Advances in Hot Runner Systems Drive Innovations in Part Engineering and Styling

Design and performance capabilities of components fabricated in state-of-the-art molds enhance the appeal of new vehicles.

Developing injection molds that combine high-tech process capabilities with productivity and economy is at the core of automotive moldmaking. As plastics continue to make gains in this market for aesthetic and practical reasons, toolmakers are incorporating growing levels of complexity and performance in their molds.

A major route to enhanced mold engineering is the use of hot runner systems that meet expanded process needs while contributing to quick mold-build capabilities and life-cycle cost reductions. Hot runner suppliers are fine-tuning products, and in some cases adding new lines, components and capabilities, to meet the engineering needs of leading-edge automotive parts.

At the same time suppliers are responding to a continuing emphasis on fast fabrication and timely delivery of new molds with modular systems that are designed to reduce mold-building times, minimize maintenance and permit fast changeover when components need to be replaced.

Recent Automotive Developments Affecting Mold Design

The result is a range of custom and standard hot runner systems that suit diverse moldmaking needs. Recent developments in automotive parts highlight some of the applications that are affecting mold design:

- The emergence of large parts like exterior vertical body panels and glazing, both with their own challenging process requirements, and continuing developments in bumper fascia, instrument panels and lenses, are expanding the need for hot runner systems that can be placed precisely within molds and accurately controlled to assure repeatable production.

- Multimaterial molding, a growth area for interior and exterior parts as well as underhood components like valve covers with integrated gaskets, raises issues that range from thermal management of dissimilar materials to preventing flash, knit lines and weld lines, and other cosmetic problems. Hot runner design is an important factor in eliminating flow-related problems, controlling shear and assuring adequate loading and packing of materials.

- The use of long-glass reinforcements to raise the strength of commodity plastics near that of costlier and harder-to-process engineering thermoplastics, are promoting nozzle designs that minimize fiber damage and maintain on-spec loading ratios during injection.

Technology Advancements

One example of products designed to meet these needs is the Ultra line from Husky Injection Molding Systems (Bolton, ON). Husky can supply the hot runners as standard components in either hot halves or manifolds, and customize them for various applications. Custom techniques for large or multimaterial moldings that require sequential flow include the ability to place a valve gate on the center of a part. “This eliminates weld lines and knit lines by allowing a moldmaker to provide a tool that fills seamlessly from the center out,” says John Daniels, Marketing Manager for Automotive Hot Runners.

A large part filled from the center typically utilizes a sprue bushing with two valve gates straddling it. This creates a weld line that’s usually hidden with an emblem or other device. Techniques Husky employs to “gate on center” include installing a self-contained, single-cavity valve gate beneath a sprue, or using a spacer plate to transfer melt and provide enough clearance for a valve gate under a sprue.

The line has six sizes, each designated by a number that corresponds to its outer diameter in millimeters: 250, 500, 750, 1000, 1250 and 1750. Large-part molding generally requires at least a 750mm.-dia. nozzle.

Daniels says the 1750mm. nozzle is finding use in one emerging application: exterior body panels molded of polypropylene. (Cars with polypropylene body panels include the Honda Element.) The Ultra 1750 is ideal for this because its large nozzle channels improve the flow of long-glass fibers that reinforce such parts.

The Ultra line, like some competitive hot runners, utilizes internal components that assure process quality in different ways. These include “UltraGuide,” a feature for valve gates that prealigns the valve stem prior to contact with the gate area, and a thermally conductive tip that facilitates startup and widens process windows.

Speed and economy in mold building are driving developments at Gunther Hot Runner Systems (West Chicago, IL). The company specializes in hot runners for high-temperature underhood parts and small engineered automotive components. One specialty is extremely small pitch centers—down to 7mm. The benefit to this in multicavity tools, says Joe Podge, General Manager, is it allows moldmakers to maximize the number of nozzles and cavities in a given mold base size, which generally permits processors to run parts on smaller presses, thereby reducing manufacturing costs.

Gunther recently launched a hot runner design system moldmakers can access called CADHOC. Available through its Web site (www.gunther-usa.com), CADHOC is a password-controlled, menu-driven program that lets moldmakers select a nozzle, pitch center, manifold and related mold components based on part size and material.

Data are processed by Gunther’s CAD library of nozzles and components. According to Podge, it takes about five minutes to input data, and another five minutes to get either a complete 3-D model or a 2-D drawing, which can be downloaded, manipulated (as in the case of the 3-D model) and used in mold development.

“Our customers are increasingly looking for speed,” says Podge. “They want to get their mold designs underway quickly. More conventional methods can take a week or two to get the hot runner information CADHOC supplies in minutes. If you can do this by yourself in five to 10 minutes, it really changes the dynamics of moldmaking.”

