Online configurator streamlines the quoting process for standard and custom mold bases; what once took days now happens in real-time. Source | PCS Company

D&M Tool Corporation is a busy mold builder. According to General Manager Brad Cummings, his team is always on the lookout for supplier products and tools that can streamline the mold-building process. One such tool is the mold base configurator from PCS Company. Cummings mentioned that this valuable resource was almost overlooked initially.

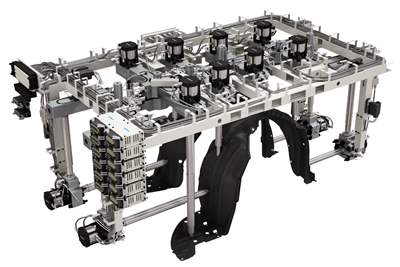

D&M Tool’s 18,000 sq. ft. Indiana facility features state-of-the-art machines and CAD/CAM systems, staffed by skilled toolmakers committed to timely, precise service.

Located in Springville, Indiana, D&M specializes in manufacturing small to mid-size injection molds. They produce molds ranging from single cavity to 16 cavities, as well as die-cast tooling and machining of components in their 18,000-square-foot facility. The company's expertise lies in molds for automotive lenses and they also cater to the electronics (lighting for airports, parking lots, retail stores and headlights for cars) and medical device industries. Sister company, PRD, Inc., also based in Springville, offers tight-tolerance injection molding services and operates most of the molds built at D&M. Press sizes at both companies range from 20 tons to 610 tons. D&M and PRD, Inc. are divisions of Specialty Manufacturers Inc.

Cummings recalls that it was about a year ago when they first heard about the mold base configurator from PCS Sales Representative Mike Hyde. “I was too busy to even consider it. It seemed easier to stick with our previous mold base supplier, as we were satisfied with their service and pricing,” says Hyde.

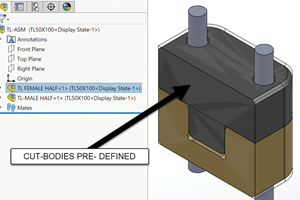

After persistent encouragement from Hyde, Cummings finally agreed to test out the configurator. “Tim Pruett, our mold designer, was the first to place an order. He had the previous supplier's mold base data saved on his computer, and we were worried that PCS's data might not be compatible, which would make it difficult to set up everything the way we needed,” he explains.

When the mold base arrived, Cummings asked his team to carefully inspect every aspect of the order and inform him if they noticed anything that was out of specification or missing. He was relieved to find that their concerns were unfounded. According to Cummings, everything was perfect and matched the 3D models exactly as Pruett had specified on the prints.

Streamlined Efficiency in Mold Base Ordering

The company has placed orders for several mold bases in the past few months and has also provided quotes for many more. Cummings is consistently impressed by the speed and ease of use of PCS's mold base configurator. The efficiency of the configurator has had a significant impact on D&M's project timelines, allowing them to order mold bases more quickly and receive them faster. “This accelerates our project timelines and enhances customer satisfaction,” says Cummings.

Mold designer Tim Pruett (above, left) and GM Brad Cummings (above, right) show off D&M Tool’s capabilities. Its advanced CNC technology enables the production of aluminum and steel molds, prototypes and components within three to five days, meeting precise SPI classifications and customer standards including its new Roeders five-axis, high-speed milling machines.

The development of this enhanced system by PCS wasn't by chance. “We

already had a configurator in place, but we knew we needed to do more. We studied the limitations carefully to understand how to expand the product line and enhance the customer experience. This led us to adopt new technology and create a new generation of standard mold base configurators,” says Joe Esposito, PCS engineering manager.

The system dynamically offers compatible components based on the customer's mold base configuration, ensuring all components within the assembly, including quantities and part numbers, are correct. This smart selection technology has eliminated previous issues with incorrect selections and typos that often led to product returns and delays.

