Burning Bright

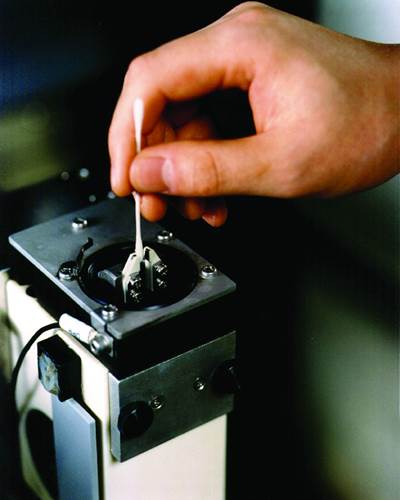

EDM experts reveal that trends in increased automation combined with unattended machining result in better accuracy and surface finishes in wire and diesinking EDM applications.

When looking for ways to stay competitive, look no further than the EDM department. Investing strategically in EDM machinery and technology can improve accuracies and surface finishes and reduce cycle times. Our roundtable of EDM experts share the latest advancements in EDM technology, the number of challenges moldmakers face when using EDM equipment, and suggest ways to tackle these challenges.

1. What major advancements to you foresee in EDM this year? And how will these advancements affect the moldmaker, mold designer and the moldmaking process in general?

Glynn Fletcher, President, Agie Ltd. (Lincolnshire, IL): High-speed milling is capable of forming many of the contours that would once have been machined with die-sinking EDM. Today, EDM systems’ capabilities are being honed to burn deep ribs and very small, intricate details that require fine surface finishes in locations that are difficult or impossible to polish.

In both die-sinking and wirecut EDM, automation is an ongoing trend, bred in the necessity to become more and more productive. Advanced technology is where EDM is heading—and indeed must head—if we are to compete successfully on a global basis.

Gisbert Ledvon, Marketing Manager, Charmilles Mikron U.S. (Lincolnshire, IL): I see better accuracy and surface finishes for wire and diesinking EDM as well as more small wire (e.g. 0.001” or smaller) applications. This is critical for moldmakers who want to get into more advanced applications—in other words, parts that cannot be made in low-cost labor countries (e.g. FDA-approved medical components). More use of the twin wire technology will reduce operating cost and increase autonomy. This will help moldmakers to make very intricate parts in a very efficient way. Until now moldmakers were forced to use small wire (very slow cutting speed) for the entire cut if the inside corners or details of a mold insert or even EDM electrodes, or they had to manually switch from a large diameter wire to a small diameter wire to cut the part faster. The twin wire technology allows the user to rough cut (max. cutting speed) with a large diameter wire, then the machine automatically switches to the smaller diameter wire and finishes the part unattended.

We also will see advancements in filtration for wire EDM to run unattended longer. This is specifically important for the high-speed cutting generators that are producing more parts per hour now. Larger integrated filter capacity and new filter designs will reduce downtime of the wire EDM and reduce operating cost significantly. One other item is larger workpiece capacity—specifically for wire EDM in the mold shop. In other words, the moldmaker of today needs to be flexible and so should his EDM. If his new EDM can handle heavy workpieces and cut large taper with 30 degrees in tall parts (15"-20"), he has a good chance to get more domestic jobs, because it is unlikely that companies are shipping large molds overseas by steadily increasing shipping cost and rising oil prices.

New developments in five-axis wire EDM’ing—or as we call it turn and burn—will open up new opportunities of designing complex 3-D mold components and cutting them unattended, cost-effectively and precisely in one setup. This technology will open up new markets for moldmakers like medical components.

Bud Guitrau, president E & M Engineering, Inc. (Placentia, CA): Any new improvements to EDM productivity appear to be in external forms—in tooling and automation or in high-speed milling of electrodes—and not so much in EDM itself. Today’s EDM equipment is incredibly capable. I believe the machines themselves are already approaching their practical limits in speed, accuracy and finish; and therefore, are difficult to improve upon. The current focus of moldmakers on their EDM operations is on ways to make their existing equipment more efficient. For example, instead of running three machines on a one-shift workday, the better choice would be to run one machine in a three-shift workday. Continuing with this example, the integration of robotic tool and workchangers can allow an unattended, lights-out operation of the additional two shifts rather than the hiring of two more operators—which would significantly increase fixed overhead. With many machines running at only 30 to 50 percent capacity, moldmakers are actively exploring every avenue to increase productivity while reducing costs.

Mark Rentschler, Marketing Manager, Makino (Mason, OH): The next major advancements for EDM will focus on miniature and micromachining with technology to address the small spark gap required for most applications in this area. This also may lead to new and improved products from EDM materials manufacturers (electrodes and wire) to address the requirements of this growing field. Also, global competition will encourage even more moldmakers to consider automation, work cells with robotics and palletization of work on both RAM and wire EDMs. Moldmakers will continue to expand the role of high-performance milling and focus EDM use on hard-to-reach details.

