Presented by Progressive Components and MoldMaking Technology.

The caliber of candidates this year was impressive. Several of our past Leadtime Leaders tossed their hats in the ring to challenge new candidates for this year’s title, and the entries offered proof that each company has experienced tremendous growth since earning their own Leadtime Leader title, even during a global pandemic that challenged, spotlighted and accelerated change for this critical niche of manufacturing.

Westminster Tool puts its people first, which got them noticed when they won the 2014 Leadtime Leader title. However, it’s the company’s technology investment that helped them take this year’s title.

The past year threw everything it had at mold manufacturers across North America—shutdowns, added safety costs and protocols, supply chain disruptions, sickness, no travel or customer access, etc. However, despite this string of setbacks, the mold manufacturing marketplace answered the call and went above and beyond. Whether with face shields, ventilators or respirator components, mold builders produced the necessary products and equipment in record lead times with the utmost quality. And our 2021 Leadtime Leader is no exception.

Westminster Tool (Plainfield, Connecticut) did its part in the fight against COVID-19, and it was the plan set in place back in 2014 that helped this team survive and thrive the past seven years since its first Leadtime Leader win, let alone the past year.

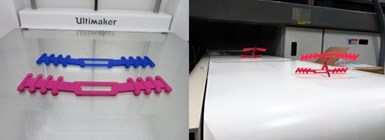

That plan includes investment in both people and technology. When the virus hit, it was the company’s investment in 3D printing that paid off. Using its new 3D printer, Westminster Tool addressed specific challenges in the community brought on by the pandemic.

For example, the company began 3D printing ear protectors to hold facemasks in place while relieving the pressure placed on the user’s ears. Increased need in the community lead to producing a two-cavity mold in one week.

Westminster Tool helped fight COVID by 3D printing and molding face mask ear protectors for local healthcare and nursing home facilities.

“We used this mold to produce 10,000 ear protectors, which we then donated to local healthcare facilities, nursing homes and other local institutions that were in need. The ear guards also allowed users to adjust and tighten masks, which proved to be a major resource with children and schools in the area,” Westminster Tool President Ray Coombs Jr. says.

This response is only one example of this shop’s adaptability, resilience, forward-thinking and passion, which earned its team our 2021 Leadtime Leader title. Most importantly, Westminster Tool’s leadership, management and workforce come together every day to work the plan and hold tight to its core beliefs—continuous learning, continuous improvement, accountability, emotional intelligence, transparency, consistent communication, a preventative hands-on manufacturing approach and a commitment to a proactive partnership.

Of course, with this past year, Westminster Tool focused a bit more on safety, but its system and culture were already in place to take what a global pandemic had to offer head on. And it was the new technologies, processes and capabilities, workforce development, training and sales & marketing aspects of the plan that helped them win this year’s title.

Westminster Tool may be familiar to you for several reasons. Not only were they MMT’s 2014 Leadtime Leader Award winner, but they were also featured a few years ago in MMT and sister publication Modern Machine Shop for the people part of their plan. It is this company’s unique approach to culture, which includes internal training programs, that has enabled this company to address the skills gap and grow.

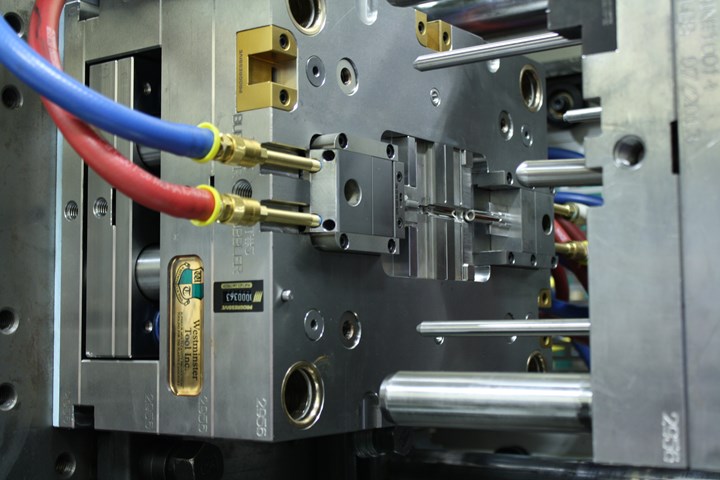

Westminster Tool specializes in manufacturing complex SPI Class 101 injection mold systems, including hot runner, unscrewing, multiple mechanical action, high-temperature/specialty applications, collapsible core, lift-n-strip, insert and prototype & bridge molds to prove out production processes.

