In-House Surface Treatment Services for Molds, Embossing Rolls

As Mold Surface Textures celebrates 20 years in industry, the company highlights various services it offers for texturing, repair, polishing and more.

Founded in 2004, Mold Surface Textures’ (MST) core mission is to provide surface texturing, polishing and texture repairs in the Upper Great Lakes region for molds and embossing rolls. That mission has remained a constant as MST enters its 20th year in business.

MST customers rely on the company for in-house and on-site texture repair; in-house mold repair; mold polishing to Class A-3 diamond finish; mold and embossing roll texturing (mechanical, photo-etch and laser); noncontact texture mapping; CAD/CAM programming; sinker and wire EDM; CNC machining; and water jet cutting.

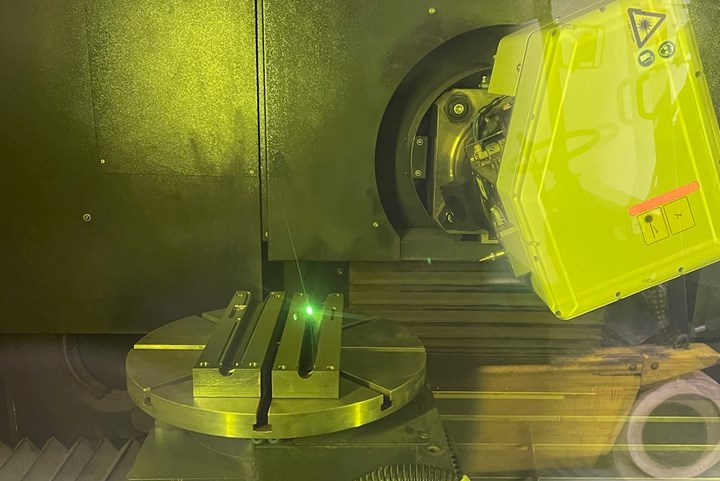

Keeping pace with the needs of the texturing industry, MST added its first five-axis GF S 1000 U laser texturing machine two years ago, enabling it to lay 3D textures on molds and rolls. The machine has a capacity of ~400 Ibs per workpiece and a working envelope of 39.4" × 21.7" × 34.6".

Beginning in Q4 2023, MST will have a second laser texture machine in operation. The GF Laser S 1200 U increases size and weight capacity nearly 10-fold, with a weight capacity of 3,700 Ibs and a working envelope of 47.2" × 35.4" × 47.2". In addition to this machine, MST has added a Keyence noncontact texture scanner, enabling the company to capture textures from molded parts and then transfer the digital information over to the laser texture machine and replicate in new tooling.

Related Content

-

Four Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.