Machining Outlook: Reap the Benefits of Technology Advancements Working Together

A roundtable of machine tool suppliers reviews the advancements in machining technologies that push machining and tooling to their limits—and can kick every moldmaker’s capability up a notch.

With technologies like 5-axis machining and automation gaining in popularity in the mold manufacturing industry, moldmakers are using these technologies together to reduce costs, help address the shortage of skilled labor, and make the most of their investment in machining technology—pushing both machining and tooling to their limits and optimizing their processes.

Equipment and technology offerings are becoming more refined, and manufacturers are rising to the challenge to reduce costs for mold manufacturers. Now more than ever, mold manufacturers need to get more bang for their buck and produce molds in the shortest timeframe possible. Some of today’s leading machine tool suppliers share common moldmaker questions as well as the latest in technology, and how this technology can be used to streamline the machining process.

Common Moldmaking Machining Challenges

What is the maximum spindle RPM available? What is the maximum look-ahead available for the control? What high-speed machining packages do you offer? What control variations do you offer? What memory capacity does the control have? What data transfer options are offered? Does the control have a data sever? What is the maximum cutting federate of the machine? Does your control have the ‘Auto Power off’ function? Is your machine multi-axis capable? These are just a sampling of frequently asked questions from moldmakers according to Marketing Manager David Barber at Hyundai WIA Machine America (Carlstadt, NJ).

The first question that is most commonly asked at Makino Die/Mold Technologies (Auburn Hills, MI) is regarding is tooling selection and the feed and speeds for the tooling to produce a “bench-free” finish, Greg Pozzo, VMC Application Team Leader, notes. The second most popular question is about machining the core and cavity of a mold to “net shape”—which Pozzo explains is the core to a “negative stock” and the cavity to “zero stock” to achieve minimal or no hand fitting of the parting surfaces.

According to John Ross, Marketing Manager/Sales and Marketing Team, Doosan Infracore America Corp. (Pine Brook, NJ), control capabilities are wide ranging and hard to quantify for a new user, thus leading to questions. The company spends a lot of time explaining the different capabilities and the cost of each both in time and money.

Expanding on Ross’s sentiments is Gisbert Ledvon, Business Development Manager, GF AgieCharmilles (Lincolnshire, IL). “Moldmakers often ask us how they can optimize their machining processes—making various milling, EDM and texturing processes more efficient through the use of such systems as toolchangers and pre-setting stations,” he says. “These systems allow for more unattended, lights-out operation and help increase productivity. Also, many of our moldmaking customers are still learning the limitations of high-speed 5-axis cutting. They often want to know what the right software is and cutting tools to use, as well as how should they go about preparing themselves for effectively using this technology.”

Accutex EDM/Absolute Machine Tools (Mason, OH) Vice President Pete Intihar adds that the question the company gets asked most often is if the AWT (automatic wire threader) can re-thread itself if the wire breaks.

Machining Technology Solutions

To address the aforementioned challenges, these machine tool suppliers share their thoughts and expertise on how to address them. Steve Bond, National Sales Manager, Methods Machine Tools Inc. (Sudbury, MA), notes that mold manufacturers have to use all of these technologies together to reap the utmost benefit. “Mill electrodes and have those electrodes go right into the die sinker,” he elaborates. “The mold components are staged for just-in-time machining and the products come off the machines at a completed or complete stage—all reducing handling, machine wait time and scrap.”

Marketing Manager David Barber, Hyundai WIA, notes that advanced CNC controls capable of processing greater volumes of information faster, with increased look-ahead capability are two continuing developments in machining center technology, geared toward moldmaking. “In addition, we continue to see spindle speeds increase as moldmakers look to achieve a better surface finish as well as to reduce cycle times.”

Barber also sees more and more moldmakers investing in equipment engineered specifically for the machining of molds. “While in the past a basic vertical machining center might have been purchased to machine molds; that is simply not practical today,” he says. “To remain competitive in the global marketplace, moldmakers must invest in technology better suited for moldmaking. That includes moving away from typical C-frame vertical machining centers and shifting toward bridge-type VMCs, with spindle speeds above 35,000 RPMs, thru spindle coolant—often with 5-axis capability.

“North American moldmakers are competing in a global marketplace, so any advantage that can be gained through machine tool technology is significant,” Barber continues. “Mold shops that are investing in state-of-the-art machines, engineered specifically for moldmaking are the ones benefiting the most from work that is coming back on shore, for domestic production.”

Both Hyundai WIA and Doosan have designed machines specifically tailored to the moldmaking industry, engineered for the machining of precision molds and simultaneous 5-axis machining (Hyundai WIA) and machines developed with heavy construction and vibration absorbing box ways, giving a solid foundation to build a machine to suit any requirement (Doosan).

Doosan Infracore’s Ross notes that bigger spindles with dual contact—although not new—are finally becoming more widely accepted. “The tool’s increased rigidity allows both heavier cuts with short tools and less chatter when you need tools with a long reach,” he notes. “This will bring every moldmaker’s capability up a notch.”

Another trend is increased control speeds, Ross notes. “It is not uncommon to get 1000 block and higher look ahead capability with tolerance control—pushing both the machine and tooling to their limits,” he notes.

Additionally, CAD/CAM software is getting very close to being completely integrated to the machine with very realistic simulations. Testing programs can be done without risk of damage to machine, tooling or parts, according to Ross.

Expanding on the CAD/CAM trend is Accutex EDM/Absolute Machine Tools’ Intihar, who says the company plans to add projecting to add 3-D CAM software, which will allow the moldmaker/EDM operator the ability to see their part in solids on the machine, as well as adding more tech files, which will allow the operator to store specific files and settings to save time in the future—the next time the job needs to be performed. Plus, the operator will be able to call up to relate to another similar job.