Further, the Westminster Tool team grabbed the 2014 title for the “deep awareness of its capabilities and limitations,” which lead to a dramatic reduction in lead times, improvement in on-time deliveries, increased sales and a shift from focusing solely on toolmaking to pre- and post-manufacturing services as well. It was also due to the recognition of its people as the shop’s chief competitive advantage.

Fast-forward seven years and Westminster Tool has continued its self-awareness journey, which has helped grow the business in a very deliberate yet unique way for a traditional mold builder. Since the start of the plan, the company has nearly doubled sales and employees and is continuing to grow.

The Origin of the Plan

Westminster Tool was founded in 1997 in the basement of Founder and President Ray Coombs’ home. Ray's passion for the industry and business quickly outgrew his basement. He expanded to the company’s first full-scale facility in 1999 in Plainfield, Connecticut, where it advanced from building tool components to complete plastic injection mold systems. In this facility, the company grew from a team of six to 16 and eventually moved to its current primary location (5 East Parkway, Plainfield, CT 06374) in 2006.

The company again expanded its capabilities to deliver a complete mold-building experience for customers in this facility, including a technology center for in-house tool validation, tool sampling and low-volume part production.

Westminster Tool designs and builds injection mold systems as well as produces injection-molded high-performance thermoplastic components for technically demanding applications in the medical, consumer products, packaging and automotive/transportation markets.

For most of Westminster Tool’s history, it has predominantly served the plastic injection mold industry, including automotive, packing and medical markets. In 2008, Westminster Tool had a unique opportunity to resolve a challenge for a complex aerospace component, which led to the expansion of business capabilities into high-performance material production, resin transfer molds, composite tooling and engineered applications.

Then in 2013, Westminster Tool launched the plan. Part One was making a cultural shift to address the skills gap. For the next five years, 100% of all capital investment went into people, training and personnel development. This included adopting lean principles, creating a digital internal training academy, enhancing and adopting new company metrics and emphasizing emotional intelligence. During this time, the company purchased a second facility (51 Industrial Park, Sterling, CT 06377) to host classrooms, an employee gym, storage and a convenient way to expand capabilities for specific projects. Since the plan was put in place, the people side of Westminster Tool has grown from 24 to 38 employees with a decrease in the average age from 35 to over 50.

In 2018, Part Two of the plan kicked in and shifted to the technology side of the business, from which investment has paid off with tooling sales that nearly doubled and drastically improved efficiencies. Then Westminster Tool rebranded the company to reflect its cultural and technological changes and invested heavily in bringing its equipment and facilities up to date. And the company didn’t slow down. It also expanded the sales team to work in conjunction with the engineering team to bring projects from quote to purchase order to job processing more efficiently, hired a digital marketing strategist and established a marketing team.

The Evolution of a Plan

Today, Westminster Tool focuses on solving complex manufacturing challenges for the aerospace, medical and consumer packaging industries. Its team specializes in manufacturing complex injection mold systems, composite tooling and high-performance component production and is committed to lean process development, automation, process monitoring and control, process optimization and specialty post-mold operations.

Westminster Tool also offers injection molding and value-added operations such as precision machining, extruded thermoplastics, stock metals, castings, forgings, 3D-printed metals and thermoplastics, component assembly, adhesive bonding, electrical testing and plasma treatment and specialty coatings.

A thorough, proactive and hands-on process for all of its moldmaking and pre-and post-manufacturing services allows Westminster Tool to inject itself early in projects, creating true partnerships with customers to develop unique manufacturing solutions.

“While we have enhanced service offerings to include pre-and post-manufacturing services, we have not lost sight of the importance of building high-quality injection molds that will provide in-spec, dimensionally stable parts shot after shot,” Ray says. “Our thorough, proactive and hands-on process enables us to get involved at the inception of a project and partner with our customers to provide a manufacturing solution as unique as the challenge.”

Dedicated employees are passionate about improving the company’s manufacturing processes to incorporate the latest technology and innovation to deliver value to customers. “We are a young, curious, accountable and fun team of around 40 people,” Ray says, “but those same people are part of a versatile technical design team that is driven to improve product speed to market, meet cost-driven product requirements, provide comprehensive risk analysis and mitigation and offer complete technical support resources.”

New Technologies, Processes, Capabilities

Westminster Tool is also committed to lean process development, automation utilization, palletization, unattended production and high-speed machining holding tolerances of ±25 microns for various complex SPI Class 101 injection molds. This commitment relies on the right technology and training the team on that technology.

