New, five-Axis Laser Texturing System Offers Speed, Accuracy and More Geometric Options

Attendees at GF Machining Solutions’ unveiling of Laser S series say they are excited, impressed with speed and accuracy of mold texturing system.

Share

Read Next

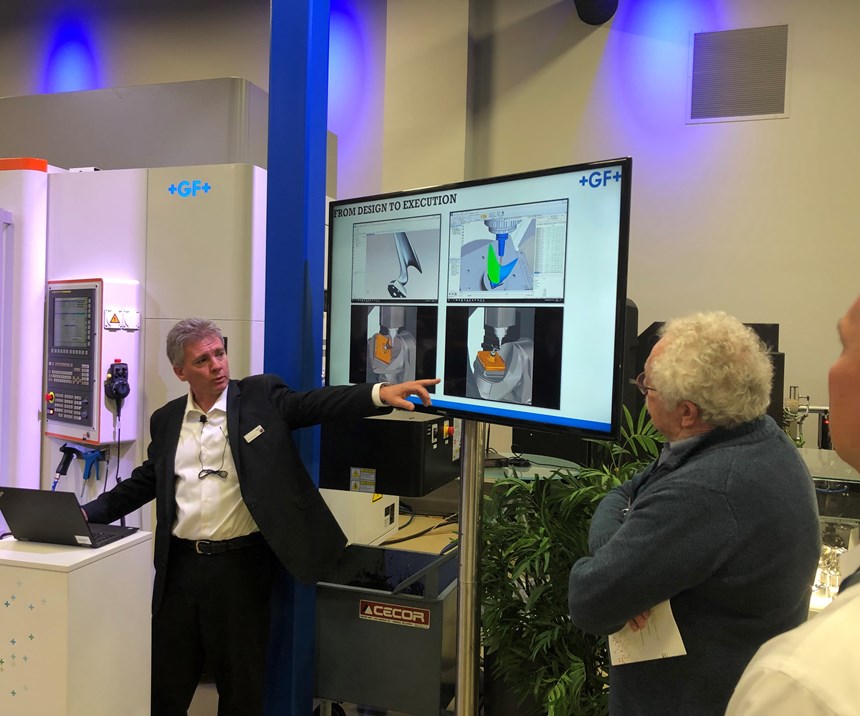

GF Machining Solutions unveiled the new AgieCharmilles Laser S series, a digital, all-in-one, five-axis laser texturing system for molds, at a special press event held in its Center of Competence showroom in Lincolnshire, Illinois. The company introduced its Laser P series 10 years ago. While the Laser P series is still a viable product line for mold texturing, Yvan Meyer, head of Laser Texturing at GF Machining Solutions, says it is more of an entry-level system now, with the Laser S series offering more advanced features including its ability to perform laser blasting, structuring, engraving, machining, texturing and marking, all in one system.

GF Machining Solutions sees this new, advanced laser texturing system as one that will add functionalities to surfaces for medical OEMs looking to reduce risk and product cost per part (the company says that it sees “explosive potential” in dental and orthopedic implants), and enable new designs and shortened lead times for packaging, cosmetics and kitchenware OEMs who are also watching costs but seek product design innovation. The information and communication technology (ITC) OEMs can also benefit by now having the ability to achieve finer textures and increased quality on such items as laptops and smartphones, where aesthetics counts.

Impressive Laser Capabilities

Attendees at the recent unveiling of the Laser S technology say they are excited and impressed by the new capabilities offered. Don Melonio, vice president of Custom Etch Inc. (New Castle, Pennsylvania), says the new L1000 S machine “is a giant leap forward in laser technology.” He explained that Custom Etch bought the first GF Machining Solutions laser system sold in North America in 2011 and, since that time, the company has added a new system each year. All the machines run 24/7, 365 days a year, and an order has already been placed for an L1000 S. “I’m impressed by the Dynamic Z feature in the new laser head design. It is the single biggest improvement to the previous machine versions because it will allow for dramatic improvements in speed and quality. The patch size is now optimized with Dynamic Z, thereby reducing the number of patches needed as well as reducing machine movements and process time,” he says.

GF Machining Solutions did introduce new software, like Smartpatch, which allows examination of the pattern before it is laser machined onto the mold, and Smartscan 3D, which provides UV mapping for texture applications and 3D simulation to optimize every patch that is machined, was developed to further ensure that both efficiency and quality are achieved, the company says.

Customers are pushing the envelope when it comes to accurate, unique grains.

Another long-term laser texturing customer, John Seiberlich, president of St. Paul Engraving (Stacy, Minnesota), says the laser machines are always impressive, but he is just as enthralled by how GF Machining Solutions works with customers to understand how they use the technology and what improvements are needed. “The Laser S features improvements (over the Laser P series) are based on most of what we told them,” he says. His company currently uses the AgieCharmilles Laser P 1000 U and 1200 U. He says the machines have benefited his customers by enabling better precision and faster process times over conventional acid etching. “With the five-axis laser technology, it has added the 3D aspect of texturing which cannot be done using conventional texturing methods. It has also helped to minimize the use of the film process.”

