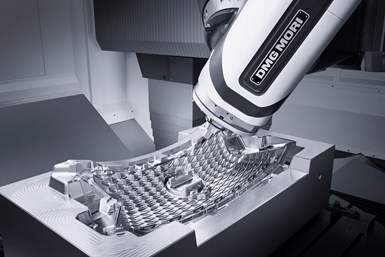

Photo Credit, clockwise from top left: GF Machining Solutions, IMCO Carbide Tool, DMG MORI USA and Capture3D

With Christmas right around the corner, MoldMaking Technology is gifting you, our readers, with an annual top-viewed article series covering products, profiles, tips and case studies, available each Monday leading up to the new year. Each article highlights the 10 most-viewed pieces of content of 2022 —this is based on their number of page views as reported by Google Analytics.

To start off the month of December, we’ve shared the top five most-viewed products of 2022 in the following categories (note that analytics were pulled from Jan. 1, 2022 to Nov. 28, 2022):

- Cutting Tools

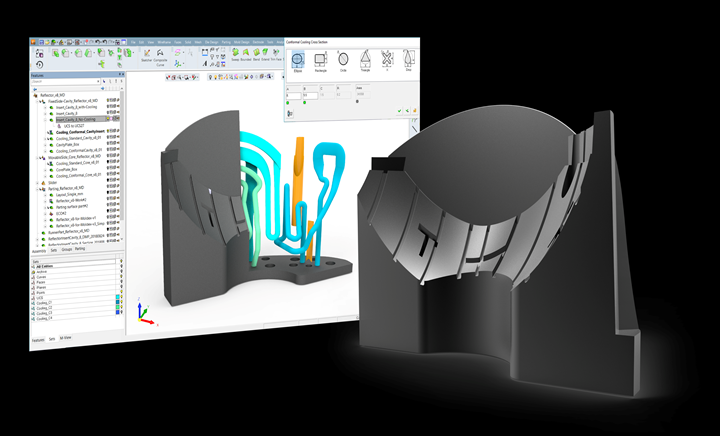

- Additive Manufacturing

- Mold Materials

- Hot Runners

- Mold Components

- Machining

- EDM

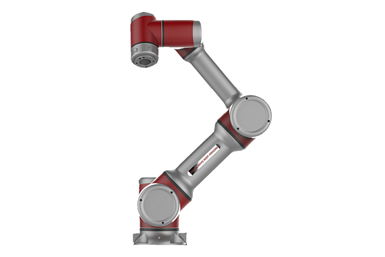

- Automation

- Inspection and Measurement

- Mold Maintenance, Repair and Surface Treatment

Enjoy some of the favorites below, or see what you might have missed! And don’t forget to look for some of these items in our upcoming January 2023 print and digital issues!

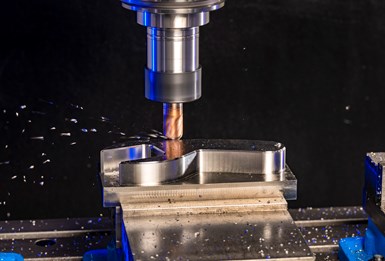

5. Ball-End Tool Contours, Chamfers and Finishes in One Pass for Most Materials

IMCO Carbide Tool launches the Pow•R•Arc ball-end cutter, the newest of IMCO’s high-performance cutting tools. The company says its product is all about speed; the Pow•R•Arc is designed for contouring and chamfering at the fastest possible speed and feed rates in most materials, even cutting smoothly in workpieces with dissimilar materials, with no digs or handwork needed.

4. High-Feed Performance for Small Parts

Ingersoll’s new NanoFeed technology provides mold builders with exceptional high-feed milling performance for machining of miniature components and smaller part features. NanoFeed is a 20° high-feed indexable insert design that Ingersoll claims will replace smaller diameter solid carbide end mills in a variety of applications.

