EDM Efficiencies Excel

Advancements in EDM processes in terms of machining speed and surface finish improve overall accuracy, productivity and profitability.

The reemergence of reshoring has mold manufacturers continuing to seek out ways to improve surface finishes and accuracies while reducing cycle times. Keeping your EDM department up to date with the latest in machinery and technology is one way to do just that. A roundtable of EDM manufacturers and suppliers discuss common questions mold manufacturers ask as well as the latest advancements in EDM technology—in the areas of EDM automation, faster speeds, power supply and control units, wire threading, electrode materials, programming and software. .

EDM Queries

According to Isabel Florence, Marketing Manager, Sodick, Inc. (Schaumburg, IL), the majority of moldmakers’ requests revolve around improving their own productivity. “They want to EDM faster with less electrodes, achieve a finer surface finish to reduce or eliminate polishing time and add automation (loading systems) to machines to increase unattended machining hours,” she states. “And, moldmakers involved in manufacturing micro molds would add the need to achieve finer feature definition—including a smaller-corner radius.”

Automation challenges are also addressed at Methods Machine Tools (Sudbury, MA). National Sales Manager Steve Bond notes that the company receives inquiries from mold manufacturers across the U.S., Canada and Mexico about how to reduce labor costs and increase spindle run times. “They want advanced automation solutions which combine several technologies—such as EDM; five-axis, high-speed milling and in-process inspection,” he comments. “Requests include the ability to transfer parts across a multitude of machining platforms in an effort to reduce total cycle by minimizing handling and maximizing efficiencies.

“Many moldmakers already run quite lean as it relates to labor, so they need solutions to increase production and further reduce delivery time with their current labor force,” Bond adds. “Combining machining platforms, reducing handling, changeover time and inspection—all while maximizing spindle runtime—are topics when we talk to our customers.”

Similar queries are fielded by Gisbert Ledvon, Business Development Manager, GF Agie Charmilles (Lincolnshire, IL). Ledvon notes that moldmakers often ask the company how they can improve the efficiency of their EDM processes via programming and automation.

Greg Langenhorst, manager of EDM sales engineering at MC Machinery Systems / Mitsubishi EDM/Laser (Wood Dale, IL), adds the most common question he is asked is, “What are you, Mr. EDM Manufacturer, doing to help us reduce our cost of operation?”

Time is also of the essence at YCM Americas (Santa Fe Springs, CA)—a recent player in the EDM market. Charlie Quillen, Product Manager for the EDM unit, notes that on the wire side, the company’s customers want to know how large of a taper can they cut, what kind of a surface finish be achieved, and how fast can these processes be accomplished.

Over at graphite electrode manufacturer Ohio Carbon Blank, Inc. (Willoughby, OH), General Manager Dale McCartney says that the majority of their customers’ requests are focused on the best materials for EDM of non-ferrous materials. “These questions are typically raised when a ‘steel EDM’ mold shop is required to EDM exotic or foreign materials that they are not familiar with,” he explains. “The materials in question might include: Inconel, stainless steel, aluminum, Ampcoloy®, Moldmax, titanium, beryllium copper, carbides and others.”

McCartney emphasizes the company tries to make sure the moldmakers understand the possible issues that surround the EDM of these materials. “Depending on the material, considerations must include: electrical conductance, heat transfer and often much longer EDM cycle times when compared to EDM of standard steel alloys,” he notes. Additionally, McCartney recommends mold shops consult their EDM machine manufacturer’s recommendations for proper machine settings and the latest software update. “Depending upon the age of the EDM machine, the latest software technology update can provide a significant increase in efficiency and reduce cutting time,” he says. “The machine settings, which often require experimentation, are typically the most important aspect of achieving maximum productivity.”

Technology Advancements

Big jumps in machining efficiencies—both in milling and EDM—are being seen at Methods machine Tools. “For example, one of our machine tool partners continues to develop extremely fast controllers capable of surfacing in not only three-sided, but up to five-sided mold components and electrodes. Tooling manufacturers, along with software companies, have joined forces to advance their technology offering to take advantage of the higher feedrate and RPM capabilities. Spindles capable of speeds in excess of 40,000 RPM to as high as 90,000 rpm are going to change the way molds and components are processed in the coming year and beyond. Gone will be much of the ‘heavier is better’ thinking and more focus will be put on lighter cuts at higher feed rates and finer finishes.”