Pete Kambouris, vice president of Wisconsin Engraving Company (New Berlin, Wisconsin), says his company has been using the Laser P series for about six years now and last November, they brought one in house. After seeing the Laser S series, he is very impressed with the speed and accuracy with which it can work on contoured surfaces. “Customers are pushing the envelope when it comes to accurate, unique grains,” he says. “The automotive and packaging industries want to stand out cosmetically, and the electronics industry needs consistent finishes across huge tooling programs. One of our customers builds so many tools a year that the laser is the only way surface finishes will match from tool to tool. They have very strict appearance tolerances that must be met. They use mold manufacturers all over the world and each vendor chooses its own supplier for applying texture. Traditional methods are not accurate enough to be as consistent as our customer would like.” Before purchasing its Laser P series, Wisconsin Engraving did not have five-axis capabilities in house. “Now we have to find room to add more lasers!” he says.

Other innovations noted by GF Machining Solutions include increased machine stability, which uses thermostabilization to prevent movement of the laser beam spot throughout the machining process. A larger marking field helps boost productivity; two laser heads make it easy to switch wattage levels and move on quickly to another job; and the 30-watt Flexipulse laser enables operators to achieve very finely-detailed, high-quality results.

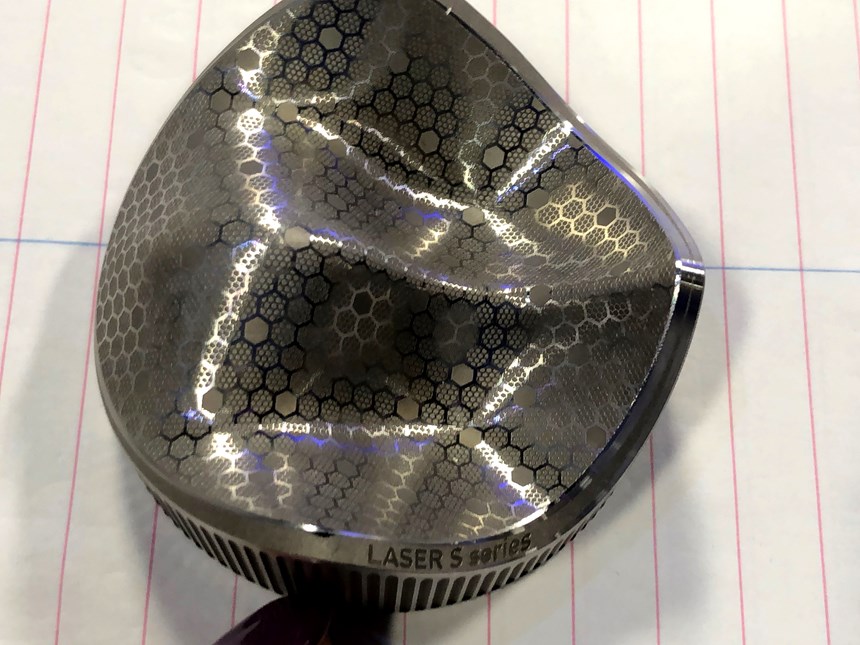

Delivering Optimized Geometrical Patterns

All three gentlemen agree that the demand for complex textures including more geometric patterns is on the rise, and that GF Machining Solutions’ Laser S series is answering the call. “Many of the new, complex geometric designs are not achievable using manual chemical methods,” Custom Etch’s Melonio says. “The laser systems are giving designers a broad spectrum of patterns not previously attainable.”

The laser systems are giving designers a broad spectrum of patterns not previously attainable.

St. Paul’s Seiberlich agrees. “The consumer goods industry, outdoor recreation, automotive, recreational vehicles like motorcycles, snowmobiles, ATV’s and so on, are all looking to establish more geometrical shapes and patterns on their products, and these are difficult to apply by film because of the risk of overlap and distortion,” he says. “The software that is used with the Laser S series will wrap and generate the patterns on 3D surfaces per the suppled CAD model, creating very little manipulation of the pattern that most eyes will not pick up on. This also makes it possible to match these patterns with mating components, which is nearly impossible to do with the conventional method.”

Asked whether laser etching will ever completely replace chemical etching, all three gentlemen agreed that both have their place in mold texturing – at least for now. “There will always be a need for chemical etching,” Wisconsin Engraving’s Kambouris says. “Not all customers require what the laser provides. The customers we use the lasers for require tighter tolerances, increased repeatability, unique designs and the ability to replicate these designs globally.”

Melonio is a little more optimistic about laser texturing’s future at Custom Etch. “While I personally feel that there will always be a need for the chemical or manual process, I can see a day where the majority of our work is processed either fully or partially by the lasers.”

Related Content

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreLine Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreRead Next

2018 Technology Review and Sourcing Guide: Mold Maintenance, Repair & Surface Treatment

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including mold maintenance, repair & surface treatment.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More