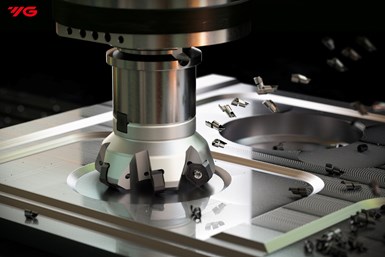

3. Rough and Mirror-Finish Face Milling Performed with Same Cutter

Global cutting tool company YG-1 Tool Co. announces that it is giving face milling a whole new dimension with the FM10 PNMU indexable inserts and cutter. This latest innovation from YG-1 provides rough face milling with high removal rates and optimized surface finishes with the same insert and cutter, an ability that is not typically available for most mold builders or general metalworkers but is considered the single most important benefit of the product for these end users, particularly as it reduces cycle time and enables control over insert inventory.

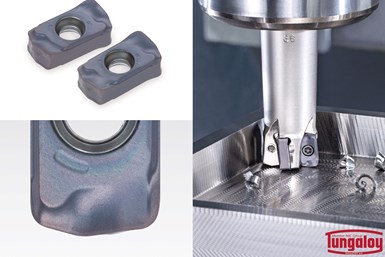

2. Inserts Improve High-Feed Milling Performance in Exotic Materials

Tungaloy America has expanded its DoFeed high-feed milling cutter series by adding six LNMU0303UER inserts. DoFeed, a high-feed milling cutter series, features economical double-sided inserts with four cutting edges, offering a wide variety of cutter body diameters and styles.

New LNMU0303UER inserts are available in Size 03 and designed to provide long tool life, the company says. These UER inserts are interchangeable with existing ZER inserts on the same cutter body.

1. Five-Flute End Mill Delivers Dynamic Performance

The M.A. Ford TuffCut XV Series XV5CB is said to be a stable, reliable solution for deep, dynamic milling applications, especially developed for mold builders. The five-flute chipbreaker end mill was designed to deliver exceptional metal removal on steels and stainless steels. Offered in both 3xD and 4xD length of cut options, M.A. Ford says the XV5CB increases productivity through its aggressive stepover capabilities.

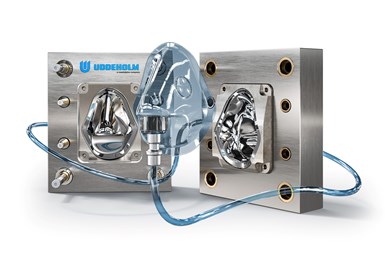

5. Corrosion-Resistant, High-Hardness Mold Steel for Optimal Surface Finishes

Uddeholm’s Tyrax ESR is a premium corrosion-resistant and high-hardness (up to 58 HRC) mold steel. It offers excellent polishability, the company says, making it the obvious choice for applications where surface finish is of the highest importance. Moreover, a high-gloss surface finish can be achieved in three polishing steps compared to five steps for AISI 420 ESR, reducing overall polishing time by 40-50%. Uddeholm Tyrax ESR is reported to be a suitable upgrade from AISI 420 ESR, AISI S7 and AISI 440C.

4. Self-Venting Mold Steel for Defect Prevention

Quality assurance always begins with the end product in mind, so planning for quality in the design of a mold should always be the first step. One consideration is eliminating trapped gas in a mold using Vortex self-venting mold steel offered by Molder’s World. According to the company, complex parts, especially for medical, aerospace and automotive industries, typically have intricate details that are “difficult to fill,” largely resulting from said trapped gas getting in the way inside the mold cavity.

3. Pre-Hardened Mold Steel Material Increases Through-Hardened Ability

Global supplier of high-quality mold materials Finkl Steel highlights its patented pre-hardened mold steel grade MD Xtra. The through-hardened material is said to achieve high impact strength, enhanced thermal conductivity and is a solution for deep cavity applications.

According to Finkl Steel, MD Xtra has proven through-hardenability on molds up to 45" thick, with hardness loss from surface to the core of roughly 3 HRC points. The material has been specifically engineered to support laser hardening, chrome plating, nitriding, texturing and has excellent weldability.

