Automation System Loads up Expandability, Scalability and Precision for Moldmakers

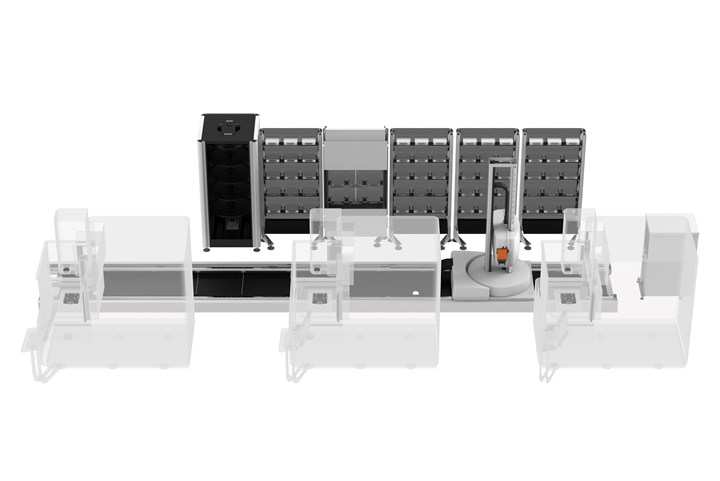

The expandable, scalable, open architecture of the System 3R Transformer system by GF Machining Solutions permits integration of various technologies to optimize mold machining operations and meet any facility’s requirements.

Automation technologies, like the System 3R Transformer modular automation system from GF Machining Solutions, boost productivity, profitability and global competitiveness for moldmaking shops. It is expandable and scalable, and its adaptability and flexibility ensure that it will never be too specialized or too small to meet a facility’s future requirements.

OEM automation systems often are designed to integrate certain machine tool brands or styles. The open architecture approach of the Transformer system permits integration of differing manufacturing technologies including mills and turning centers, EDM machines, measurement devices and even part cleaning equipment. Unconstrained by compatibility issues, individual mold machining operations can be optimized and incorporated to achieve full automation of an entire process.

The basic components of the Transformer system are a robotic pallet changing unit and modular racks or rotating magazines that store pallets fitted with referencing chucks from System 3R. The chucks provide repeatability of 2 µm and enable the transfer of parts from one machine to the next without the need to check positioning or repeat setups.

To handle as many as 12 machines, the pallet-changing robot rides on a modular rail system. The rail system is made up of standardized sections that can be quickly added and linked to produce the length needed to service the number of machines desired for the cell.

According to GF Machining Solutions, payback on the investment in a Transformer system is rapid, a result of significantly increased machine utilization. The system’s accuracy and reliability permit lights-out operation that multiplies machine use by a factor of three or four.

Related Content

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.