SPE Mold Technologies Division Honors Charles Klingler

The Mold Technologies Division of the Society of Plastics Engineers (SPE) honored Charles Klingler of Janler Corp. at Amerimold 2018.

“OMG, I am stunned and humbled. I am still shaking and so glad that I was sitting down when I got the news! What did I do that qualifies me for this??”

Anyone who knows Charles (Chuck) Klingler, vice president of Janler Corp. in Chicago, Illinois, can envision him saying those words when he learned he would be honored as Mold Maker of the Year by the Society of Plastics Engineers (SPE) Mold Technologies Division.

Each year, the SPE Division recognizes individuals who have supported and advanced the moldmaking industry by making contributions above and beyond the norm. Both a Mold Maker of the Year award and a Mold Designer of the Year award are presented along with a $500 honorarium that is donated to the trade-related education program of the honorees’ choosing. Lake Park High School in Roselle, Illinois, will be the beneficiary of Chuck’s check from SPE. (Stay tuned for news about this year’s recipient of the SPE Mold Designer of the Year award.)

Chuck is well respected in his field of high-precision mold manufacturing and is, in essence, the face of Janler because he represents the company’s products and services to its many customers as VP of sales. But he gives so much more than a smiling face and customer support; he is involved and working toward the betterment of the industry.

Currently, Chuck is president of the American Mold Builders Association’s (AMBA) Chicago Chapter. Janler is a founding member of the AMBA. For many years he has supported the Chicago Chapter including actively participating on its education committee, which has made notable strides in its efforts to increase the exposure of moldmaking to young people in junior high and high schools in Northern Illinois. Additionally, Chuck has been instrumental in organizing and working with major manufacturing companies like GF Machining Solutions to put on career fairs. He spends hours volunteering his time at other career fairs, too, talking with students, their parents and teachers about rewarding career opportunities in moldmaking.

With regard to workforce development, Chuck is on a mission with the rest of the members of the AMBA Chicago Chapter, and he expressed it in his acceptance speech during Amerimold: “Our industry needs to continue to work to educate young people about the great careers available in moldmaking. Without them, our industry will go away,” he said. “This profession has been very good to me---to all of us. It is truly an honor to be given this award and I thank everyone who considered me to be worthy of it.”

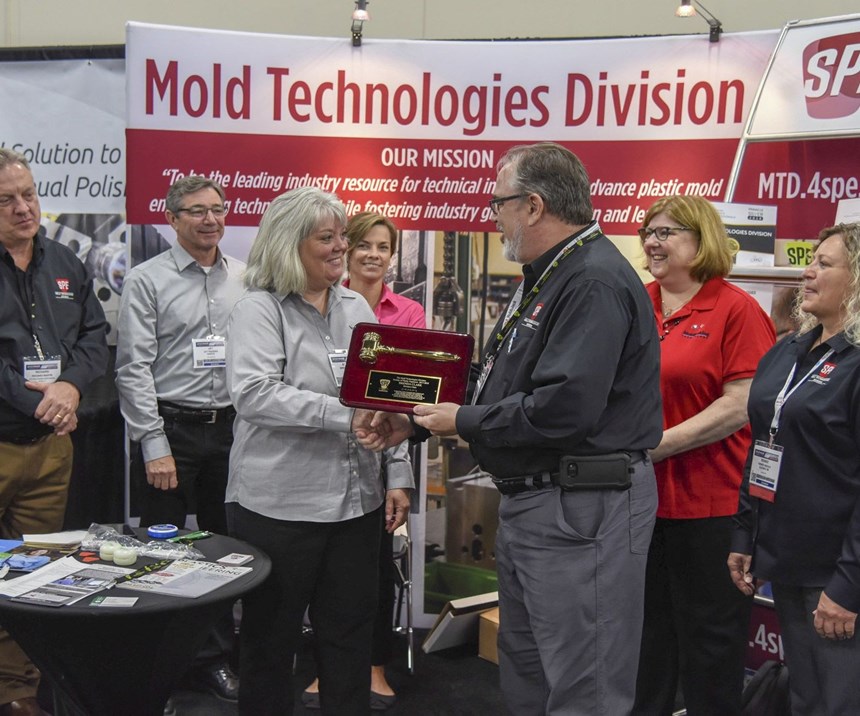

He also mentioned that almost exactly 30 years ago, his father, the late Josef Klingler, was also honored as Mold Maker of the Year by the SPE, and this made it all the more special for Chuck and his family, his colleagues and the team at Janler. Several people gathered for the presentation at the SPE booth during Amerimold, many of them colleagues in the industry, to help celebrate.

The SPE Mold Maker of the Year award was first established in 1983. In addition to his father, Chuck joins fellow honorees and industry icons like Glenn Beall, Fred Steil, Manfred Hoffmann and Joe Prischak, the man whose idea it was to create MoldMaking Technology Magazine. Congratulations, Chuck!

Passing the Gavel

In addition to bestowing awards during Amerimold, the SPE Mold Technologies Division also announced its incoming division chair, Renee Nehls of Sussix IM. Nehls happens to be the division’s 2017 Mold Designer of the Year. She will officially take the reins of the division on July 1, when current Chair Brenda Clark of Hasco America steps down from the post.

“Brenda has left me big shoes to fill,” Renee says. “She is a talented mold designer, a strong woman and she led our division with dedication and a focus on achieving important goals like launching our new website, participating at more industry events, recruiting more members and so on. She did a great job and I hope that I can help further the goals she set forth.”

Related Content

More Than Moldmaking at PTXPO 2023

The Moldmaking Pavilion returns to the Plastics Technology Expo (PTXPO) March 28-30, 2023, at the Donald E. Stephens Convention Center in Rosemont, Illinois, but there’s more to discover than moldmaking.

Read MoreMoldmaking, the Relentless Pursuit of Innovation … Oh Yeah!

Innovation was at the root of the presentation lineup for the 2023 MoldMaking Conference, which included a heavy focus on automation, collaboration and communication, as well as mold design, talent development, reshoring and sustainability.

Read MoreWhere Mold Manufacturing and Plastics Processing Connect

The Moldmaking Pavilion is one of seven pavilions returning to the show that houses exhibitors offering technology and service solutions for your specific moldmaking needs.

Read MoreMoldMaking Technology's Leadtime Leader Awards Competition Returns!

After a brief hiatus, MoldMaking Technology’s Leadtime Leader Awards Competition is back!

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More