All According to Plan

This moldmaker influences its own destiny by staying true to itself, knowing exactly where it wants to go, and ensuring everyone in the organization understands how to get there.

Tim Bartz and Justin McPhee decided they’d had enough. The year was 2010, and the co-owners of Mold Craft Inc. were regularly putting in 65-hour workweeks. That’s not to say these seasoned industry veterans minded the long hours. Rather, they couldn’t help but feel as though all their hard work was for naught.

Granted, staying busy in the wake of a severe economic downturn wasn’t a bad thing, at least not on the surface. Moreover, the Minneapolis-area manufacturer of precision plastic and MIM injection molds had managed to keep up with delivery targets while also maintaining the stringent quality standards on which it had built its reputation. Nonetheless, this supposed success wasn’t reflected in profit margins, which hovered barely in the black regardless of the amount, quality or timeliness of the shop’s work. Shift after shift, the Mold Craft team kept the shop humming and even found new efficiencies, but rewards remained fleeting and the future uncertain. “We needed to take a step back,” McPhee recalls. “We were spending too much time working in the business and not on the business.”

The changes of the past few years prove that forcing focus on the bigger picture was well worth it. Now celebrating its 50th year in operation, Mold Craft has reaffirmed just what type of company it is. It has redirected resources accordingly to avoid wasted effort, particularly on the front end of the build, and it has articulated a detailed vision for where it wants to be in the future. Identifying and tracking relevant metrics has illuminated how far the company has come along that path and what’s required to speed the journey. All of this information has been condensed into a single-page business plan that provides a roadmap for the entire company. Equally simple sub-plans governing individual departments filter broader goals throughout the organization so that all 41 employees know how best to contribute.

As a result, morale has improved because employees understand the importance of their contribution and their role in the broader organization. Improved communication, both in and among different departments, limits misunderstandings and helps disparate parts of the shop to act in concert. Since 2010, the shop’s average on-time delivery rate has improved from less than 80 percent to 97.8 percent, and its quote-capture rate has more than doubled, Bartz says.

A Culture of Perfection

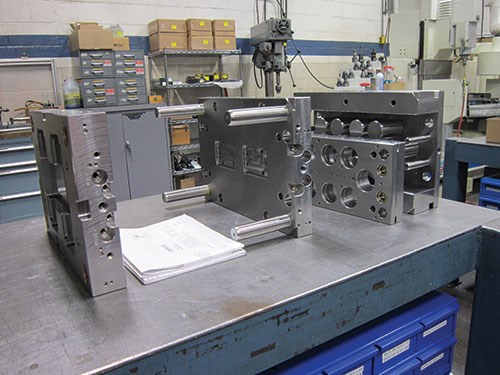

Finding focus hasn’t changed the essentials of how work flows through the shop. Granted, the technology on the 12,000-square-foot floor is always in flux—the past year alone has seen the addition of more than $1.1 million worth of new equipment—but the basic foundations of the process were laid in the 1980s, Bartz says. That’s when Mold Craft purchased its first standardized workholding fixtures to move electrodes from mill to sinker without re-indicating. In 2007, the shop installed its first robot to save time and money for customers. Today, three robots feed not just electrodes, but cores, cavities and inserts as well, often on an as-needed basis within in the same cell.