Mike Altergott, Regional EDM Sales Manager, Mitsubishi EDM (Wood Dale, IL): Automation, unattended operation and new technology are the trends really advancing the EDM industry right now. Faster cutting times, better finishes and more accuracy will be essential and pivotal in the upcoming years. The speed at which moldmakers adapt to the new technology and trends will determine their overall success and longevity in the industry.

2. What common challenges do mold-makers face with EDM today and what are some recommended solutions?

Fletcher, Agie: Moldmakers are under relentless pressure to produce products with closer tolerances in less time at lower cost. Palletized tooling and automation are increasingly vital, both on the Z-axis RAM and on the worktable as well, so that both the electrode and workpiece are accurately positioned with repeatability in the range of 0.0001". Both types of tooling

can be served by a robot that changes the electrodes and workpieces, enhancing productivity still further.

Finally, understanding and optimizing the use of the advanced orbit patterns that die-sinkers are capable of is yet another means of differentiating an advanced EDM capability from the garden variety, oftentimes offshore, mold shop.

Ledvon, Charmilles Mikron U.S.: Competition is getting tougher and customers are demanding faster turn-around times. Thus, moldmakers will need to automate to stay competitive. Some of them believe that they should jump into automation right away and buy all the bells and whistles like a robot, a chip reader or cell management software for big money. But, when the automation cell is installed, some of the users are overwhelmed with learning the function of the cell and organize their work so the robot and the machine are running all the time. At that point, the expected ROI will be disappointing. That is why we developed a step-by-step automation transition with automation software that can grow with the customer’s experience. It organizes the job flow by transferring electrode offsets and workpiece locations from a CMM or preset station into the CNC of the EDM. This will help the moldmaker to organize his work and maximize sparking hours on his EDM, utilize tooling for electrodes and pallets for workpieces, and minimize or eliminate setup time on his EDM.

Guitrau, E & M Engineering: The most common challenges are a) the growing amount of mold work being outsourced and b) finding ways to increase their productivity—while reducing costs—in order to protect their remaining market. I believe that these points are not merely the most common challenges to American moldmaking, I’d say they are universal and integral to all of American manufacturing. The solution? See “b”, as “a” will only continue to increase. Many larger firms have the luxury of option “a”, having the resources and ability to place all or part of their operations offshore. Unfortunately, the backbone of American moldmaking—the smaller and independent mold shops—don’t have this option and must exercise “b” to survive in today’s manufacturing economy.

Unfortunately, this is less a problem than it is a condition. American manufacturing is approaching a condition called de-industrialization. This is a normal and natural occurrence in any industrialized nation’s timeline when domestic manufacturing costs rise to a point that make profitable competition with emerging nations more and more difficult. Study the market. See how the jobs are moving and then follow the money. Today’s SIC codes are much more fluid than in the past and need to be watched closely as more and more of the less technical and low accuracy jobs are being outsourced everyday. I’d suggest pursuing molds, tooling and parts for the medical industry and high precision electronic applications. Also, military and defense projects are typically long running and are not likely to be exported for obvious reasons.

I see many mold shops diversifying into other job disciplines. More and more production part making and other kinds of tooling are being integrated into mold shops to broaden their base and replace the mold work that is decreasing or becoming less profitable. This vision and ability to adapt and change is healthy, especially when it becomes necessary. Agility in manufacturing is absolutely essential these days.

Rentschler, Makino: The common challenge faced by all moldmakers today is offshore global competition and use of cheap labor to produce the tools and molds. In order to survive, some recommendations include improving customer service, reducing leadtimes and improving quality—all by using the newest machining technologies that will improve surface finish on RAM EDM parts and eliminate bench work and shorten leadtimes. Strategic investment in the latest wire EDM technologies that cut faster and improve part straightness, corner accuracy and surface finishes also will reduce wire consumption and therefore reduce costs. Hard milling capabilities will reduce cycle times, and improve accuracies and surface finishes, and change processes will permit North American mold builders competitive advantages to serve their customers better. The use of automation in workpiece electrode management and storage combined with lean manufacturing principles like waste elimination, continuous improvement, Just-In-Time manufacturing, visual management and quick changeover techniques also will insure timely delivery and improved performance and quality while reducing costs.

Altergott, Mitsubishi EDM: The need for accuracy, finishes and repeatability are the biggest challenges moldmakers deal with. Electrode accuracy is incredibly important for high productivity and good product finishes. If an electrode is off by only 0.2", it will cause metal removal on one side of the cavity to work harder, leading to excessive burn time on the other side. Therefore, electrode manufacturing with better accuracy will help increase productivity and decrease burn times.

Taking advantage of the latest EDM technology will allow you to remain competitive while improving surface finishes and accuracy—in addition to reducing cycle times in your shop.

Related Content

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreFive-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreRead Next

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More