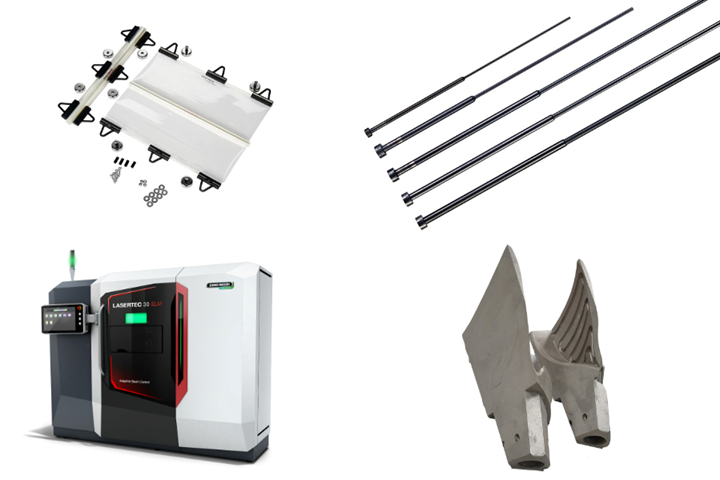

Photo Credit, clockwise from top left: PCS Company, Hasco, AddUp and DMG MORI

As we head into the halfway mark of 2023, MoldMaking Technology staff continue to curate a list of relevant technologies in the form of roundups for readers to get a glimpse of what’s new and what’s improved. Tech roundups are a great way to stay informed on innovations hitting the market, or even to discover your next equipment investment to take your shop to the next level.

This month’s roundup features products, processes and services involved with additive manufacturing, maintenance and repair, mold components and more. To learn more about the products, read on.

To get an even bigger picture of tech on the market, check the “New Tech” section of the MMT website, where new posts are published daily. For more information on an item featured below, click the title link attached to each respective product, or visit that company’s website.

Photo Credit: Progressive Components

Slide Components Can Run Greaseless, Provide New Side Actions

Progressive Components has introduced new gibs, center guides and wear strips to its Slide Component product line. Each side-action component features Progressive’s Z-Series black-nitride finish and particle-ring combination. The items are available as blanks, with pre-machined counterbores for screws, and they are designed to be cut to length for customization for each unique application.

Photo Credit: Progressive Components

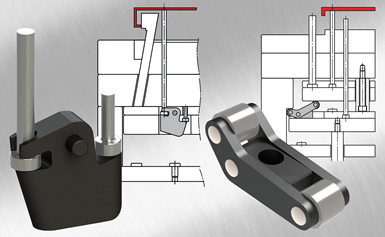

Mold Ejector Accelerators Achieve Second-Stage Ejection

Progressive Components has introduced Ejector Accelerators, featuring a compact footprint that’s sized for inch ejector pins and ejector plates. The product is designed to create a second-stage ejection without the need for a second set of ejector plates. Actuating an ejector pin forward movement, the product can be used when additional pin travel is required to release a molded part from lifters, stripper plates or deep core features.

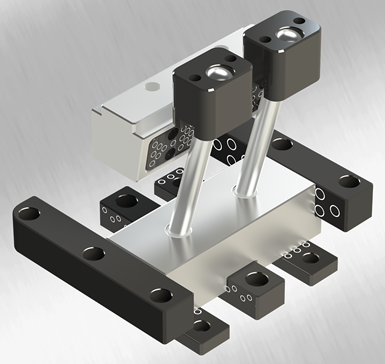

Photo Credit: Progressive Components

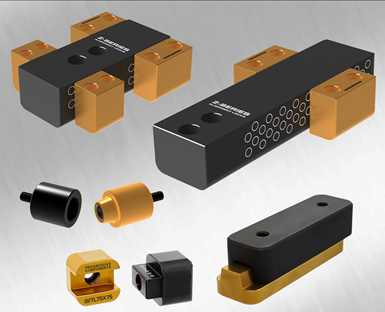

New Alignment Options Machined From Parting Line

Progressive Components has further expands its Z-Series Alignment Lock product line with the introduction of several new options for easier mold manufacturing. Designed to be machined from the top at the parting line, new Top Machine Style Bar Locks simplify machining steps and increase pocket accuracy by enabling the alignment pockets to be machined on the same setup as cavity and core plate pockets. For multi-parting line tools, Progressive has also added an X-Style Bar Lock configuration. Both Top Machine and X-Style Bars are available in 3 sizes to pair with corresponding Guides.

Photo Credit: MC Machinery

Wire-Laser Metal 3D Printer for Efficient, Versatile Processing

MC Machinery Systems’ Mitsubishi AZ600 wire-laser metal 3D printer melts welding wire with a laser beam to create high-quality 3D structures, producing high-speed, high-precision 3D printing while reducing energy consumption and waste. The printer applications include rapid prototyping, mold and die, one-offs, short runs, mass manufacturing, maintenance, repair, tooling and more.

Photo Credit: AddUp

Shaping Steel Enables More Complex, Efficient Injection Molds

AddUp Inc.’s shaping AISI 420 steel is commonly used in the field of plastic injection and can now be used for additive manufacturing (AM). The company says AISI 420 steel can enable tooling manufacturers to develop new, more complex and more efficient molds. The material is now available for all FormUp 350 new generation powder bed fusion (PBF) machines.

Photo Credit: Nikon Metrology

Noncontact Laser Scanner Enhanced for Mold Inspection Suitability

The LC15Dx laser scanner manufactured by the Industrial Metrology Business Unit of Nikon Metrology is a global benchmark for efficient measurement and inspection of manufactured components, especially those with complex freeform geometry. Compatible for use with all metrology platforms and software, a new version of the sensor has been launched to make it more suitable for quality 4.0 inspection applications.

