Conformal Cooling

2024 Moldmaking Insights: A Year in Review Part 2

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

Christina Fuges

Editorial Director, MoldMaking Technology

How to Use Simulation to Achieve a High-Gloss Surface Finish

Combining simulation, conformal cooling, and a rapid heat and cooling process can predict and produce the required surface finish for high-gloss plastic parts.

Read MoreHow to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

Read MoreManifold Blocks for Flexible Cooling Circuits

Hasco’s Z920/ manifold blocks create a centralized inflow/outflow location that enables the use of shorter hoses in mold heating/cooling systems.

Read MoreA 3D Printing Retrospective

A personal review of the evolution of 3D printing in moldmaking throughout the past 25 years.

Read More3D Printing Technologies for Moldmaking Applications

3D printing technologies, from conformal cooling to complex mold building, are making an impact on the moldmaking industry, one innovation at a time.

Read MorePennsylvania Mold Builder Doubles Footprint, Maintains Quality and Company Values

Quality Mold Inc. doubles its manufacturing footprint but maintains its private company values and structure, delivering quality and fast turnaround from mold design and build through sampling.

Read MoreStrategic Mold Cooling: Optimizing Molding Quality and Cycle Efficiency

Proper cooling is crucial in molding, yet often overlooked. Discover proper cooling methods to prevent defects and improve efficiency.

Multi-Laser Powder Bed Fusion 3D Printer Supports Complex Mold Building

Using its FormUp 350 system, AddUp, in collaboration with Siebenwurst Group, improved the conformal cooling channels for a mold slide.

Read MoreVIDEO: How can 3D Printed Tooling Improve Injection Mold Venting?

Proper venting is one of a mold builders toughest challenges as molders struggle to keep vents free flowing in production. Learn how to apply 3D printing to mold venting and the benefits of additive venting inserts.

Read MoreLights-Out Metal 3D Printer Minimizes EDM Needs for Moldmakers

The Matsuura LUMEX series boasts both forming and milling capabilities in one unit, achieving highly accurate mold component production, with the ablity to integrate conformal cooling and porous venting.

Read MoreVIDEO: What Does Integrated Predictive Modeling Mean to Moldmaking

Although conformal cooling is not a new concept, new technologies have made it a very hot topic, including predictive engineering models and 3D printing. Learn about a new conformal cooling process and algorithm and what it reveals about hot spots and conformal cooling design.

Read MoreHere Are Your Top 10 Most-Read Features of 2021

A list of the most-viewed features in MoldMaking Technology from January to November 2021.

Read MoreVideos Answer Hot-Topic Moldmaking Questions

Eight questions MoldMaking Technology asks industry experts about CNC controls, the changing training landscape, the human resources and marketing keys to workforce development, predictive engineering, data, visual search, OEE monitoring and additive venting.

Read MoreAdvancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

Christina Fuges

Editorial Director, MoldMaking Technology

HTS International Optimizes Conformal Cooling with iTherm Technology

Amerimold 2021 exhibitor HTS introduces iTherm for injection molds, which can be integrated through any toolshop with various options for manufacture.

Read MoreHybrid Approach to Producing Mold Inserts Boosts Productivity and Profitability

Mold inserts with additively produced cooling circuits eliminate design constraints, reduce the cost of complexity, improve part dimensions, decrease cycle time and speed time to market.

Read MoreYudo Features Diffusion-Bonded Process for Hot Runner Manifolds

Yudo Inc. will be showcasing its diffusion-bonding process, which facilitates more design freedom for melt flow distribution, at Amerimold 2021.

Read MoreGrowing AM's Presence in Moldmaking

Advanced Michigan mold manufacturer advocates for additive manufacturing in moldmaking through collaboration and education.

Read MoreHigh-Pressure Coolant System Line Offers Machine Tool Application Flexibility

The LNS North America ChipBLASTER line has been divided into the B-, F- and V-Series, according to pressure and application for easier selection.

Read MoreHave You Heard of Printing Mold Inserts with Metal Paste?

A lower-cost 3D printing approach extrudes a metal paste to produce a mold insert with the required surface finish and tolerances.

Read MoreHow to Make Data Work for Mold Productivity and Performance

The use of digital workflows improves the impact of mold design libraries, conformal cooling and machine learning.

Christina Fuges

Editorial Director, MoldMaking Technology

Mold Components Target Route Cooling Lines

Progressive Components offers mold designers more route cooling line options within the tool with Diverting Rods, Seal Cores and O-Rings.

Read MoreMoldmaking Technology's Top-Viewed Content: Technology, Additive Tooling, Workforce Development and More

The MoldMaking Technology team has pulled together a list of the top performing items of the last month based on recent pageview analytics. Check out these great pieces on technology, cooling, hot rods, additive in moldmaking and more.

Read MoreGiving Mold Builders Additive Capabilities, Super Creativity

I saw my first 3D-printed hot runner manifold at K 2019 in Germany, but the system did not have a name yet. Fast forward to 2020 and it not only has a name, but it’s been successfully implemented in a number of applications across Europe. And today, it’s ready for the North American marketplace.

Read MoreExchangeable Drills and Tool Steel Holders For Faster Changeovers, Longer Insert life

The i-ONE line from YG-1 offers micro-grain carbide drill inserts, and premium tool steel holders with coolant channels that resist corrosion and wear and ensure body clearance.

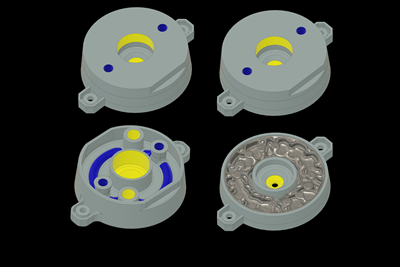

Read MoreStainless Steel Spiral Cores Issue Homogeneous Conformal Cooling

Hasco’s extended spiral core mold components in stainless steel guarantee efficient heat transfer and homogeneous core cooling for medical and cleanroom technologies.

Read MoreHow to Improve Mold Venting with Metal Additive Manufacturing

Patented 3D-printed mold insert design rapidly evacuates gases while preventing plastic flash-through, eliminates costly maintenance and need for press-side temperature-control units.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)