2013 Leadtime Leader Awards: Honorable Mention Micro Mold Company, Inc.: Partnering to Push the Limits

This mold manufacturer wins the 2013 Leadtime Leader Honorable Mention title because it exceeds expectations with a team mentality—stemming from its youthful leadership working closely with skilled tradesmen—that sees customers, its sister molding company and industry associations as true partners.

The New Face of Mold Manufacturing

Micro Mold Company, Inc. (Erie, PA) may have only 20 employees, but its team mentality—instilled by its youthful, well-educated leadership and experienced, skilled tradesmen—yields partnerships with people, processes and promotion that has allowed the company to evolve into a premier custom injection moldmaker specializing in the design, development, and manufacturing of highly engineered, tight-tolerance, thermoplastic injection molds as well as the delivery of final products to its customer base.

Micro Mold concentrates on medical disposable, dental, consumer products and minimally invasive surgical products for the following market segments Eye/vision care, diabetes care, medication delivery systems, fluid control, electronic connector, aerospace, defense, automotive, and telecommunications. Micro Mold specializes in building single-cavity, multi-cavity, hot runner, cold runner and three-plate molds, with a primary focus on tight-tolerance, highly complex, SPI 101 production level injection molds. Leadtimes range from eight to 14 weeks.

Productive People

Key to Micro Mold’s success is its partnership with Plastikos, which allows Micro Mold to focus on molds and processing, notes Micro Mold President and General Manager Ryan Katen. “It’s difficult when a moldmaker is not partnered with a molder or doesn’t have a common ownership in a molder,” he states. “Our alliance with Plastikos is a definite competitive advantage. When your sister company is a molder you can look at the big picture on a project—the total potential revenue stream rather than just the tool build. We can count on Plastikos because we know exactly what we are getting. We can design and build a tool and know that it is going to run extremely well in production for many, many years—even decades—throughout the entire life of the product line.”

Of course, Micro Mold’s own employees are another secret to the company’s success, as they play a vital role in putting the right processes and strategies in place throughout the mold manufacturing process. The company takes pride in the fact that the company has hired degreed plastic engineers in its tooling and molding department. “Our Engineering Manager was one of the first graduates from Penn State’s Plastic Engineering program and began his career with Micro Mold in 1991,” Katen notes. “This is a major benefit to our customers since he (and others) can effectively communicate and find solutions to potential product risks (undercuts, non-uniform wall thickness, hesitation regions within the design, gating location, for example). This added level of expertise and support is truly what separates Micro Mold from our competition, which may not have this in-depth, plastics engineering understanding and experience with respect to plastic phenomena within the mold.”

The company also believes in a “grow your own” philosophy, and as such, has partnered with Penn State–Erie, The Behrend College. “This branch of Penn State is one of only a handful of colleges in the nation that offer a Bachelor’s degree in Plastic Engineering Technology,” Katen says. “The professors in this engineering program have decades of real-world experience in the moldmaking, processing, design, and manufacturing fields. Our close relationship with Penn State allows us to recruit knowledgeable and skilled employees who arrive at Micro Mold and Plastikos ready to join our Team. This thorough education program teaches students proper mold design, scientific injection molding principles, and eliminates the ‘black art’ of plastics.”

Micro Mold’s four-year apprenticeship program involves 576 hours of night school classwork in conjunction with 8,000 hours of on-the-job training, Katen says, adding that Micro Mold trains them in all facets of the mold fabrication process.

Last year, Micro Mold introduced a new company and individual incentive bonus program that builds upon—and expands—a similar program launched by Plastikos. “The purpose of this program is to reward employees for individual and team contributions to Micro Mold’s success, tie individual earnings (bonus) directly to the efficiency and profitability of Micro Mold & Plastikos, and provide an additional incentive to individually contribute to both companies’ efficiency, continuous improvement, etc.—as well as to encourage teamwork.”

All employees, from an entry-level up to our departmental managers, were eligible under the new bonus program, Katen continues. The bonus program was funded based on the companies’ financial performance (sales, gross profit margin, and net profit margin) during the fiscal year. “Our Management Team happily reported that the FY12 bonus pool of $325,000 was established and funded,” he adds. “The individual bonus allocations were distributed last November, when many employees received individual bonuses of $2,500 or more.”

Katen believes that programs like this is one of the company’s greatest strengths. “Of the 20 men and women we employ, we are proud of the fact that more than half of them have been with Micro Mold for longer than 10 years,” he comments. “Moreover, we have six members of our team who have been with us longer than 20 years and one individual that has more than thirty years of experience at Micro Mold. Our culture is a direct reflection of each individual member of our team, their strengths and abilities, passion for excellence and pride in their work, commitment to our customers, and dedication to our company.”

Committed Customers

Micro Mold also considers its customers partners—developing innovative methods and technologies to help customers get their products to market in the quickest possible delivery times. “Our team fully commits to the delivery date once a customer issues a purchase order,” Katen notes. “In some cases, our team’s commitment has resulted in significant overtime, up to and including operating a two-shift production schedule to hit our quoted delivery date.”