Photo Credit: Shining 3D

Dual-Mode Metrology Scanner for Accurate Mold Measuring

Shining 3D, a global provider of technologies for 3D digitization and 3D inspection, expands its FreeScan UE series of metrology 3D scanners with the FreeScan Combo. Increasingly, noncontact 3D inspection has become a go-to method for moldmakers as free-form surfaces increase and the precision requirements for mold processing rise.

Photo Credit: PCS Company

Mold Lifting Rings Offer Efficient Mold and Die Management

The Codipro Mold Lifting Rings from PCS Company are said to provide moldmakers and molders with more efficient material handling and moving of molds and dies. Codipro hoist rings and eyebolts swivel, and are available with simple, double or triple articulation, giving users the ability to move molds and dies in all directions and positions as needed.

Photo Credit: Globeius Inc.

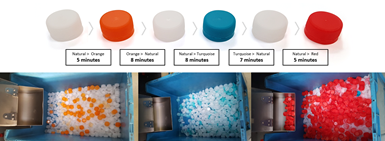

Hot Tip Sprue Cleaner Melts Obstructive Plastic

Hot sprue bushing and nozzle tips are critical components that often require care during preventative maintenance and are costly in terms of replacement and downtime when clogged. Globeius Inc.’s Hot Tip Sprue Cleaner brings sprues and nozzles back to production-ready life, quickly and safely, offering a fast and convenient way to eliminate those clogs, in some cases without the need to remove the mold from the press.

Photo Credit: GF Machining Solutions

High-Precision VMC With Unrestricted Five-Axis Machining

GF Machining Solutions highlights the Mikron Mill S 200 U, a vertical high-speed machining center with unrestricted five-axis machining capability, which is the result of its table design that provides interference-free part access. The machine is said to be designed for the highest precision and surface quality and is well suited for tool and moldmaking and other high-precision parts production.

Studer S100 (top left), Blohm Profimat (top right), Studer S36 (bottom left), Walter Helitronic Mini Plus (bottom middle) and Walter G200 (bottom right). Photo Credit: United Grinding North America

Grinding Equipment Realize Strong Productivity Gains for Moldmakers

United Grinding North America announces the expansion of its extensive range of grinding and measuring equipment with seven new products being unveiled by three of the company’s brands, Studer, Blohm and Walter. Studer has brought two new cylindrical grinding machines with the release of the S100 and S36. Blohm continues its tradition of customer-centric surface and profile grinding innovation with the release of the Planomat XT Essential. Walter is focused on packing more tool grinding functionality into a compact space with the Helitronic G200 and Helitronic Mini Plus.

Photo Credit: Walter USA

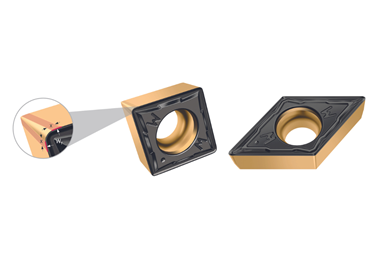

Positive Wiper Geometries Increase Productivity, Part Quality

With the FW4 and MW4 positive wiper geometries, Walter USA is introducing two indexable insert geometries for longitudinal turning and facing that combine the “wiper effect” and the new highly wear-resistant Walter Tiger·tec Gold grades. The curved wiper cutting edge is a feature that makes the wiper action universal across various material groups such as steels, stainless steels, cast irons or even super alloys.

Photo Credit: Walter USA

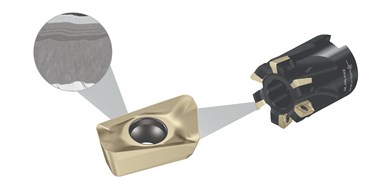

Multilayer Insert Grade Mills Difficult Mold Steels

Walter USA is expanding its Tiger·tec Gold cutting tool insert range with the new WSM35G milling grade. The indexable insert is coated with a PVD Al2O3 coating technology with a multilayer structure on a carbide substrate. The structure consists of a bottom TiAlN layer for high wear resistance, a middle Al2O3 layer for high temperature resistance and a ZrN gold-colored top layer for minimized friction and optimal wear detection.

Mitsubishi SG12 sinker EDM (top left), MV2400 wire EDM (top right) and Ingersoll Eagle V550 five-axis (bottom center). Photo Credit: MC Machinery

EDM, Milling Systems for Mold and Die Application Enhancements

MC Machinery offers wire and sinker EDM machines, including a new Mitsubishi artificial intelligence (AI)-enabled sinker EDM as well as other EDM and milling machines like the Mitsubishi MV2400 wire EDM and the Ingersoll Eagle V550 five-axis milling center that are accurate, cost-effective and provide optimal speed and performance for manufacturers.

Photo Credit: Engel

Training, New Technologies Target Mold Change Optimization

Injection molding machine and automation supplier Engel offers an array of technologies to simplify and speed up mold changes, including magnetic clamping platens and quick couplings; intelligent assistance systems; and the famox mold changing system for automating the setup process. In addition, the company is now providing three different training courses that are tailored to customers’ different requirements on the basis of the conditions in the plant and the know-how of the production staff.

Photo Credit: Swiss Steel Group

Mold Materials Guide Eases Steel Selection

The Materials Guide from the Swiss Steel Group supports mold builders in their search for the right steel solution according to individual requirements. User get a quick overview of the wide range of applications offered by Swiss Steel’s various steel grades for important application industries. Features include a quick and easy overview of important applications, examples of steel grades and steel types and the supplying business unit.

Related Content

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

Software Technology to Meet Moldmaking Challenges

Featured in this technology roundup are software solutions that can provide and improve design and manufacturing operations or data management practices during the manufacture of a mold.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More