According Ledvon of GF AgieCharmilles, the machining advancements in 2012 will allow moldmakers to keep better tabs on their processes and further streamline their efforts—all for the sake of improving accuracy, productivity and profits. “In terms of EDM, the machines will incorporate more process inspection features so that moldmakers or mold designers can inspect their parts during and in-between each individual machining operation for maximum accuracy,” he elaborates. “As a result, the inspection process no longer has to take place after the part is already completed and removed from the machine.”

In terms of milling, Ledvon anticipates 5-axis, high-speed milling becoming even more precise and further advanced through machine-integrated automation. “Such innovations in automation will continue to play key roles in helping the industry deal with the skilled labor shortage,” he says. “Additionally, I foresee optical rather than laser measurement being incorporated into machines a lot more for accurately presetting and inspecting cutting tools.”

GF Agie’s Ledvon points to the following trends in machining technology developments: process inspection, better textures and surface finishes, enhanced automation and increased process monitoring. He notes that the company will continue to focus on many of these technology developments when designing and building its new wire and die-sinking EDMs and 5-axis milling equipment.

Pozzo of Makino also reports notable advancements in milling machines. “The thermal stability of the machine tool is critical to the die/mold process,” he states. “This is due to the nature of die/mold where many of the toolpaths are continuous 3-D motion over very long periods of time where the spindle is being run at very high RPM and all of the machine’s axes are being driven at very high feedrates—along very complex shapes—where the machine will be accelerating and de-accelerating continuously. These conditions on most machines would generate excessive heat and allow for thermal growth of the spindle and ball screws—thereby changing the accuracy of the part being machined.”

There is spindle technology designed with these challenges in mind—core cooled under race lubrication spindles, Pozzo notes. “By cooling through the center of the spindle where the heat is being created the problem at the core is eliminated. Under race lubrication is designed to lubricate the bearing from the center of the spindle out. This design is a better approach as it works with centrifugal force to lubricate and cool instead of trying to lubricate from the outside in as most other high speed spindle designs. By controlling the temperature of the spindle the bearings can be preloaded allowing for a more rigid spindle for hard milling of 60+ Rockwell Materials.”

Additionally, Pozzo says that core cooling the ballscrews and cooling the ballscrew housings will also stabilize any fluctuation in temperature due to consistent change in direction of the axis for mold applications. Heat can also be generated along the boxways of the machine. This component is also core cooled to stabilize temperature.

“The net effect of these technologies allows the machine to be volumetrically more accurate over long periods of time allowing the machining of mold components to zero stock, with bench-free surface finishes,” Pozzo says.

Another advancement, automatic calibration of the machine for different weights of parts, allows for the tuning of the axis based on the load of the feedback of the servo motor, Pozzo explains. “This allows the machine to calibrate the acceleration and deceleration parameters based on the weight of the part and will more ‘finely’ tune the machine for accuracy for the part.

Advancements in EDM technology at Makino include an anti-rust wire EDM unit that eliminates rust on tool steels during operation without the need for costly water additives—saving the moldmaker many labor man hours of cleaning rust off the workpiece and possible repolishing performed after wire EDM; a rib machining process that can reduce rough machining speeds up to 34 percent by using operator inputs to automatically determine the most efficient power setting based on electrode reduction, draft angle, and detail depth; and a sinker technology designed to prevent destructive arcing from happening under the most difficult EDM applications. According to Pozzo, this safety technology provides the operator with a highly sensitive adaptive power control, and is especially useful at the start of machining when there might be minimal frontal contact between the electrode and workpiece.

Intihar of Accutex/Absolute Machine notes that three-pass technology, which reduces the number of passes required to achieve the surface finish and accuracies that normally took additional passes, will save time, conserve energy and reduce wire consumption costs.

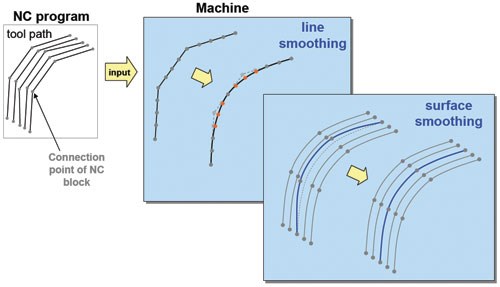

To accommodate manufacturers of large molds, Makino has developed a new control technology, which Pozzo explains helps improve surface finish and machining time. “Due to the sheer size of large molds and their complexity, in many cases the NC programmer will increase the toolpath tolerance to reduce memory usage and calculation time on finish toolpaths,” Pozzo says. “The net effect on the machine is a toolpath that is not as closely defined to the actual model and large spacing between toolpath points. Due to these conditions the control cannot perform at the peak performance and the surface finish of the part is not optimal.

“The new control technology will analyze the toolpath points and will redistribute them to more closely align the points to the feature shape and in a more efficient manner to allow faster processing of the toolpath,” Pozzo continues. “This process is not simply ‘smoothing’ the toolpath segments, but rather analyzing the whole toolpath topology and re-aligning based on this analysis.” (See Figure 1)

Summary

Advancements in machining technology will benefit the mold manufacturing industry as a whole. “Overall, I believe the moldmaking industry will see more automation, flexibility and technology driven by customer applications,” GF AgieCharmilles’ Ledvon notes.

The year 2012 promises to be an exciting one in the arena of machining technology as manufacturers prepare for IMTS and continue to roll out the latest in CNC controls, faster spindles, process inspection features, and equipment specifically tailored to the mold manufacturing industry.

Related Content

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreAdvantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)