Westminster Tool invested 12% of sales into high-speed mills and custom robotics throughout the CNC department in 2020.

In 2020, 12% of sales were invested in technology such as higher performance, high-speed mills and the expansion of custom robotics throughout the CNC department. When asked what technology investment has impacted operations the most, CFO Colby Coombs relays a story to explain: “During 2020, we identified a need to expand our milling department to increase our current capabilities and our throughput per person. So we invested over 10% of our annual revenue back into milling equipment by purchasing a Haimer shrink-fit system, Mikron HSM 500 Moldmaster graphite mill, Mikron mill S 500 LP, Mikron HSM 400U LP five-axis milling machine and a wire EDM.”

A need for more milling capacity resulted in the purchase of a Haimer shrink-fit system, Mikron HSM 500 Moldmaster graphite mill, Mikron mill S 500 LP, Mikron HSM 400U LP five-axis milling machine and a wire EDM.

This significant investment not only doubled machining capacity but is already making a major impact on how Westminster Tool does business. By adding more high-speed milling machines, the company can now process more work in-house and bring on more intricate and complex jobs.

“The new automation capabilities of the equipment are also expected to increase unattended time and decrease lead times,” Colby says.

New EDM technology doubled EDM capacity while improving cross-training efforts.

Before all this technology investment, the floor had two wire EDMs in the CNC line. One was entirely dedicated to supporting the production department. With the purchase of the new wire EDM, the shop moved one into the production department, leaving two for the CNC line.

The right technology and training—automation, palletization, unattended production and high-speed machining—helps Westminster Tool hold tolerances of +/-25 microns for various complex SPI Class 101 injection molds. These new automation capabilities are increasing unattended time and decreasing lead times.

“This not only doubled capacity in our EDM department, but our production department now includes a wire EDM and high-speed milling machines so that every trainee will receive milling and wire EDM training to better support cross-training and their future transition to the CNC line,” Colby says.

This intentional benefit is where people and technology meet: training, specifically hard mill training. By freeing up more machines in the milling department, experienced machinists now have more time to train and cross-train other Westminster Tool employees without interrupting workflow.

“Cross-training has been an instrumental way for our team to learn new technologies and enhance our processes by exposing us to different challenges and perspectives. It is one of the many ways employees can embody the dynamic quality we look for in employees,” Ray says.

New machines mean better training. Experienced machinists have more time to train and cross-train other Westminster Tool employees without interrupting workflow.

Westminster Tool requires each employee to be cross-trained in at least one additional skill set or operation within the company. Not only does it enable the team to better adjust to customer demands, but it also gives employees alternative insight into the shop’s process. In another example, an engineer who learned how to mold parts applied valuable lessons learned in the next tool design.

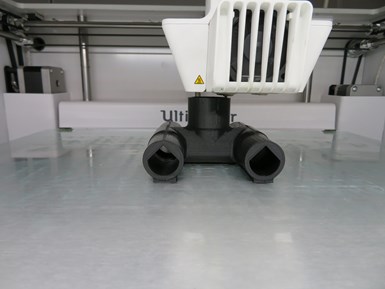

With its Ultimaker desktop 3D printer, the team prints a replica of a final molded part and develops inspection methods and fixtures before the real part is molded, reducing manufacturing leadtime.

With 3D printing also front of mind, Westminster Tool invested in an Ultimaker desktop 3D printer to research strategies for entering the additive manufacturing (AM) space and rapid prototyping to print a replica of a final molded part to develop inspection methods and fixtures before the real part is molded.

“This approach allows us to physically test our inspection methods quickly and with little cost so that upon molding, there is a seamless transition into the verification process,” says Vice President Hillary Thomas. “This reduces our manufacturing lead time and helps us exceed our customer expectations.”

Westminster Tool partnered with Mantle in 2019 to support the research and development of 3D metal printing capabilities. Throughout 2020, Westminster Tool invested in this new technology to support this development effort to launch Mantle's new TruShape technology in 2021.

“Through this partnership, we are slated to purchase a beta machine for 3D metal printing this year,” Hillary says.

Workforce Development and Recruitment

With part of its plan focused on people, hiring is on target, according to Ray. Westminster Tool’s most effective strategy for recruiting new employees is a model focused on growing employees and helping them achieve their most significant potential.

“This has proven to be a large differentiator in the marketplace of recruiting new talent because people value being able to grow,” says Talent Development Coordinator Hannah Coombs. “It also makes Westminster Tool an attractive prospect for those entering the manufacturing workforce for the first time and those with experience levels of all kinds. Our motto is ‘we hire for character, train for skill,’ and it’s something new hires recognize and value.”

