Aerospace Molds Need Proper Mix Of Application and Technology

This moldmaker flies high with a combination of specialized processes and modern technologies required for the extremely tight tolerances and exotic material concerns in the aerospace industry.

Tech Tool & Molded Plastics (Meadville, PA) has made a name for itself these past 34 years by catering to a number of industries—aerospace amongst them—with the manufacture of a variety of complex molds. This flexibility has afforded them the ability to combine technologies and processes to meet the exacting standards required in the aerospace industry like extremely tight tolerances, exotic material requirements and tooling wear.

According to Tech’s Director of Sales and Marketing Mark Hanaway, the aerospace industry is a lucrative one. “Electronics continue to play an extensive role in the efficiency, capability and safety of aerospace products,” Hanaway explains. “The rapid advance in aviation systems technology requires much more complex connectivity products and integration techniques that increase safety, increase the data that advanced warning systems require and increase the overall efficiency of the aircraft. Understanding the applications and demands of state-of-the-art systems, moldmakers with exacting machining capabilities and exotic engineering grade resin experience can carve a niche within the industry for longer term business opportunities.” Specifically for the aerospace industry, the company produces electrical connectors, assembly tools for instrument panels, electrical contacts and electrical lighting systems.

Technology, Training and Technique

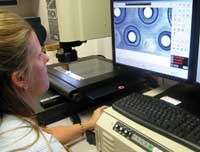

To that end, the company has developed its own complex combination of advanced technology, training and precision machining techniques to address aerospace industry concerns. Tech’s Tooling Division Manager Dale Pringle notes that the top challenges are “tight tolerances of molded product (+/- 0.02mm) and tooling (+/- .0001 in), tooling wear and material types, i.e. high glass, engineering grade materials. An example of mirror finishes would be a #12 on a Charmilles EDM.”

Tech’s Program Manager Barry Reiser expands on what the company has learned by serving the aerospace market. “The number-one challenge has been the inspection of product and the correlation of tool steel dimensions to plastic dimensions and the accuracy of conditioning—specifically using measuring systems that are non-standard in manufacturing,” Reiser explains. “Control of steel dimensions to plastics dimensions requires a robust SPC process to investigate, verify and document exacting tolerances with a SIX Sigma mentality. Trial and error techniques must be replaced with concrete data that has been verified, tested and verified again before changes in steel can be made in the grooming process. Each product feature has a specific relationship to multiples of other product features. One slight change of +/- .0001 can scrap the tool. Defining quality is only as good as the supplier and the OEM’s ability to measure it consistently, accurately and with the exact same technique. Additional issues are the management of both the primary and the secondary aspects of the projects.”

Thus, Tech used a “cross-functional team approach to problem solving with designated project management tasks at all levels of the process,” Reiser notes. “Technology alone was not the solution. Correct application of the right technology was paramount.”

Pringle explains that control was the primary concern from holding tolerances to repeatability of measurement. “When technology drives the level of sophistication of a process, controlling the level of human interaction is a critical step,” Pringle comments. “Our process was enhanced by systems of control. Although other moldmakers may have similar machining centers, controlling the process to finite levels in conjunction with the molding process has had the greatest impact. Defining a consistent method of measure in the toolroom, the plastics process, the quality lab, and the customer’s facility requires a vast amount of control of human touch points. The anthem of control is a culture that must be drilled down to scientific precision within each element of input—from design through final production. Control is based on minimizing variables and getting teams of people to perform with surgical precision.”

Lessons Learned

Often, specializing in a demanding industry results in benefits in other areas of the shop. Hanaway notes that producing molds for the aerospace industry parallels existing services to other very demanding industries. “The exposure and experience gain has furthered our understanding of measurement and exotic material processing,” Hanaway comments. “In many cases, medical products require a very similar understanding of product relationships with quality expectations, end-use environment and performance assurance similar to aerospace. Applying mission-critical precision to molded medical components has been a natural fit, which can be applied and marketed beyond current relationships.”

Catering to the aerospace industry—while challenging—is a perfect fit with the specialized services Tech Tool & Molded Plastics offers. “In industries where driving down cost is seen as the primary function to compete in the marketplace, engineers are inadvertently forced to focus with a mindset of ‘value removal’ and quality will be impacted at some stage of the process,” Hanaway says. “We recognize that cost is an element of the process, but our strategic focus is on superior product performance and repeatability of precision. Our engineers focus their mindset on performance first and foremost. As new products are developed at condensed timeframes and collaboration within the supply chain becomes even more critical for successful product launch, moldmakers can compete with responsive design and engineering services that use web-based collaboration tools such as Webex to provide on-demand answers to product performance concerns. Moldmakers that embrace technology for machining performance should consider technology for communicating with the same level of importance. If you become part of your customer’s enterprise from design through field application, you reduce the likelihood of being replaced by price.”

Hanaway advises mold manufacturers who wish to produce molds in the aerospace industry to do their homework. “Understand your process para-meters and capabilities with documented repeatability and quality assurance,” he states. “Gain a full understanding of the customer, product requirements and the requirements to produce and deliver before the program starts.”

Related Content

In "Hybrid" FIM Process, 3D Printing Complements Injection Molding

Alpine Advanced Materials used a desktop 3D printer and the freeform injection molding process to reduce prototype tooling production time and cost for its customers.

Read MoreSpeed, Productivity Gains and High Uptime Ease Decision for Second Five-Axis Machine

Byrne Tool + Design reduced setups and gained speed and productivity thanks to fast, accurate and compact five-axis CNC machining centers.

Read MoreCAD/CAM Software Reduces Delivery Times by 70% With a Six-Month ROI

Single integrated CAD/CAM package reduces translation errors, simplifies design process, improves shop efficiency and shortens tool lead times.

Read MoreCAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

Read MoreRead Next

RP/RT Technologies Offer Speed, Consistency for Consumer Products Molds

The constantly changing world of consumer products warrants molds that can be produced quickly while still maintaining high quality.

Read MoreTech Tool & Mold, Inc.: Strength and Flexibility

This moldmaker garners the 2007 Leadtime Leader Award: Small Shop by being flexible with its customers, going lean, competing globally and uniting with other moldmakers.

Read MoreElectronics Market Needs Complex Molds Fast

Meeting the stringent requirements in the electronic/electrical products market improves moldmaker’s overall processes.

Read More