2. Corrosion-Resistant, Highly Machinable Tool Steel

Deutsche Edelstahlwerke (DEW), a plastic mold steel producer and member of Swiss Steel Group, highlights Opticut, a tool steel that combines improved machinability with optimized corrosion resistance. DEW says these features are paramount, as corrosion-resistant stainless steel is not only required for molds, but is also essential for mold frames, which are typically produced in large machining volumes.

1. Modified Composition Enhances Stainless Steel Capabilities

Photo Credit: Edro Engineering

Edro, an exclusive U.S. distributor for Böhler, introduces the company’s newly developed M333 Isoplast stainless steel. Manufactured via a new melting technology, M333 offers moldmakers what is said to be best-in-class polishability, enhanced thermal conductivity, optimized toughness and exceptional corrosion resistance.

According to Edro, testing has shown M333 Isoplast to exhibit up to four times the toughness levels seen in 420 stainless steel and almost matching the toughness of H13. This enables molds to have the benefits of stainless steel without the risk of cracking.

1. Ejector Pins With Ventilation Surfaces Improve Mold Performance

Hasco America unveils its new ejector pins Z401 with ventilation surfaces to ensure that the air in the cavity can easily escape, improving mold performance. Specific to this product, the extra-long ventilation surfaces extend over a large part of the ejector pins, so the pins can be easily and individually shortened to the desired length.

2. Guide System Offers Precise Positioning in One System

Agathon Machine Tools continues to highlight its novel Guide System Plus, which performs guiding and centering tasks for the precise positioning of mold halves/mold component using only one system. Ideal for cleanroom, high-precision, micro-injection molding and high-temperature applications, this innovative reinterpretation of existing guiding and centering systems is said to increase planning reliability in production, boost productivity and reduce overall production costs.

3. Online Mold Base Configurator for Simplified Mold Base Ordering

PCS Company has released its easy-to-use, three-step online Mold Base Configurator for configuring and ordering high-quality mold bases. Mold builders have access to a range of configurator options including Frames 7.875 x 7.875 – 23.75 x 35.5, A and B plate thickness from 0.875 to 5.875 and #3 and #7 Steel. Machining features and components are able to be added or omitted, as needed. Bill of materials (BOM), CAD and 3D View enable simplified verification. Users are also able to generate a quote, which can be accessed at any time if ordering at a later date.

2. Collapsible Cores Optimize Molding Threads and Undercuts

DME introduces its advanced solution to molding threads and undercuts with its new S-Core Collapsible Cores. The S-Core is a dynamic design that can be produced in six, eight or 12 segments, enabling parts to be produced as small as 6 mm and as large as 400 mm. The length and depth of the part feature dictates the number of segments required to release the undercut.

Six segments has three large and three small slide segments each. According to DME, this option provides sufficient collapse for undercuts up to 600 mm.

1. High-Conductivity Core Pins

Regal Components Inc. has introduced a line of high-performance beryllium-free copper-based alloy core pins for high-volume, high-heat plastics molding applications. The Regal BFP type high-conductivity core pins are made from a C-18000 beryllium-free copper-based alloy providing 95-98 Rockwell B (20-25 Rockwell C) hardness. Regal says the alloy offers 10 times better heat conductivity than steel and two times better conductivity than beryllium copper pins, while also resisting thermal stress, wear and abrasion.

Photo Credit: Regal Components

5. Rotating Wire Function Cuts EDM Wire Consumption, Optimizes Mold Cutting Conditions

With the addition of the patented wire rotating function, iGroove, Sodick says it has literally put a new spin on the capabilities of wire EDMs. Featured in the company’s ALN and ALP wire EDM lines, the addition of iGroove reportedly show improved results in accuracy and surface quality while simultaneously reducing wire consumption — this machine lineup is especially suited for thick workpieces (60 mm or greater).

The iGroove function rotates the wire from the top to the bottom of the workpiece, ensuring the entire surface of the wire is used during the cut, and eliminating the need for taper compensation due to wire wear. This twisting mechanism creates a consistent, fresh electrode surface from the top of the workpiece to the bottom, Sodick notes, and, as a byproduct, the wire feed speed can also be slowed down.