The shop also uses a network of “champions” at the surrounding technical high schools and colleges. These are faculty that know Westminster Tool, its mission and the types of careers it offers. By identifying those within these schools who are passionate about helping students and value Westminster Tool’s business model, the company can identify ideal candidates and provide a more direct pipeline of local talent.

To continue this success with its educational partners (see Recruiting Talent sidebar), the Westminster Tool team constantly volunteers to be a resource for curriculum development, tours, job shadows and more.

Continuous Learning

Westminster Tool takes “team” to a whole other level. The company’s 38 employees are the core of a culture of continuous learning and continuous improvement.

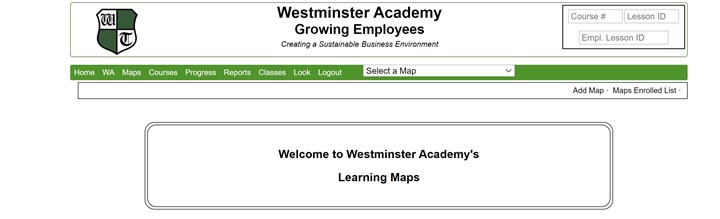

Westminster Academy—an internal training program—is key to Westminster Tool cross-training and growing talent from within to support the growing needs of the shop and customers.

“Our success has been in part to our ability to cross-train and grow talent from within to support the growing needs of our shop and customers. While external training sources do provide us with some of that training, a majority of our hands-on training uses our internal training program, called Westminster Academy,” Hannah says.

This training program, developed internally, relies on a player-coach model. Experienced employees act as coaches when fulfilling a trainer role, and those without experience as players when acting as the trainee. Together, they create their training documents based on their collective experiences and skills to support Westminster Academy and track their learning progress via “maps.”

Westminster Academy maps outline a specific career pathway in the company with all the courses and lessons needed to succeed in that position. With more than 50 maps covering positions from “Molding Technician” to “President,” everyone within the company participates to clearly define the roles and responsibilities required of their position and to ultimately improve their maps for the next training opportunity. This captures and standardizes all tribal and technical knowledge for current and future trainees, ensuring everyone receives the same quality training.

Westminster Academy uses maps to outline specific career pathways within the company that include all of the necessary courses and lessons for the employee’s success.

“These maps are constantly growing and improving as we shift roles or meet new challenges,” Hannah says. “Westminster Academy has recently undergone a major revamp and currently has more than 5,000 unique lessons in over 600 courses, all designed to help trainees succeed and reach their greatest potential.” Everyone is expected to improve their maps as they go through training by adding new lessons, removing lessons that are no longer relevant and developing training documents.

Sales and Marketing

You can’t undergo this level of transformation and not get the word out, right? So part of the plan was a company rebranding in 2018 to focus more on Westminster Tool’s culture and quality offering, which included developing an entire marketing strategy that they did not previously have (see Developing and Enhancing the Brand sidebar).

“To strengthen our brand and better support sales, we have established an internal marketing team including a digital marketing strategist. This has been instrumental in executing some of our initiatives in 2020, including becoming more focused on digital marketing due to COVID-19’s impact. We have been hosting webinars, conducting virtual tours and a virtual open house event, and after the realization that in-person trade shows would be on hold, we hosted a Caffeinate and Connect Series of virtual face-to-face meetings with our customers and suppliers instead of attending trade shows,” Hillary explains.

Westminster Tool has prioritized setting quality standards within the sales department and identifying risks early in the quoting process to be better informed and prepared for projects. The company is also incorporating design into the sales process as early as the quoting phase.

Customer service is what measures success at Westminster Tool. The team collects, reviews and logs feedback and metrics in daily morning team meetings.

“We are now able to start a project with some design challenges already addressed to shorten lead times and get projects through job processing and onto the shop floor sooner. This requires our sales team to have more technical design knowledge, which is why we have combined our sales and engineering teams to promote cross-training between design and sales,” Hillary says.

Utilizing the feedback continuously gathered by both the sales and engineering teams, Westminster Tool has made numerous improvements to the customer experience. “Many of these changes are driven by better delivering on our value proposition ‘Your Challenge is Unique…So is Our Solution,’” she adds.

The changes have allowed the team to better identify risks upfront and present strategies to mitigate and manage these risks to deliver timely and cost-effective solutions. These include revamping the quoting process to provide more accurate and competitive pricing, enhancing the project management system to have complete project risk management and integrating a “Lessons Learned” meeting both internally and with the customer to close the loop on ways to improve for the future.