Bond adds that controlling these speeds and the heat associated to the increased RPMs and feedrates are challenging to machine tools builders, but notes that leading machine tool builders are spending most of their time, energy and money developing machines that will take mold builders to new levels of productivity in the years ahead.

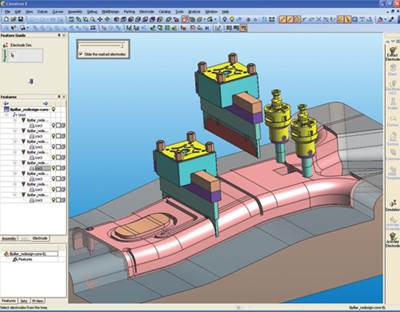

Productivity is also paramount at GF Agie. Once again, Ledvon emphasizes the increasing importance of automation in EDM part processing, as mold manufacturers look to streamline their efforts and improve their overall accuracy, productivity and profitability. “Planning and setting up EDM jobs can be very time consuming as several criteria are involved, such as part locations, offsets, over burns, the number and order of electrodes used in the job, finishes and flushing,” he says. “As a result, I see more EDM companies developing new advancements that will streamline these processes for moldmakers.

“Moldmakers often want to troubleshoot and/or enhance burn cycles when working with exotic materials—such as beryllium, copper and high-carbide content tool steel—through modified parameters that speed up the EDM process without making it unsafe or creating conditions that can be detrimental to a workpiece material’s integrity,” Ledvon continues. “Therefore, more EDM companies are starting to incorporate new technology into their machines for effectively handling such ‘non-standard’ materials and applications.”

Faster speeds are at the top of Sodick’s list of advancements as the company continues to advance its linear motor technology in combination with advancements in motion control and power supply capability. “With its high speed, high acceleration (up to 2G), and vibration-free precision, linear motor technology provides the base technology platform to improve the EDM process in terms of the machining speed and surface finish improvements that are unachievable with conventional ball screw drives,” Florence explains. “During the next 12 months we will introduce a further motion control advancement that will improve further interpolation speed and accuracy.”

According to Florence, this development allows additional improvements to the company’s arc-less machining function, which will improve machining speed (up to 25 percent) and reduce electrode wear to below (.05 percent). For Sodick WEDM models a similar development path will improve machining speed and achieve finer surfaces. For example, a target surface finish that previously required four passes will be achievable in two. “These advancements will reduce the EDM machining time for moldmakers, improving their productivity and as a result their capacity,” she notes.

Over at MC Machinery/Mitsubishi, machines are available with newly developed power supply and control units. According to Langenhorst, benefits include process quality with higher removal of material with smaller gap dimensions and low electrode wear; reduced process times by up to 50 percent, and optimized behavior of erosion and jump time, which reduce both burn time and electrode wear drastically.

On the sinker side, MC Machinery/Mitsubishi has been working on a new power supply aimed at reducing electrode wear while improving machining speed and providing an improved surface finish, Langenhorst notes, in addition to more options for high-speed, multi-axes jumping, improved finish and power consumption reduction.

Additionally, the development of a cylindrical drive system with optical drive system (ODS) technology, will add efficiency to EDM operations, Langenhorst continues. “This is a new form of linear drive. A linear shaft motor places the permanent magnets into a stainless steel shaft and moves the forcer coils into a single unit surrounding the shaft,” he elaborates. “The shaft can then use 100 percent of the magnetic flux—a full 360 degrees around the permanent magnets. This is a much more efficient system as compared to a flat plate type linear drive, as it only exposes half of the magnetic flux to the face of the coils, which then require more energy to generate the same movement, which in turn generates more heat.”

Additionally, a new generator technology on GF’s die-sinking EDM machines “drastically reduces electrode wear at faster machining speeds than do other low-wear applications settings.” The technology practically eliminates wear by building a protective layer onto graphite electrodes, maintaining their edges and detail capabilities throughout the entire process, which is especially beneficial for electrodes used to produce the same cavity shape multiple times, Ledvon adds.