Pushing Processes

Before Micro Mold hones in on mold design and build, the company realized there was value in adding equipment to be more of a full service provider. To that end, the company purchased two all-electric injection molding machines (housed in the R&D Department) in an effort to minimize the mold validation phase of a project. “Now, when the Micro Mold team completes the design and fabrication of a new mold and it is ready for sampling, we have the ability to sample the tool on-site and then quickly make any necessary modifications or refinements to the mold,” Katen says. “Our in-house mold sampling capabilities have reduced the total time required to launch a new product/project for our customers.”

The company also provides short-term pre-production runs for its customers at Micro Mold, which Katen points out has been especially beneficial for its medical device OEMs, which frequently require their tooling supplier to complete extensive validation runs during the Operational Qualification (OQ) and Production Qualification (PQ) phases of their projects.

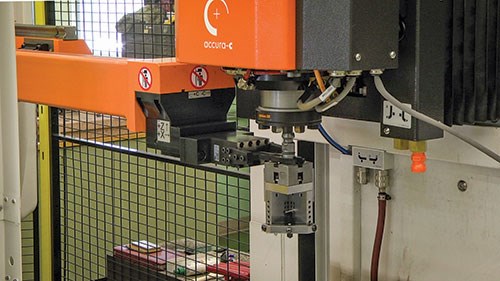

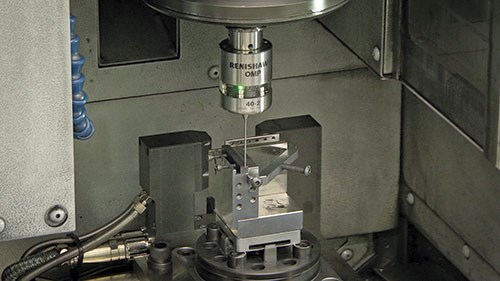

Micro Mold also recently completed the implementation of an automated CNC EDM workstation and CNC DMG/Mori-Seiki machining center that are both equipped to a System 3R WorkMaster robot. “The purpose of this manufacturing work cell is to streamline and automate multiple steps within the mold fabrication process, which results in significant efficiency and throughput gains,” Katen affirms. The company can machine an entire set of electrodes and move the electrode from the machining center over to the CNC/EDM machine in order to complete multiple steps within the manufacturing process, frequently overnight in a lights-out approach. “Our EDM room has historically been a bottleneck in our production processes due to the fact that multiple manual/semi-manual steps were required to manufacture a finished piece of steel,” he elaborates. “Specifically, the electrode must first be machined by one of our skilled toolmakers with the cavity or core feature, and then the EDM machine would utilize the electrode to burn that feature onto the steel insert.”

As mold cavitation increases, the bottleneck in this department became more and more pronounced, Katen continues, which in turn increased the risk of the on-time delivery for the entire mold fabrication. “Our team recognized this risk and launched a multi-phased continuous improvement project to improve the efficiency within our EDM department,” he says.

The first phase of this internal continuous improvement project consisted of enhancing the EDM department with a high-speed Mori-Seiki machining center. The team then purchased a System 3R robot to interface with the Mori-Seiki machining center. “The addition of the robot allowed for automatic pallet changing of the workpiece for multiple-piece production efficiency,” Katen notes.

To complete the capital investment phase of this project, Micro Mold purchased a GF AgieCharmilles CNC EDM and integrated it into the automated work cell, which dramatically increased efficiency since the robot now automatically moves an electrode from the CNC machining center and into a holding cell until it is needed to EDM a feature in steel, Katen adds.

“The System 3R robot is thus able to automatically change out the work piece in both the DMG/Mori-Seiki machining center and the GF AgieCharmilles CNC EDM. It is also able to automatically change the tool (electrode) out of the GF AgieCharmilles CNC EDM. Furthermore, one of our toolmakers can program the next job in the production schedule while the automated work cell completes the current job in parallel.”

This state-of-the-art automated manufacturing center affords the Micro Mold Team the ability to run around the clock in a lights-out environment, which maximizes the uptime on this critical equipment and subsequently increases the throughput within the EDM department, Katen states.

Implementation of Micro Mold’s first automated EDM manufacturing cell was completed in the Spring of 2011. Last November, the company decided to purchase a second, automated EDM work cell that will consist of an identical high-speed CNC DMG/Mori-Seiki machining center, a System 3R robot, and an GF AgieCharmilles CNC EDM. The second manufacturing cell is slated to be completed by late 2013, and it should yield the same dramatic increase in efficiency and throughput that were realized from the first automated work cell, Katen says.

Innovations’ Impact

The result of all this technology innovation and investment with its customers can be seen in this example. Two years ago the company was awarded a design, build and run package that consisted of six new molds for a medical device OEM. The mold cavitation ranged from four- to 32-cavitites, and each mold incorporated a hot-to-cold runner system. The leadtime on each individual tool ranged from 10 to 14 weeks based on the complexity and cavitation of each mold. “Therefore, we had to closely work with our customer to prioritize the mold delivery schedule based on the OEM’s project testing and qualification requirements,” Katen comments. “In an effort to minimize the total leadtime for the six-tool project, we released two molds at a time, which were separated by four weeks. Our proactive project planning enabled our team to strategically schedule the workload in order to minimize potential bottlenecks throughout the design and fabrication phases for each mold.”