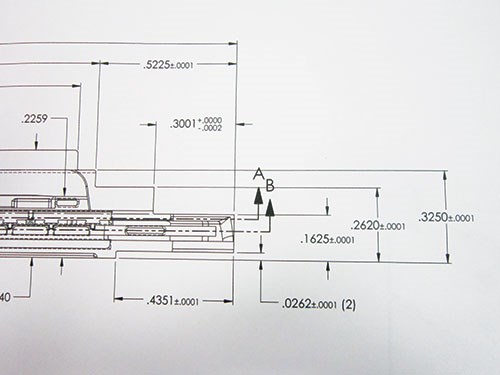

However, the shop discovered early on that technology alone wouldn’t be enough to bring it into the future. The true differentiator is the people behind it, Bartz says, and their roles had to change. Robots and standardized workholding don’t work well with variation, so executive decisions about how to machine a critical feature or set up a workpiece could no longer be left to a single toolmaker. In short, much of the “craft” at Mold Craft has moved to the front end, where designers engineer every fit and clearance between components to ensure true interchangeability. By the year 2000, “working layouts” had been replaced by fully detailed and tolerance prints for every unique item in a mold. Once the prints arrive on the floor, operators follow the predetermined manufacturing process to the letter. Bartz says this automation-centric production strategy enables Mold Craft to regularly achieve tolerances as tight as ±0.0001 inch without spotting. (In fact, the shop doesn’t even own a spotting press.)

Developing a detailed process in advance to ensure jobs get done right the first time is ideal for high-end tooling involving large numbers of interchangeable inserts. However, molds with less-stringent requirements can turn the advantages of the shop’s production strategy into a noose—one that, prior to 2010, often choked off any chance for profit before the steel hit the floor. “At Mold Craft, doing a quote right takes days, not hours,” Bartz explains. “We can’t afford to just throw darts at the board and quote millions of dollars a day.” Once a quote was awarded, an ingrained culture of perfection made lowering standards difficult even when work called for it, he adds. As he puts it, “Tolerances don’t really mean a lot when your people strive to make everything to zero.”

Therein lay the crux of the problem that led the shop to adopt the one-page business plan. After taking the reins at Mold Craft in 2007, Bartz and McPhee didn’t have much time to acclimate to their new positions before the bottom dropped out. Before long, they found themselves forced to pursue work that the shop simply wasn’t set up to handle cost-effectively. Even as the economy improved, they lacked a reliable system for identifying customers that appreciated the level of quality Mold Craft could provide (and for weeding out those that didn’t).

Crystallizing a Vision

Enter Ted Capistrant, whom the co-owners met at a business conference around the same time they decided they were tired of spinning their wheels. Business planning is a big part of Capistrant’s focus at Profit Builder Network, the Minneapolis consulting firm he founded in 2005, and Mold Craft’s leadership was enthused by his ideas. “We had discussed doing a business plan before, but everything we had seen was so extensive—pages and pages, like a quality manual or something,” says Jim Liddell, sales manager. “That just seemed too overwhelming while we were focused on getting orders and keeping the doors open. Ted’s single-page concept seemed like wizardry or Jedi mind tricks.”

That’s not to say Mold Craft expected a quick, effortless process. Indeed, given the realities of running the shop, finalizing the plan took a year and a half of soul-searching and periodic consultations with Capistrant. Rather, they recognized that the end result would be something they could actually use. That is, they recognized that coming face-to-face with the crystallized essence of the company’s vision day in and day out would help avoid misplacing priorities or inadvertently veering off the chosen path, Liddell says.

The business plan is organized into four quadrants: Vision, which outlines where the company sees itself in the future (The current version, unveiled earlier this year, projects to fiscal year 2017.); Guiding Principles & Strategies, which broadly outlines the values and priorities supporting the vision; Key Performance Indicators (KPIs), which identifies how to measure progress toward realizing the vision; and Milestones, which identifies improvement projects to be completed within the coming year.

For example, one long-standing line item under Vision reveals that Mold Craft aims to target “discerning, perfection-driven customers.” To that end, Guiding Principles & Strategies dictates that the shop “direct 80 percent of resources toward customers that deserve attention,” specifically those in such industries as medical disposables and consumer products. KPIs include such line items as winning a specified number of contracts per year for molds with at least eight cavities, or for tooling valued at a certain minimum dollar amount. The next major milestone is adding another customer with enough sales to be ranked as one of the country’s top 100 injection molders.