Furthermore, in instances where it used to take three or four electrodes to produce a complex mold cavity with multiple ribs, this technology can reduce that amount to one, maybe two electrodes, Ledvon says. “Such a scenario brings forth major cost savings with less money spent on milling additional electrodes--especially ones with highly complex shapes. The more detailed the electrode, the more the savings.”

YCM’s Quillen adds that advancements in power supplies have resulted in much better surface finishes as well as a decreased recast layer.

MC Machinery/Mitsubishi has been working on addressing several issues relating to improving accuracy, improving wire threading over a wider range of applications, providing a larger work area without taking up more floor space, and reducing operating costs which combines energy consumption and consumables. “In both the wire and sinker EDM cases these advancements will allow mold design to better use the EDM process because of the increase in cost effectiveness,” Langenhorst says. “ Some parts that are currently being milled or ground because EDM is too slow or costly, may now enjoy the benefit of being machined by EDM which is a burr-free, unattended process.”

Ledvon of GF Agie sees automatic wire changers becoming more popular amongst moldmakers because this technology can boost productivity and reduce production costs by no longer having to manually switch between different wire diameters and types. “Moldmakers can easily switch between different wire diameter sizes and types—optimizing both roughing and finishing operations and reducing production costs,” he says. “For example, a moldmaker could use a larger diameter, less costly brass wire for rough passes where the emphasis is on high stock removal, then a smaller diameter wire, which is often more expensive, for intricate details and fine finishing passes.”

Over at AccuteX EDM (Mason, OH), Vice President Pete Intihar sees three-pass technology gaining in popularity, which according to Intihar, reduces the number of passes required to achieve the surface finish and accuracies that normally took additional passes. “This will save time, conserve energy and reduce wire consumption costs,” he states.

Advancements in electrode materials include the introduction of bonded graphite blanks, Ohio Carbon Blank’s McCartney notes. “This patent-pending technology combines a low density EDM graphite for workholding (the ‘backer’) with a high density graphite (the ‘burner) for the blank’s contact area,” he explains. “This technology has significant cost savings advantages, including the efficient use of costly high density graphite for the burner; optimized low cost material and sizing of the backer; no milling of the backer for specific workholding as it can be purchased to size; out-of-the-box ready decreases graphite blank leadtime requirements; and reduced electrode throw-away cost.”

Florence of Sodick notes that the company will be releasing a PC version of its control software, which will allow the mold design or programming department access to electrode undersize and machining time data—improving electrode manufacture and shop planning.

Over at AccuteX EDM (Mason, OH), the company will introduce 3-D CAM software, which will allow the moldmaker/EDM operator the ability to see their part in solids on the machine, notes Intihar. “AccuteX will also be adding more tech files that will allow the operator to store specific files and settings,” he elaborates. “This will save time on a future job since the information can simply be called up.”

Methods is working with a software company to develop a CAM software package called CAMplete TruePath, which helps to minimize the time on the shop floor required to set up and run five-axis machined parts, Bond notes.

For MC Machinery/Mitsubishi, new sinker machines will have software improvements that allow for higher jump speeds in multi-axes (X/Y axes speed of 5 meter/min max), which will improve side burning and sub-gate burning tremendously, Langenhorst says. “Another similar software function will come in the form of a servo system designed for deep hole burning (high aspect ratio).”

Sinker advancements on the from GF Agie help improve the programming of its machines by importing data from the CAM system, including cavity locations and electrode offsets,” Ledvon maintains. “Furthermore, the machine’s entire CNC will work on a PC, allowing machine operators to easily prepare programs and technology settings right from their desktops,” he states.

Clearly, EDM suppliers are hard at work to help mold manufacturers achieve maximum productivity through streamlined efforts. Taking a hard look at your EDM department and implanting some of these advancements on your shop floor can result in accuracy, productivity—and profitability.

Video Here

Related Content

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreRead Next

How to Reduce EDM Setup from Hours to Minutes

The right software helps automate EDM setup and avoid EDM programming errors.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More