A major hurdle mold builders face when it comes to configuring wire EDMs for completely unmanned continuous operations is slug removal. Even as machine tool manufacturers transform metal-cutting applications with state-of-the-art automation solutions, operators of wire EDMs must deal with slugs the old-fashioned way. Despite decades of effort, stopping the machine and manually removing slugs has remained the overriding norm.

Slugs will fall onto the lower head of a wire EDM and can cause a fatal crash or trigger work-stopping crash protection routines when left to their own devices. CAM programs can prevent this by including tabs (only 0.100-inch thick) that keep the slug connected to the workpiece during cutting. Once the software completes that step, the operator then cuts these tabs off and removes the slug by hand.

On average, this task adds an extra five to six minutes per tab to every EDM cycle and prevents unmanned operation. At best, shops will program EDMs to rough cut parts unmanned and overnight. The next day operators remove the slugs and run the finishing passes.

Small and Light Automated Slug Removal

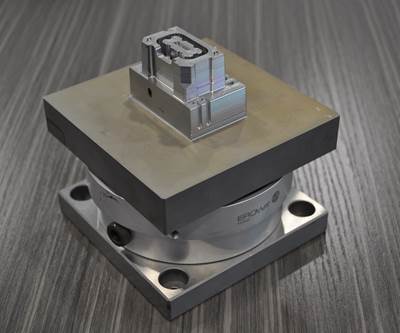

However, shops that use a new automatic slug management system that incorporates Bernoulli’s principle (the same property of fluid dynamics that allows planes to fly) can reduce all this manual labor. The system helps to ensure that shops can run their EDMs in a true unmanned, lights out operation, shorten cycle times and complete both roughing and finishing with zero operator intervention. Also, it is especially well-suited for small-cavity EDM operations and die-stamping applications.

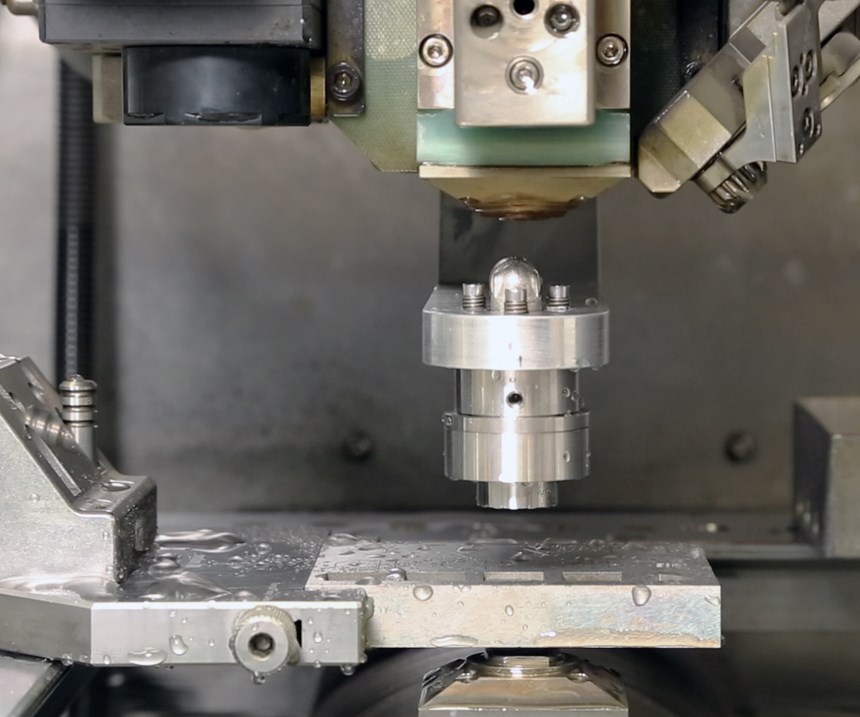

The automated process begins with a complete roughing pass, leaving no welds or tabs behind. Instead, the machine’s design enables the lower head to catch the slug before it falls into the tank. A device retrofitted to the upper head then lowers and blows high-pressure air over the slug, which creates suction that pulls the slug from the part. The machine’s upper head then moves along the U and V axes to deposit the slug in a receptacle before returning to perform further operations on the part.

