EDM Technology Leads in the Race to the Finish Line

Mold shops should look to race shops for technologies and strategies to help reduce their mold build leadtimes.

When you think of NASCAR Nextel Cup racing and the moldmaking industry there seems to be no obvious common thread between the two. One is in the business of sports and entertainment, and the other in the manufacturing of tools for consumer and industrial products.

The ways and means of preparing racecars and the building of molds has dramatically changed for both race mechanics and mold building engineers. Technology has advanced in the last 30 to 40 years where CNC machines are now the tools that we depend on to provide components with higher accuracies, repeatability, quality and even unique parts that were never possible before.

Wire EDM Makes a Difference at Penske/Jasper Engines Facility

EDM technology now plays a very important role inside the race shop of Penske Racing South (Mooresville, NC). In previous years conventional machining methods were used to manufacture various parts in the race shop and engine building department. Having highly skilled people with years of experience is the key to the success of any race team.

On Sunday afternoons you see the #2, #12, #77 Dodge Chargers driven by Rusty Wallace, Ryan Newman, and Travis Kvapil race down the backstretch at 190 mph with their engine revving at 8,500 rpms or more. The people you don't see are behind the scenes back in the shop running the equipment and assembling the engines with precision tolerances.

The new state-of-the-art Penske Jasper Engine shop located in Concord, NC, has been using a wire EDM since 2001. Various engine and car components are now done with wire EDM using a single tool—the 0.010" diameter wire. Parts are loaded in the EDM and run unattended overnight and are finished in the morning—each part identical to the one before it. With previous methods it was difficult to produce some specialty parts with the same tight tolerances. "A sound engine program is the heart of every successful racing team," says Scott Corriher, engine shop manager at Penske/Jasper Engines (see Figure 1). "We need to provide engines for three race teams over a 36-week race schedule—including practice sessions. It's not a secret if I say that things can get pretty busy around here. We like the fact that the wire EDM is capable of running unattended overnight helping to keep the flow of production moving," says Corriher.

Renault Formula 1: Being Able to Show Some Imagination

Compared to NASCAR, Formula 1 racing has less stringent guidelines and rules on how, what and where you can modify the racecar. NASCAR's rulebook does not allow special modifications or custom components in the engine or chassis design. NASCAR's goal is to make sure the cars are safe and have a field of 42 cars each week that are all competitive. NASCAR race teams are scratching to find any slight advantage in horsepower or handling while staying within the rules. With Formula 1 Racing, there are almost no limitations.

"EDM opens up new horizons at Renault Formula 1," states Jeff Fullerton, machine shop manager. Together, its various features mean that right from the design stage, not only can new machining methods be thought of, but also the part can be given new characteristics to improve it.

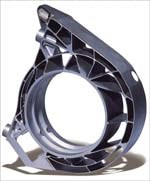

This Renault Formula 1 rear upright (see Figure 2) previously was made up from 10 separately machined sections, which were then welded together using a highly complex assembly jig and took a total of 57 hours to manufacture.

The rear upright has the following functions:

- Holding the axle

- Mounting the disc brake caliper

- Suspension mounting points

- Wheel speed sensor

- Ventilating the disc brake cooling system

- Mountings for the disc brake cooling system pipe work

Today using EDM, it is made from a single block and only needs 40 hours to manufacture. With around 40 units made per season, the total time saving is 560 hours. In addition, the part is lighter because it is manufactured from a single block; it is even stronger, which means that the sides could be made slightly thinner. Using titanium—which is recognized as a light material that is easy to cut using EDM but difficult to work with by traditional machining methods—also reduced the overall weight of the part.

"The taper angle machining range is higher than other machines. From our experience, this is the only way to make suspension uprights in one single piece," says Fuller. "Thanks to Charmilles Technologies EDMs, race builders can put new ideas into practice overnight, if necessary. They can try all kinds of alternatives until they find the best one."

One other F1 racing team invested in a wire EDM to produce its racing gears in-house. The technique dynamically demonstrated its advantages by producing a more accurate, lighter and stronger gear with a leadtime of days instead of weeks.

Wire EDM: From the Race Shop to the Mold Shop

The same principles used by race shops can be used in the mold shop. For moldmakers the wire EDM also is a perfect solution for manufacturing precision components for molds and dies with high accuracy and surface finish tolerances. The Charmilles Robofil 440cc (see Figure 3) with its large UV travels permits tapering of 30 degrees up to part heights of 15.75' tall.

For extrusion molds wire EDM is used exclusively for its taper capabilities. It is known that die sinking EDMs are used extensively in the building of a mold using electrodes to burn the cavity shapes; it also is known that the life of a mold is not forever. By replacing a worn or damaged section with an insert that was wire EDM'ed, the customer can get back up and running quickly. A mold that is designed with cavity inserts is cost-effective and allows you to provide better customer support. For end users that are in remote locations, not having to ship the mold back for repair is a real benefit.

Many mold shops are using wire EDM technology as a tool to machine various components and cavities related to the mold. In some cases the entire mold design can be designed around the wire EDM process (see Figure 4). Wire EDM can be used to machine open cavities to receive inserts; core inserts (with complex shape); open cavities with sub insert on the bottom; openings to receive inserts; mechanisms to operate the mold; electrodes (honey comb or rib shape); lifter pin with complex shape; and ejector pin holes.

Steve McDonald is the EDM foreman at American Tool and Mold (Tampa Bay, FL). "It seems to me that all shops in some way have something to offer in general. There are a lot of similarities, so what you should focus on is where to find the slightest edge. Competition here is the key element," says McDonald. It doesn't matter if you are a mold shop racing to compete in a global economy or if you are a race shop trying to keep your car at the front of the pack on Sunday … either way it's wire EDM that can lead to making both a success.

"We recently finished a medical project that had a size and positional tolerance of plus or minus .0001. Prior to the wire EDM, this job would have had to be broken up into many grindable inserts. Instead with the accuracy of our Robofil 4020 and Robofil 4030SI-TW, we were able to design the tool with replaceable modules and interchangeable inserts with four cavities in each. Another added feature is that with the automatic wire threader we were able to get more than 40 hours of unattended run time before changing parts in the machine," states McDonald.

Race shops and mold shops are faced with the same question. How do they stay competitive? The answer is by making components more accurately with wire EDM, building them faster, reducing costs, and improving the quality and reliability. Whether the sign out front says race shop or mold shop, the answer from the people inside is always the same, "Before having the wire EDM, we never thought about changing from our conventional machining methods and our way of doing things. Now we are able to re-think and re-design components opening up a new world of opportunity for our business operation." So, if you haven't yet analyzed to see where a wire EDM might fit in, now is the time. It could prove to be an integral part of your

Related Content

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreRead Next

Wear Parts and Consumables: The Keys to Maximizing Your EDM

Mold shops need to pay attention to the potential impact wear parts and consumables can have on their overall production.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More