Taking Action

If these line items seem broad, that’s because they’re supposed to be. While plotting the course is a job best-suited for those at the top, the task of actually steering the vessel falls to Mold Craft’s employees, Bartz says. To that end, the master plan serves as a guide in the development of single-page sub-plans that outline specific goals and priorities for individual departments.

The dramatic improvement in the shop's quote-capture rate was among the first and most significant examples of putting the plan into action. Although the master plan called for attracting a certain type of customer in broad strokes, the objectives and action items on Liddell’s sales and marketing sub-plan outlined how exactly the shop planned to get there. One example was the development of a “filter” to weed out RFQs that aren’t likely to pay dividends.

In essence, the filter is a checklist of questions used to obtain as much information as possible about the prospective customer’s priorities without getting designers and engineers involved. For example, a custom molder might be asked whether it has already estimated the cost of tooling and incorporated that into the price quoted to an OEM customer. The answer can say a lot about the prospect’s knowledge base, as well as the level of service it expects to receive from Mold Craft. Other common questions cover how many other toolmakers received the same RFQ and the timing of the order. Liddell emphasizes that the filter isn’t just a static list. Questions tend to vary according to the specifics of the work and the nature of the prospective customer.

Developing the filter was listed as a milestone on the sales and marketing sub-plan. As such, checking it off the list represented significant progress toward a line item under Guiding Principles & Strategies: “Verifying that customers align with Mold Craft’s values and fit our target profile before dedicating valuable resources.” The filter was judged a success because it has contributed to fulfilling such KPIs as decreasing average RFQ turnaround from 10 to 7 days. Other notable milestones the department has reached in recent years include unveiling a new website and implementing a ranking system for prospective and current customers. All of these strategies, milestones and KPIs support broader items in the sub-plan’s vision section. These include such goals as increasing revenue by 10 percent each year and “developing efficient processes in customer needs discovery, customer ranking/filtering and CRM management.”

All Aboard

Keeping employees informed and engaged is a critical factor in taking effective action on goals filtered down through the individual sub-plans, McPhee says. To that end, the shop hosts monthly “stand-up” meetings to update employees on progress toward goals and what might be in store for the future. These meetings ensure each individual fully appreciates how his or her efforts contribute to the company’s overall vision. For instance, everyone can discuss why the master plan calls for elevating brand recognition and why investing in a new website is important to that goal. Similarly, software engineers working on KPIs related to refining the shop’s use of Epicor ERP software fully understand why that needs to be done.

Employees also learn about the challenges faced by coworkers in other areas, McPhee adds. This can not only limit misplaced resentment, but also lead to changes that improve overall synergy. Delivery time is a prime example. Previously, the clock started ticking as soon as Mold Craft received a purchase order. Pressure to turn the job around trickled all the way down to the shop floor regardless of extenuating circumstances, such as a customer not sending needed information until two weeks into the project. Now, in keeping with the shop’s engineering-heavy production strategy, deadlines are based on design approval. This change has alleviated pressure on people with no control over the data or approval process of the customer. “Our customers respect our approach and are happy with our ability to deliver the project when we say we will,” McPhee says. “This approach holds everyone accountable, and all project milestones can be planned and monitored more easily.”

Finally, the meetings offer a chance to show employees how much they’re appreciated. Departments and individuals are always celebrated for their role in knocking action items off plan lists and other accomplishments. In addition, the shop recognizes one employee every month whose contributions went above and beyond the norm, as well as birthdays, employment anniversaries and other milestones. Going over the workload at hand, incoming orders (both promised and booked) and the company’s overall performance and outlook also helps employees plan (for example, if someone is looking to book a vacation or buy a house).

These sorts of activities don’t directly impact the bottom line, but they are no less important in the long term. After all, there’s a reason the shop pursues only the most difficult work. “Anybody can buy equipment or do a business plan, but our people have a passion, a pride of ownership, that makes us who we are,” Bartz says. “They won’t let something out the door that’s not right.”

Related Content

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreMMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreTop 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More