Technology Tuesday: EDM Success

Cruise through this week’s Technology Tuesday slideshow to see EDM units that shops across the country have used to increase capacity and leverage greater efficiency in their processes.

As European correspondent Barbara Schulz wrote recently in her International Perspective column for November, “Although it is often declared dead, electrical discharge machining (EDM) clearly continues to live and has firmly established itself within manufacturers’ process chains.” She is quite right! For this week’s Technology Tuesday, I’ve put together a slideshow of EDM units in companies across the country that MoldMaking Technology has featured in case studies. Links to the relevant articles are listed in the captions. To see more content on EDM, check out the EDM Zone.

As many of you know, MoldMaking Technology’s case studies provide real-world success stories in which the “hero” is a product or service that helped a mold-industry user solve a critical problem or address an important challenge.

Have a success story that would make for a good case study that you would like to share? Reach out to Senior Editor Cyndi Kustush at ckustush@gardnerweb.com.

Related Content

-

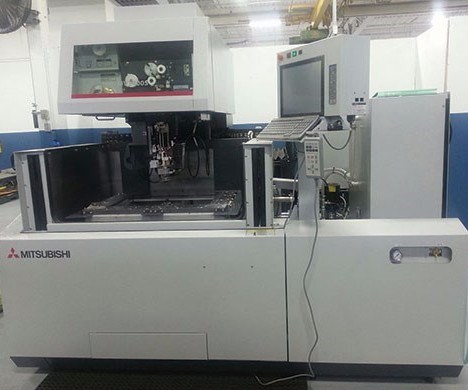

Quality Tool & Die Enhances Performance With Advanced EDM and Milling Technologies

The adoption of Mitsubishi wire and sinker EDMs, along with the OPS Ingersoll five-axis milling machine with automated cells, has enabled unmanned operations and improved precision. As a result, QTD has expanded its facility, grown its workforce and increased its business by 10-15% annually.

-

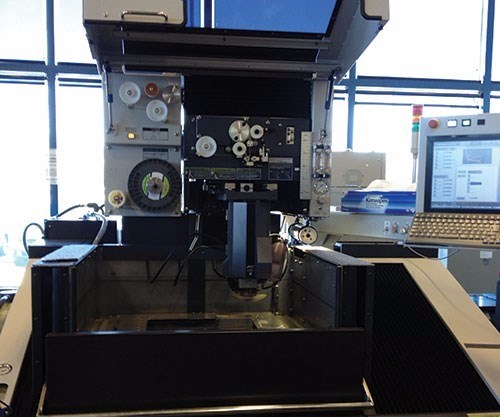

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

-

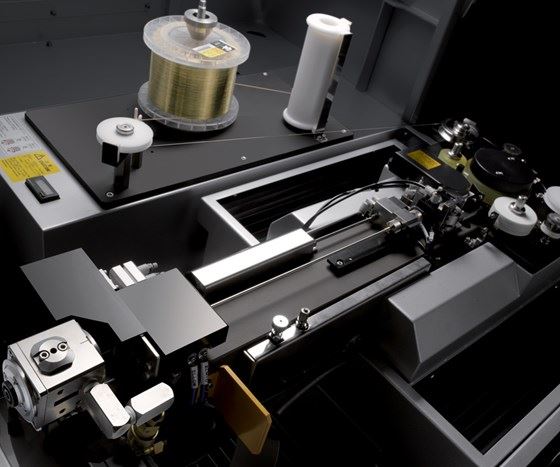

Extensive Evaluations Build The Plastek Group’s EDM Arsenal

Sinker and wire EDMs selected for speed, volumetric accuracy, surface finish, reliability, cost of ownership and extensive warranty.

.jpg;maxWidth=300;quality=90)