While automatic slug management is a somewhat slower process than its manual counterpart, the fact remains that it requires no human intervention. Manufacturers can load raw material into the machine in the evening and take fully finished parts out in the morning. Shops can run continuous machining operations and reduce total processing times by an average of 20%.

Because it uses suction, the system does require enough surface away from wire EDM start holes that can impede its operation. Naturally, slug weight and size are also limiting factors (10 by 10 mm and larger, and less than 0.6 pounds). In those situations, shops can remove small slugs with a pocketing strategy that uses the EDM wire like a milling cutter to machine off the slug.

Automatic slug management and automatic slug welding solve these slug removal problems and fully automate many EDM processes.

Large and Heavy Automated Slug Welding

However, applications involving heavy (0.6 pounds) slugs and large cavities will continue to use automatic slug welding. During normal operation, brass EDM wire slowly melts away and leaves behind minuscule amounts of brass buildup, but excess energy, slow wire movement or insufficient coolant can significantly increase that buildup. This buildup, in turn, reattaches the slug to the workpiece with brass.

Despite dramatically shortening cycle times, automatic slug welding does fall short of true uninterrupted automation because the process still requires an operator to remove the slug manually. The operator must knock the slug out using a brass hammer and manually remove the slug from the cavity to continue finishing the cavity.

However, a slug welding method in a system that uses clever G-code commands to precisely manipulate the brass accumulation prevents top-to-bottom welds and generates 0.100-inch-thick welds at the top of the part that joins only the surface of the workpiece and slug. The result is a slug that operators can easily knock out of the workpiece with a brass hammer, leaving behind brass that won’t interfere with a skinning pass or other finishing operation.

Automatic slug welding does eliminate the time needed to cut slug tabs and shortens the processing time to about two minutes. However, if the wire breaks mid-cut, a machine without the ability to rethread inside the gap will have to restart the entire program from the beginning due to new welds in the way. Thin sheets of material or small slugs are other challenges that require careful selection of weld points.

Automatic slug welding surpasses previous slug management systems such as pin-based and ejection-based systems. The pin of the pin-based system inserts itself through the wire start hole and expands outward to grip the slug and pull it through the gap following the cutting program. Unfortunately, given the size of the device, it was often unable to fit through most narrow wire start holes and could only securely grip relatively light slugs, preventing use on large or heavy slugs.

The ejection-based system ejected the slug into the machine’s tank. It retains tabs in the form of tiny triangular connections that hold a slug until a piston knocks it through the cavity and into a waiting receptacle. This allowed for full automation in theory, but in practice, operators had to fine-tune the device so the slug would fall cleanly through the cavity rather than jam the machine.

Automatic slug management and automatic slug welding solve these slug removal problems and fully automate many EDM processes. Despite the focus on the cutting area, machine tool manufacturers know that the next step in automation involves consumable usage. For example, automatic threading and rethreading are possible with current technology, but the future will deliver machines that can automatically alert operators when a machine has an insufficient wire supply on its spool to complete a part. This alert will help avoid production interruptions and ensure truly unmanned automated EDM part processing.

About the Author

Eric Ostini is a product manager at GF Machining Solutions.

Related Content

How to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreHow to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreRead Next

Linear Motor Drive on Sinker EDM Machine Speeds Productivity

Linear motor technology in a sinker EDM machine enables Action Mold and Engineering to burn faster, more efficiently and more economically with minimal maintenance.

Read MoreThe Impact of 3D Printing on Wire EDM

3D printing impacts wire EDM workholding, cutting conditions and machine tool specifications.

Read MoreAdvanced EDM Features Increase Efficiency and Change Perceptions

Unique features that drive optimum speed and accuracy in the EDM process helped change Viking Tool’s views on, and use of, EDM technologies.

Read More