4. Fast Wire EDMs Exhibit Removal of 3D-Printed Metal Parts From Large Build Plates

EDM Network exhibits its newest, mid-sized Fast Wire EDM machine, EDMMax656W, developed for the laser powder bed fusion (LPBF) 3D metal printed market. The Fast Wire EDM was designed to quickly remove 3D-printed metal parts from the larger build plates — 625 x 625 mm in size. More recently, EDM Network notes that small molds are also being 3D printed to be used in this type of application.

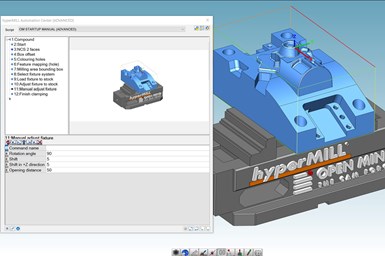

3. Wire EDM Function Eliminates Wire Breakage, Reduces Consumption

The new iWire function from GF Machining Solutions automatically identifies and adapts wire speed to changing erosion height conditions during the wire EDM process. This capability reportedly eliminates wire breakage while reducing overall wire consumption per job, in some instances by as much as 29%.

Featured on new GF Machining Solutions’ Cut P Pro Series wire EDMs, the iWire function works in tandem with the company’s Intelligent Spark Protection System (ISPS), both of which are part of the company’s Uniqua control.

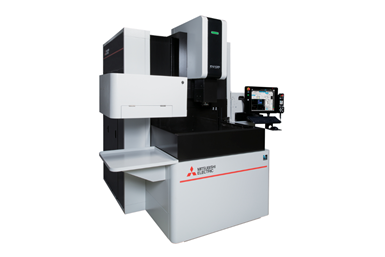

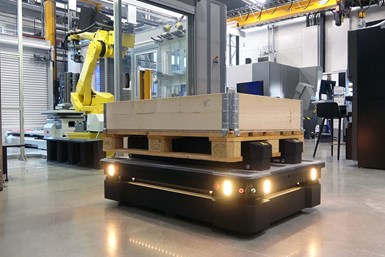

2. EDM, Precision Milling Technologies Highlight High-Precision Features for the Moldmaking Industry

MC Machinery, a subsidiary of the Mitsubishi Corp., showcases its latest EDM and precision milling technology, including wire and sinker EDMs, machining centers and automation, at IMTS booth #338129.

Newly featured sinker EDMs include the Mitsubishi SV12P and SG12 and Gantry Eagle 800. The former features mAIsmart IDPM3 (Intelligent Digital Power Master Control), which uses a state-of-the-art sensor to monitor the total amount of electrode contact area within the workpiece, so the system can automatically changes power conditions based on real-time measurement feedback to produce the most efficient burn. This results in up to 40% less electrode wear and up to 30% reduction in machining time for moldmakers.

1. CNC EDM Sinker Sets Standards for Mold Manufacturers

Belmont Equipment and Technologies says its exclusive Maxicut Series CNC EDM sinker machines have been setting standards and creating solutions for the moldmaking industry since 1994.

The MX-140XW CNC EDM Sinker, featured at IMTS 2022, is characterized by a programmable work tank level that is said to provide excellent operator ergonomics for loading and unloading, while maximizing unattended job operations that have different oil level requirements, the single most important benefit for a mold builder. This sinker is 87" wide x 83" deep, with X, Y and Z travels of 15.7", 11.8" and 15.7", respectively. Available open height is 25.7" and the maximum workpiece weight is 1,760 lbs.

5. Hand-Held Metrology-Grade 3D Scanner Provides Measuring Freedom

Automated Precision Inc. (API), inventor of the Laser Tracker, has launched a thoroughly re-engineered version of its iScan3D hand-held 3D scanner. iScan3D is the third-generation version of API’s metrology-grade scanner. It is designed for portable shop floor dimensional inspection and scanning markets to provide both accurate measurements and point-cloud generation from a single-handed ergonomic sensor.

iScan3D, with integral process controller, connects with API’s Radian Six Degrees of Freedom (6DoF) Laser Tracker to accurately monitor scanner position and deliver high accuracy measuring and scanning.

