is ready to go. The entire process takes a few minutes.

This type of system is most effective when the machine operates in a setup or safety mode in which the slower speeds exert less force and give the machine system more time to react. Because most collisions happen during a dry run or setup, guaranteed protection during those conditions is essential.

At higher feed rates, some minor damage may occur, but it usually is dramatically less than what would occur without the magnet-based collision system. For example, a high-speed crash might require a bearing replacement as opposed to a whole new spindle. Even though a magnet-based system works best at slower speeds, it still should perform optimally under heavy cutting loads, and protect the machine and workpiece from cutting tool breakages.

Unlike other crash-protection systems, a magnet-based collision system also will stop dull/worn cutting tools from continuing to cut, which reduces the number of parts that will be scrapped due to poor finish quality. Dull tools exert more force on the spindle and the machine’s axis movements, and this increased force triggers the magnet-based collision system to then stop the machine.

Protecting a machine against the wide range of collateral damage that can result from a spindle crash is key to a shop’s bottom line. While there are other steps a shop can take to reduce the chances of a collision, those efforts cannot be 100-percent effective. Shops can further lessen the risk with the right spindle protection system.

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreRead Next

Another Look at EDM Generator Technology

Advancements in fully digital sinker EDM generators offer benefits in mold maintenance, process efficiency and electrode wear.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More