Keeping Your Mold Shop Competitive

To remain competitive in the mold manufacturing market every mold shop needs to answer three questions about its diesinker EDM.

The time it takes to produce a mold has been reduced in the last few years. Customers of mold houses have been demanding that molds be produced faster and more efficiently so the product reaches the market more quickly. In response, some EDM manufacturers have introduced new diesinkers that cut faster. However, is this all a mold shop needs today?

In the midst of a challenging economy, mold shops have been forced to look for new ways to compete, not just with American mold shops, but also with competition overseas. This debate is pervasive among builders. Is speed all that's required for a diesinker to be competitive? The need to remain competitive has prompted mold shops to consider other factors more closely than ever, such as features and control capabilities of a diesinker. Following are three questions every mold shop needs answered in order to determine the necessary considerations when purchasing a diesinker EDM.

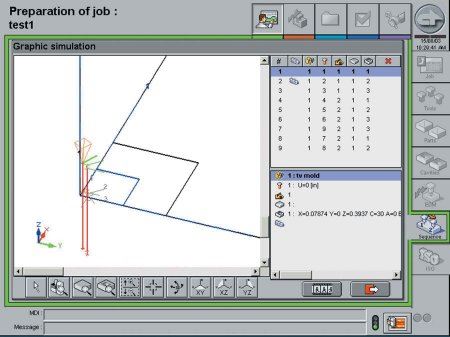

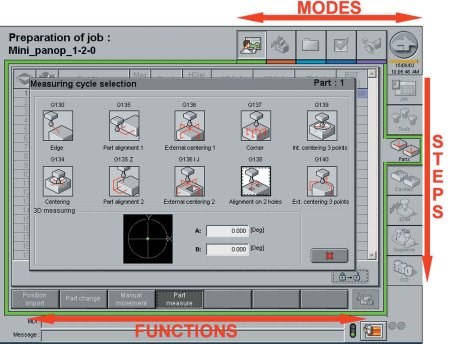

1. Is this control easy to understand and navigate?

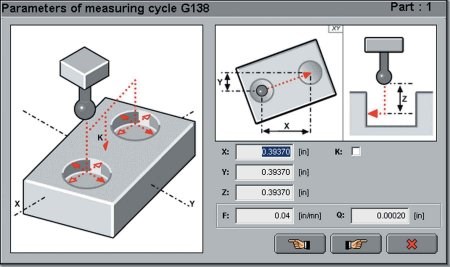

Most controls found on CNC diesinkers can perform the general tasks that are required to produce molds; however, user-friendliness and navigation have become greater concerns. As more and more operators retire, a new generation of operators joins the ranks-a generation trained on Windows-based PC systems, resulting in the need for builders to redesign their controls-bringing greater benefits to the customer. PC Windows-based operating systems offer an easily understood graphical interface that is easily navigable. Some EDM manufacturers have gone so far as to include the operating, maintenance and part manual on the screen. These manuals use a web-type browser, which incorporates images with the text and simplifies the research/inquiry process.

2. Will this control communicate with other equipment in the shop?

In this day and age, a diesinker must produce more per day than ever before, and automation is one way to increase productivity. Manufacturing a robot is not a problem for most EDM manufacturers; however, the robot does not complete the automation process for most diesinkers. In addition to the robot, many customers discover they need a control that can incorporate other equipment such as a CMM, as well as other PCs for monitoring and programming. Today, the most efficient way to locate workpiece locations on pallets and electrode offsets is to use a CMM. To fully automate the process, the CMM must then communicate this information to the EDM diesinker control for each of the jobs in the robot or in a toolchanger. Another way to maximize a diesinker is to know the status of the machine at all times, which can be accomplished using a machine control that can alert the operator with detailed information as to any malfunctions through either phone or e-mail.

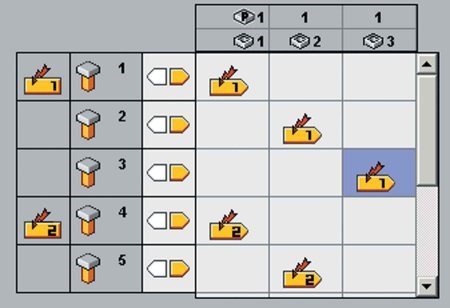

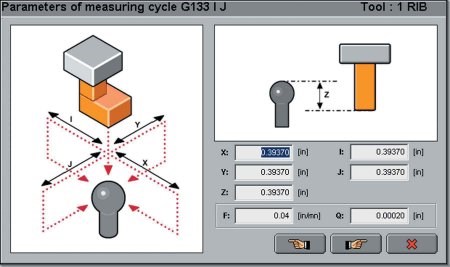

3. Can this EDM diesinker help me organize electrodes and workpieces for easy to complex jobs?

Typically, controls help the operator calculate the correct generator settings for a burn. However, few controls can truly program everything required to complete a job. One benefit offered by more advanced controls is the ability to assist in the organization of electrodes and workpieces. Once the information for a particular job has been obtained, these controls can suggest the best course of action to produce the job. Should the operator determine that this course of action needs adjusting, the control can then assist the operator with adjustments.

The next time you're in the market for a diesinker, consider the speed at which the machine burns ribs, cavities and subgates. However, don't overlook the importance of an advanced control. You might just find a Windows PC control with features and options that your operator or future operators will use to keep the machine burning, and in turn, keep you competitive.

Related Content

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreRead Next

How Trends in Diesinking EDM are Benefiting Moldmakers

Turnkey solutions that provide automation in a more affordable and easy-to-implement package are available for today’s mold manufacturers.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More