Latest Engineer News And Updates

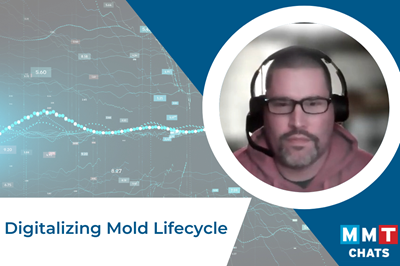

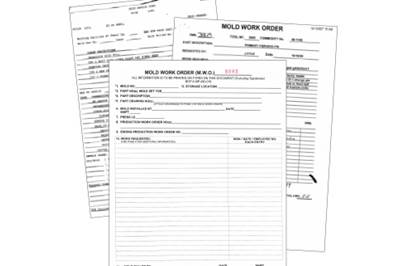

MMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.

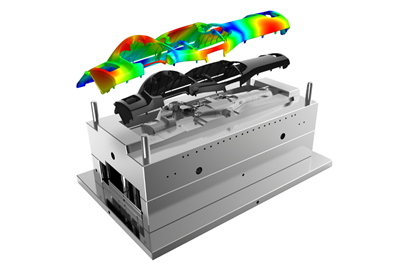

WatchHow to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

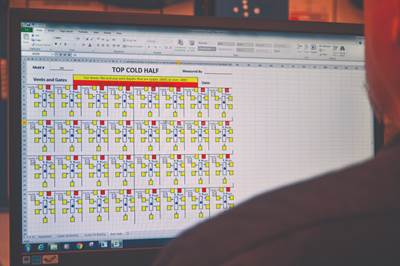

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreCustom Operating System Improves Human-Robot Interface

Unisig’s custom operating system, featured on its UNE6-2i-750-CR small-diameter gundrilling machine can reduce part setup times and improve communication between the machine’s HMI and the robotic controller.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

WatchWhat Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreFeatured Posts

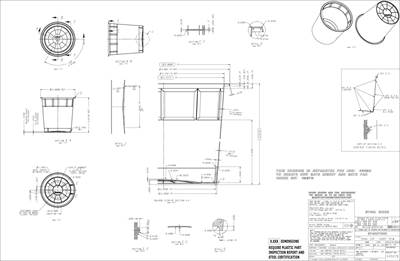

Four Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read More5 Ways to Improve Supply Chain Visibility and Efficiency

Mold builders play an important role in creating smart, connected and transparent supply chains.

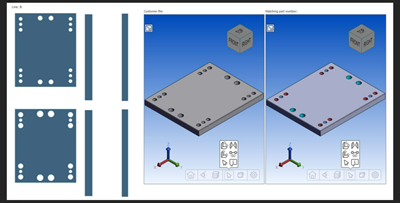

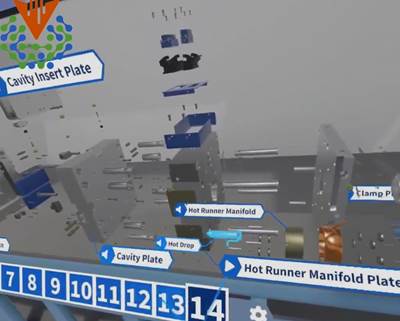

Read MoreVIDEO: Addressing Data Needs with Mold Component Solutions

The need for data to track information and the history of the mold-building process is ever-increasing, and mold component solutions can help.

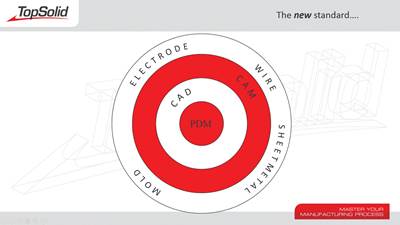

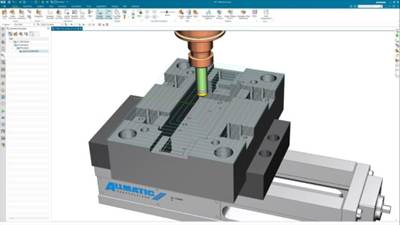

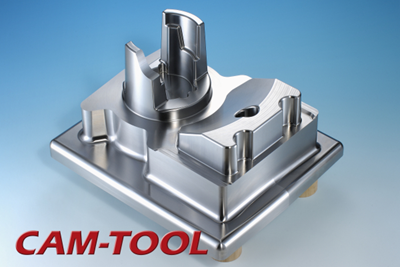

WatchIntegrated CAD/CAM Streamlines Electrode Manufacture, Improves Quality

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Read MoreVIDEO: Enhancing Data-Driven Decisions with Cloud-Based Mold Monitoring

Steps to improve data-driven decision-making and key features of a cloud-based system for mold monitoring and asset management.

WatchNavigating the Future of Mold Design and Manufacturing

What follows is a Q&A with Justin Jagels, an MMT EAB member and owner/president of J Squared Design Services LLC.

Read More