Katen adds that each of the six molds were successfully delivered on-time, and Micro Mold was able to provide our customer with initial sample shots that fulfilled their testing requirements within one week of the mold delivery date. “Upon completion of this milestone, the Micro Mold team officially transitioned the project to the tooling engineers at Plastikos, Inc. The Plastikos Team then successfully led the qualification and validation phase of the project, which resulted in production approval from our customer. As a result of our collective efforts, Micro Mold was subsequently awarded two additional design-fabrication projects from this customer last year, and we are now slated to build an entire set of identical (backup) production tools for the project.”

In-house mold sampling services and engineering services are offered to all of Micro Mold’s customers. Katen notes the company used to send a completed mold to Plastikos for initial sample or directly the customer to sample. “However, this approach had the potential to result in wasted time and effort,” he says. Not only could there be multiple trips between moldmaker and the sampling site, but the customer usually requests or requires refinement before a mold is production ready—like optimizing the gate diameter, adjusting the ejector pin height, reducing drag along a straight wall or core feature or adjusting preplanned steel safe conditions.

Marketing Moxie

Clearly Micro Mold found the right formula for success with its partnerships that resulted in innovation—and success—with bringing products to market. Katen realized that he had to bring the company to the next level with its marketing efforts. So, it was time to again form a partnership—this time with a PR/marketing firm. Micro Mold hired Trefoil Group, Inc. (Milwaukee, WI) to help the company develop press releases, social media content (Facebook and LinkedIn pages), marketing tools like brochures, and industry articles that have been published by a number of trade magazines. Katen notes the company has budgeted more than $50,000 in marketing efforts with Trefoil Group this year. And, Micro Mold has budgeted an additional $30,000 for the design and development of a new tradeshow booth. amerimold, NPE, MD&M East/West, and Design-2-Part are amongst the shows where the company will exhibit.

“The articles, particularly within the medical device industry, have helped us realize a dramatic increase in our market and industry exposure,” Katen adds. “We have been awarded more than 25 new design and build projects from multiple customers within the medical device industry over the past two years alone. Moreover, Micro Mold quoted more than $3,000,000 worth of tooling work in 2012 for numerous medical device OEMs—many which are still open at currently being evaluated.”

Prosperous Position

Katen is extremely confident that Micro Mold is on the right track. “We have always pursued an organic growth strategy throughout the company’s history,” he says. “This growth strategy —coupled with a conservative fiscal management approach — has enabled us to steadily grow during positive economic periods and also effectively weather economic slowdowns.”

The company will continue to make significant capital investments in the form new equipment and moldmaking technology, as well as human capital investments in the form of new employees, internal and external training, and other staff development. Katen says the company budgeted more than $1 million for capital purchases this year—and has targeted new hires in multiple departments to support the growth at both companies.

“Our recent growth in the medical device industry and corresponding cleanroom medical device molding continues to drive our organizational development plans,” Katen concludes. “We are looking to significantly expand our cleanroom capacity, which includes an estimated $1.5+ million capital expansion at Plastikos, with additional investments required in all related departments—including our toolroom and moldmaking capabilities and staff. We believe that the successful implementation of our strategic medical expansion will open the door for significant new project opportunities and corresponding growth for both companies.”

For More Information

Micro Mold Company, Inc. / (814) 838-3404

rkaten@micromolderie.com / micromolderie.com

Visit Micro Mold at amerimold 2013 in Booth 130!

Photography and videography courtesy of Creative Technology.

Related Content

MoldMaking Technology's Most-Viewed Content of 2024

The most popular MoldMaking Technology content according to analytics reports over the past year.

Read MoreHonoring Excellence in Mold Manufacturing

After a brief hiatus, MoldMaking Technology’s Leadtime Leader Awards competition returns to recognize outstanding performance and innovation in the moldmaking industry.

Read MoreWho Will Win the 2024 Leadtime Leader Award? Find Out at NPE 2024!

This is it! It all boils down to this. Join the moldmaking and plastics community as MoldMaking Technology discloses this year’s award winner at 4 p.m. tomorrow in the West Hall at Booth 2143.

Read MoreMoldMaking Technology's Leadtime Leader Awards Competition Returns!

After a brief hiatus, MoldMaking Technology’s Leadtime Leader Awards Competition is back!

Read MoreRead Next

Moldmaker/Molder “Doubles Down” with Technology Investment

“At a time when many others are exiting the domestic tool making business because of its low margins and ever growing requirements for capital investments, we see it as a critical component to the ultimate success of our customers’ end product in the market.”

Read More2013 Leadtime Leader Awards: Winner Tech Mold Inc.

A three-division approach, technology innovation and a grow-your-own skilled workforce allows this mold manufacturer to balance the entire moldmaking process — ensuring continued success and landing it this year’s 2013 Leadtime Leader Award Winner title.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More