4. Multifunctional Laser Handheld 3D Scanner

Shining 3D, a global provider of technologies for 3D digitization and 3D inspection, has expanded its FreeScan UE series of blue laser metrology 3D scanners with the FreeScan UE Pro.

FreeScan UE Pro inherits the high-precision, metrology-grade accuracy, and lightweight design of FreeScan UE, while improving the ability of fine scanning and global precision control of large-scale workpiece scanning, according to the company. It adopts 26+5+1 blue laser lines and has a built-in photogrammetric module. Taking into account speed, accuracy and details, the 3D metrology solution can be applied to different sized scanning scenarios and perform metrology-grade accuracy inspection, reverse design, additive manufacturing (AM) and other applications.

3. Coolant Retrofit Systems, Collets, Precision Probing Expand Toolholding Offerings

Rego-Fix showcases innovations that extend the company’s Swiss precision beyond toolholding. Featured technologies include the 3D-EdgeMaster measuring device and MasterBar test arbors — both new product entries for setup and test measurement. Other highlights include expansions to the company’s existing lines of internal coolant retrofit systems with additional flexibility for high-speed spindles and for turning centers, as well as other collet offerings.

Rego-Fix serves several industries, including mold and die, seeking to establish process safety, ensure repeatability and reduce complexity when machining and measuring molds.

2. Precision Handheld 3D Scanner Delivers Fast Digitization of Molds

Capture 3D presents the T-Scan hawk, a portable laser scanner that rapidly collects precision 3D data. The handheld 3D scanner offers GOM Inspect 3D inspection software, integrated photogrammetry, multiple laser sources and three application-focused scanning modes, providing the flexibility needed to accomplish various diverse tasks, including the scanning of a range of small to large molds.

As a lightweight, mobile, handheld 3D scanner, the T-Scan hawk is small enough to travel with and bring directly to the object it will scan, a benefit for mold builders when the mold is too large to move, or the object is fragile; since the mold can be inspected in place, the chances of creating waste and increasing costs due to damaged molds is virtually eliminated. The T-Scan hawk’s portability also enables 3D inspection in tight places.

1. Compact Digital Inspection Microscope Supports Immediate Information Capture

Vision Engineering announces the launch of VE Cam, a simple-to-use compact digital inspection microscope for a wide range of applications. It made its North American debut at APEX Expo in January 2022.

The VE Cam is a complete, standalone system for circuit board examination, PCB debug activities or for discovering imperfections, and to trace problems in a wide range of industrial applications. It is ideal for applications from goods-in quality inspection to shop floor inspection of turned parts, and suitable for manufacturing electronics, plastics, ceramics, mechanical engineering and additive manufacturing (AM).

Related Content

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

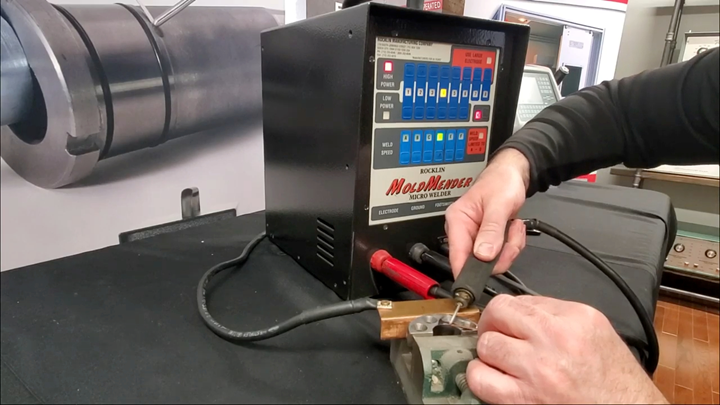

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More