“I simply log in and use the drop-down menus within the order form to choose the type of mold base I want, along with the machining features and components needed.One great advantage is that the configurator calculates the price as I go line by line, selecting or removing any aspect of the order, so I know in real-time exactly what everything costs. If I quote a job for a customer and later we get the P.O., I can go back into the configurator and order the mold base without having to re-enter anything. The entire process takes me about a minute, and boom, it's done. I get a confirmation email immediately with delivery details, and each order has arrived correct and on time, usually in just three to four days.” says Cummings

“The system dynamically offers compatible components based on the customer's mold base configuration, ensuring all components within the assembly, including quantities and part numbers, are correct.”

Cost-Effective Solutions and Enhanced Support

Cummings and Pruett expressed their appreciation for the level of customer service provided by PCS. For example, the first time D&M used the configurator, they could not find the locating ring to fit the company's standard. Pruett called PCS's Hyde, and he promptly resolved the issue. This kind of responsive support is no accident – PCS maintains a robust feedback system, with their sales and estimating teams regularly collecting customer input to drive improvements. The engineering team targets annual enhancement updates based on this feedback, along with planned product improvements.

“One of our primary goals was to clear all the bottlenecks we identified in the previous version.The improvements in speed, accuracy and ease of use have helped us retain and expand our customer base significantly,” says Esposito

D&M Tool Mold Designer, Tim Pruett, specifies a mold base on the online configurator.

The integrated interface generates CAD models, BOMs and quote documents dynamically, enabling thorough verification before placing orders. Customers can instantly get quotes and delivery times for multiple configurations, helping them make better decisions. This self-service approach means users can work on their projects regardless of the time of day or day of the week, without requiring human interaction.

Cummings mentioned that the pricing is more affordable than with previous suppliers, with every mold base ordered offering noticeable savings. Because PCS has removed the cost associated with quoting these mold bases, they have been able to pass along these savings to the customer. Additionally, the products are more readily available and often shipped and delivered more quickly.

Cummings and Pruett mention another added benefit of working with the 3D model in the mold base configurator. They explain that the chamfers on the corners are not displayed, which makes it much easier to create the drawings. They also note that when the mold base is delivered, the chamfers are there as designed.

The adoption of the configurator has opened up new opportunities for D&M. It enables them to take on more jobs by responding to quotes more quickly and accurately. Cummings says, “We’ve obtained more jobs by meeting our deadlines faster.” This efficiency has helped them reduce stock levels because they only order what is needed when they need it, improving their inventory management and cash flow.

D&M Tool is currently using PCS’s standard mold base configurator, which provides frame options ranging from 7.875 inches × 7.875 inches to 23.75 inches × 35.5 inches. The A and B plate thicknesses offered range from 0.875 inches to 5.875 inches, all available in either #3 or #7 steel. PCS also offers its F.I.T.S. (Fast Interchangeable Tooling System) Insert configurator, compatible with its MUD and RTI frames, which D&M intends to use for future jobs as needed.

“The mold base configurator has greatly improved our ordering and quoting process. It is now our primary source for mold bases, along with PCS's pins, parting line locks, lifters and other products that we use for every mold we build,” says Cummings.

Related Content

VIDEO: Taking a People Before Product Approach to Growing a Business

Angela Elsey, President of PCS Company, shares her journey into moldmaking, perspective on the industry and plans for the business.

Read MoreWhat is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

Read MoreProducts and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

Read MoreRead Next

VIDEO: Mold Component Advancements & Hot Runner Insights

Advancements in mold components, hot runner temperature control and custom manifold configuration that address cycle time, quality and sustainability issues.

Read MoreEjector Pin Selection Guide

A review of materials, treatments and coatings to help determine the proper pins for optimized plastic part ejection.

Read MoreHow to Build a Better-Performing Hot Runner Mold

Early stage communication across the supply chain about design considerations optimizes hot runner mold performance.

Read More