Achieve More with Twin Wire EDM Technology

As wire costs continue to increase, twin wire will be recognized as a strong tool for fine tuning wire EDM performance and reducing cost.

Most, if not all mold shops are under ever constant pressure to reduce operating costs and improve turnaround time to compete in the global market. This is no surprise; we have been fighting this war for some time now. One thing that may or may not be apparent to those on the front line is the effort that machine tool manu-facturers take to help make their products more productive and economical. There are many different approaches EDM manufacturers now take to reduce operating costs. Some main areas of focus include:

- Improving electrical and EDM generator efficiency to reduce overall power consumption.

- Re-developing erosion technology with an emphasis on slower wire feedrates.

- Increasing precision in the roughing cuts to reduce trim passes.

- Increasing cutting speeds and precision of smaller diameter brass EDM wires to the point where they can replace larger diameter wires in many applications.

These enhancements are all valuable, but there are other opportunities to save cost.

For instance, what if we looked at a wire EDM like we look at a machining center? What if we could automatically change from a roughing wire to a finishing wire? Being able to change wire automatically has merit in more than a few applications.

The following applications represent four different scenarios that present additional cost savings opportunities:

Application 1

Small Radii Requirements

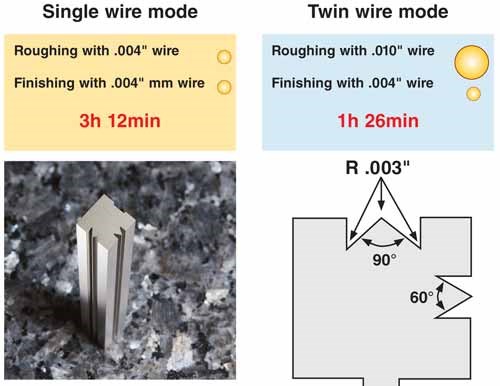

The most common use for twin wire EDM systems is the ability to erode contours with small inside radii using a larger wire diameter first, then auto-matically change to a smaller diameter wire, perform the finish passes and complete the smaller radii (see Figure 1).

In Figure 2, the cost benefits associated with using this strategy become apparent. Without the benefit of twin wire, this part would most often be cut completely with .004" diameter wire, since it would be too costly and cumbersome to switch wire diameters on conventional wire EDM machines.

Application 2

Multiple Contours with Varying Requirements

Many components require that the inside shapes and the outside perimeter be machined with wire EDM. Figure 3 represents an application where the inside details have smaller radii requirements that the outside detail. On conventional EDM machines, there are at least two ways of approaching this job:

- Complete the outer contour and the inner contours with the smaller diameter wire.

- Cut the inner contours with the smaller diameter wire, manually change wire to a larger diameter, and complete the outer contour. This process may achieve a faster cutting time, but that time savings may be lost due to costs associated with the wire changeover. On most EDM machines, this changeover can be a timely process requiring the actual changing and re-alignment of the wire guides.

On a twin wire EDM machine, the job can be approached in an entirely different manner:

- If small enough, the inner contours can be no-core cut with the larger diameter wire first. Otherwise there would have to be an intervention for slug removal.

- The twin wire system will then automatically change over to the smaller diameter wire and perform the finish cut on the inner contours.

- The twin wire system will then automatically switch back to the larger diameter wire and complete the outside perimeter of the component.

It should be noted that in a situation where high accuracy details are going to be finished with two different diameter wires, the operator may want to verify the position of each wire prior to erosion. This is mainly due to the slight manufacturing variations in the wire itself.

It also should be noted that in larger components, it may be necessary to rough out the outer perimeter prior to completing the inner profile. This strategy would be used if there is a concern about part movement during erosion.

Application 3

Using the Best Wire for the Task

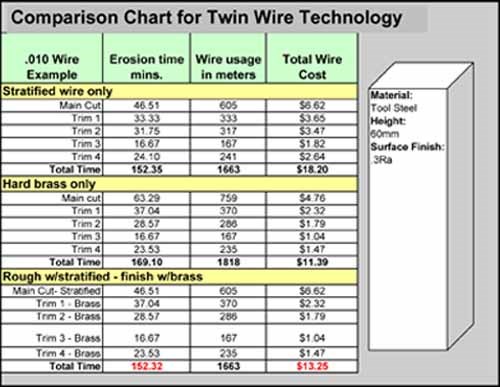

As the cost of wire continues to increase, this strategy becomes more relevant. With twin wire EDM systems, it becomes an easy matter to use high-performance stratified wires for the roughing pass, and then automatically change over to economical brass wire for the finishing passes. This combination allows the user to take full advantage of the high-speed capability of stratified wire in the rough cut without wasting the high priced wire on the successive finish cuts.

Table 1 compares three different strate-gies for cutting the same piece of 60mm tool steel with high accuracy and surface finish requirements. The cost savings of using two different types of .010" diameter wire for this application is apparent.

Application 4

Superfine Surface Finish Requirements

Some twin wire EDM systems are capable of achieving surface finishes as low as .05 Ra µm. In order to obtain such finishes, a high quality zinc coated wire should be used. This high quality .008" zinc-coated wire can be up to 60 percent more expensive than brass, and does not provide a real advantage in cutting speed. With this scenario, it may pay to actually rough with brass wire, and finish with the zinc-coated wire.

This is an unusual reversal in the world of wire EDM. The emphasis on technology development for economical brass wire has opened up a new world of possibilities that will allow brass wire to operate at much the same speeds as a zinc-coated wire in many applications (see Figure 4).

Summary

The automatic wire changing capabilities of twin wire EDM systems are well suited for any multi-diameter wire application. As wire costs continue to increase, they also will be recognized as a strong tool for fine tuning wire EDM performance and reducing cost.

Although twin wire technology has been well embraced by the precision die-making community, it is only in its infancy in precision moldmaking applications. As the pressure continues to use more cost-effective EDM techniques, the more likely we are to use it in the future.

References

1FI 2050TW.

2AC Vertex 1.

Related Content

Integrated CAD/CAM Streamlines Electrode Manufacture, Improves Quality

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Read MoreMMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreCollaborative Engineering Drives Quality Mold Solutions

Advanced engineering and tooling teams collaborate to train, design, develop and deliver high-quality, cost-effective molds efficiently, ensuring perfect parts and faster launches.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreRead Next

Burning Bright

EDM experts reveal that trends in increased automation combined with unattended machining result in better accuracy and surface finishes in wire and diesinking EDM applications.

Read MoreTips on Improving Wire EDM Productivity

By focusing on such aspects as maintenance, tooling and training, moldmakers can increase the productivity of their wire EDM significantly.

Read MoreWear Parts and Consumables: The Keys to Maximizing Your EDM

Mold shops need to pay attention to the potential impact wear parts and consumables can have on their overall production.

Read More