The Plan Goes On

In the end, it's all about the customer, and here at Westminster Tool, it’s all about welcoming each customer into its house. “As a guest in our house, we believe in the mantra: If you succeed, we succeed. Your project carries our brand stamp as well, so this means we will be proactive in identifying potential challenges and we are committed to overcoming risks together,” Hillary says.

This demands open and frequent communication, and the Westminster Tool team is committed to consistently providing healthy dialogue exchanges between OEMs, contract manufacturers and toolmakers.

“Customer service is not only built into the way our individual teams measure success but is also tracked to measure the success of the company as a whole,” Ray says. All of the feedback and metrics collected are reviewed regularly, shared and discussed in morning team meetings, and then logged as learning opportunities for the future.

For example, Westminster Tool requests and documents customer feedback after each stage within the sales process (quoting, order acceptance, design, manufacturing, validation, etc.) and after completing each job within one month of shipment. Each employee is expected to document a minimum of one piece of feedback per month, in addition to feedback on every job. This is documented in the company CRM and maintained in a Customer Service Metrics Report (an internal KPI tracking document) which also considers returned products and nonconformance reports as part of the shop’s key customer metrics.

One particular change that came out of customer feedback was how the team presents challenges and possible solutions. Historically, the team engaged the customer to identify solutions, but after receiving feedback, the team now offers two to three options from which the customer can choose. This solution has received great feedback from customers who value direct communication and the simplicity of decision making.

Winning the 2021 Leadtime Leader Award only reinforces that the Westminster Tool plan is working, so this team plans to continue investing in training and technology to improve on-time delivery and quality even more.

“Taking shortcuts to meet or exceed a delivery requirement is not our standard. Instead, we try to demonstrate to our customers the value of following our proactive process, which addresses challenges upfront versus on the back end during validation/etc. This process places a large emphasis on quality as the top priority,” Hillary says.

This is why even though the shop’s on-time delivery rate is 88%, it only has a 3% rate of rework for its products. However, Westminster Tool’s on-time delivery is increasing. Currently, it is 3% higher than it was in 2019. This is part of a rising trend over the last four years, rising consistently since 2017 when the company was at a 41% on-time delivery.

During this time, the shop used value stream mapping and other lean principles to identify areas of waste within its process. The team also adopted an employee work schedule with a “two-day look ahead,” requiring all employees to document their scheduled tasks at least 48 hours in the future. This practice ensures every team member at each step in the manufacturing process is aware of any potential challenges and can mitigate risks before becoming a problem.

Another vital aspect of continuous improvement is the daily improvement meeting. Every morning, the company spends 20-45 minutes working on the business in functional improvement teams. These teams are tasked with regularly communicating needs, challenges and discussing general workflow. The challenges and ideas presented in these meetings are logged in a Continuous Improvement matrix, a digital tool in tracking challenges and solutions. Challenges are also broken down and discussed further in a comprehensive Define, Measure, Analyze, Improve and Control (DMAIC) process, a structured lean practice aiming to define challenges and implement solutions.

For example, one solution stemming from these morning meetings includes changing how the team tracks metrics, saving an additional 30 minutes weekly. Another employee at a morning meeting presented an alternative storage system for electrodes, which saved two to five minutes per shape. “Every idea documented, every solution implemented, every conversation about improvement brings us closer to our mission, and that’s how we’ve been able to grow,” Ray says. “We’ve grown because our systems work.”

As the Westminster Tool team looks to the future, the plan continues. That means more investment in training and the latest equipment to improve on-time delivery while keeping quality the top priority. I'm sure (even though they won’t say it out loud), winning the 2021 Leadtime Leader Award title was definitely part of the plan!

Related Content

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreTop 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreMaking Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreRead Next

Mold Builder Tools Up to Produce 10,000+ Ear Protectors

Since learning how Westminster Tool was embracing change, leading and communicating during COVID-19 a few months ago, I found out that they tooled up to support their local community with ear protectors too.

Read More2014 Leadtime Leader Awards Winner: Westminster Tool Inc.—Bridging the Gap without Losing Focus

A strong sense of self and a focus on people enabled this mold manufacturer to rapidly expand pre- and post-manufacturing services without getting overwhelmed by its own growth.

Read MoreWestminster Tool Rallies for Mental Health Awareness

Injection mold manufacturer and EAMA members come together to fundraise and support resources for mental illness, in honor of Mental Health Awareness Month.

Read More

.jpg;maxWidth=300;quality=90)