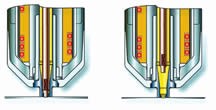

Do-it-yourself hot runner design isn’t Gunther’s only innovation of late. The company has also developed an internal component for valve gate systems on large molds like those for automotive lenses. Called Gate Guardian, it’s a powdered-metal insert about 4mm. in diameter, through which a cylindrical valve pin is guided during injection. The insert comes to the part surface and becomes part of the gate during injection. The benefit of the device, Podge says, is preventing nozzle-tip wear in molds for lenses and other large parts, which often use tapered valve pins, a geometry that causes gate wear in the parent steel that can lead to flash and may damage the core. If the insert needs changing, it can be replaced as an extension of the nozzle tip, thus minimizing maintenance and mold downtime.

One notable use of an internal component to boost performance and control is found in the hot runner system developed by Synventive Molding Solutions (Peabody, MA) for polycarbonate (PC) glazing. Automotive glazing is an emerging market with huge potential for its benefits over glass in light weight, design flexibility, styling and crashworthiness. In the U.S. it is a long way from being approved for windshields—an application it may never get—but it’s beginning to appear on side and rear windows and in vehicle roofs.

Synventive supplied a model EC KNG 280 hot runner nozzle to injection machine maker Battenfeld, for use in molding glazing in a single-cavity mold with the IMP-more process co-developed by Summerer Technologies of Germany, and first exhibited at NPE 2003. The PC parts are 1050 by 1050mm. (41 inches) in size, 4mm. thick and weigh 5000 grams (10 pounds). The hot runner and manifold utilize a special grade of steel (undisclosed) and a tip with an insert that’s engineered to mini-mize shear and thus help reduce optical defects in the part, which must be molded in a low-stress process.

John Roggenburk, Synventive’s Marketing Manager, declines to reveal details about the insert, but notes it too is a special material that, with the rest of the hot runner system, maintains a uniform temperature during molding. “This application demands a hot runner delivery system that controls the temperature of the melt within 3°F,” he says.

For more mainstream applications, Synventive recently introduced two hot runner nozzles: 04 C01 and 04 C02. Available in lengths to 186mm. and flow-bore diameters of 2.5-6mm., the nozzles have a number of features that are designed to simplify moldmaking. The C01 version, which replaces Synventive’s CA series nozzles, has interchangeable heaters that can be removed from the front or rear, depending on the mold. The C02 line has a nozzle head that separates axial and radial positioning; a positioning joint that lies flat on the surface of the mold plate; and cables for heaters and a thermocouple installed in the direction of the nozzle tip, which means they can be replaced from the front of the runner.

The nozzles operate with a new hydraulic valve gate cylinder, the HYC 2508, that bolts to the manifold, is compact and provides tight gate pitch. A pneumatic version is optional for cleanroom molding.

Mold-Masters Ltd. (Georgetown, ON) combines a small footprint with modular construction and ease of installation in its Fusion-Series hot runners and manifolds. Doug Hugo, Automotive Sales Support and Technical Service Manager, says the product, delivered pre-assembled, pre-wired and pre-piped, takes about an hour to install.

Described as ideal for large parts, single-point hookups for water and hydraulic or pneumatic actuator connections minimize pocket cut-out sizes in molds when installing the manifold. Hugo says this reduces the amount of machining required and reinforcement of the area around the cut-out. The single-point connections also simplify maintenance.

One feature of the Fusion nozzles is a valve pin bushing that forms a tight seal with cooled polymer around the pin after injection. Hugo says the seal prevents material from beading up or leaking around the pin, and acts as a lubricant. The cold seal is achieved by cooling the valve pin through the actuators. Because of the seal, Mold-Masters is able to open up the tolerance between the pin and bushing, which helps reduce manufacturing costs. The nozzles come in diameters of 11-24mm. and gate sizes of 4-8mm. Valve gate pins are 6-10mm. long.

Ewikon Hot Runner Systems of America (East Dundee, IL), meanwhile, has updated its electric-drive valve gate unit for sequential molding. The hot runner system, which utilizes a stepping-motor drive for accuracy and repeatability, was unveiled at the NPE last June. (See “Industry Focus: Electronics,” October 2006, page 38.)

Ewikon recently added a sequential logic control to the software that regulates the electric drive. With sequential molding, processors who prefer an electric drive for its cleanliness and precision can eliminate knit lines in large parts, especially those that will be plated, says Dave Boxall, General Manager.

Summary

The enhanced performance capabilities of these and other hot runner systems give moldmakers the means to produce high-quality tools for a range of automotive parts in a timely and cost-effective way. Advances in hot runners maintain the moldmaker’s role as an enabler of the styling and performance features that define the look and desirability of new vehicles.

Patrick A. Toensmeier has been writing about the plastics industry for 20 years. He can be reached at toensmeier@sbcglobal.net.

Related Content

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreRead Next

It’s Gut-Check Time for Tool Builders

It’s time to adapt or die as business evolution dictates development of new business and manufacturing approaches.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More