2011 Leadtime Leader Awards: Large Shop Winner

United Tool & Mold, Inc.: Charging Forward with Unique Mold Repair Niche.

UTM has 70 employees spread throughout its three locations, primarily serving the automotive, lawn and garden, appliances, large truck and power tools markets. In addition to mold repair, UTM also builds plastic injection, blow and compression molds as well as performing engineering changes, engineering services, service-on-site, laser welding and in-house texturing. The company also has formed an alliance with Melco—a Michigan-based texturing and graining supplier. Melco works with UTM in-house to provide re-graining engineering changes without the tool ever having to leave the UTM shop floor, which ensures shortened delivery times and reduced costs for the customer.

The acquisition of Jungwoo USA is another step toward the company’s goal of being a full-service supplier. “Jungwoo USA is a leader in supplying new tools from Korea and China, with a reputation in the market for providing high quality tooling built in 30 to 60 days as well normal everyday deliveries at prices competitive in the market place with support provided by UTM,” UTM President Scott Phipps explains. “We have brought them back under our umbrella as a new tool supplier for a truly global outlook. Jungwoo—which will be known as UTM in the future—will manage new tool builds from all regions of the globe in order to bring the customer the best possible solution for their business.”

UTM “will do whatever, whenever, wherever to keep the plastics industry running, Phipps adds. “That is how our business is structured; and that is how we remain in a state of growth even during the recent economic struggles. We don’t tell customers no, we find a way. In a book written by Scott Alexander, Rhinoceros Success, it describes how a rhino always charges and never backs down. Whether we make a mistake or not, we are going to charge forward. Mistakes we can fix; we simply cannot get back time we have lost procrastinating. We are more of a solutions-driven company. We call it having a Rhino Attitude.”

The Rhino Attitude

According to Phipps, the company embraces a “nothing is too much for us to handle” motto—incorporating many of the philosophies of the aforementioned Rhinoceros Success. “To us, ‘Rhinoism’ is a way of life,” Phipps notes. “It marks our discipline, our audacity, and our persistence. This discipline allows us to always make sure the customers’ needs are met.

“We are willing to go above and beyond to make sure that our customers are taken care of,” Phipps continues. “We believe that our responsiveness to customer needs is second to none. With our fleet of trucks and willingness to stay until the work is done, we are able to offer unmatched response time to customer emergencies. Our trucks allow us to be on the road to a customer facility within minutes of receiving a call for service. Our new service-on-site van is fully stocked with the tools to take care of repairs at a customers’ facility.”

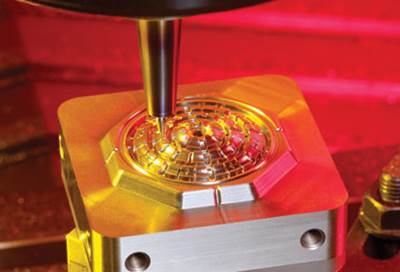

This philosophy also keeps the company’s leadtimes lean. “We are able to move our large machining jobs through the shop quicker now with the five-axis machining capability,” UTM Quality Manager Jeromy Arnett notes. “We simply cannot get any faster at turning around jobs than we are right now. Whether it is three hours, three days or three weeks—our leadtimes are predicated by what the customer needs.”

Charging into the Future

UTM hopes to expand its operations. “Ultimately, we are trying to align ourselves with global resources so that we can offer our customers solutions—independent of location,” Phipps notes. “We are able to offer unmatched service due to the fact that we are willing to look for partnerships with not only local and regional companies, but also global companies. We work with shops like Roller+Schneider and Laepple to provide our customers with support on new tooling projects and engineering changes. Roller+Schneider specializes in gas tank blow molds. Working with Roller+Schneider employees has allowed us to gain more knowledge in working with blow molds.

“Likewise, we worked in conjunction with Laepple on extremely large tooling for the automotive sector,” Phipps continues. “The molds were shipped in to the U.S. and we provided start-up services—including inspection of tools upon arrival, cleaning and prepping for sampling and tuning of all molds to help the customer meet the OEM deadlines.”

The company’s long-term goal is to be a “mold mall” to its customers. “Our purchase of JungwooUSA offers our customers a source for new tool builds,” Phipps emphasizes. “From design through to production of plastic parts, we want to be able to provide any and all services under the UTM umbrella.”

Related Content

Making Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreWhat is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

Read MoreThe Critical Role of Management Representatives in ISO 9001

In ISO 9001 quality management systems, the Management Representative (MR) plays a crucial role. While the 2015 version of ISO 9001 no longer mandates this position, having a trusted management member serve as an MR remains vital for streamlining operations and maintaining quality standards.

Read MoreRead Next

2011 Leadtime Leader Awards: Small Shop Honorable Mention

JM Mold South, Inc.: Constant Reinvention Results in Growth, Success.

Read More2011 Leadtime Leader Awards: Small Shop Winner

Mold-Tech, Inc.: Technology-Driven, Detail-Oriented Precision Injection Mold Provider.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More