Mastercam

671 Old Post Rd.

Tolland, CT 06084 US

800-228-2877 | 860-875-5006

mcinfo@mastercam.com

mastercam.com

IS THIS YOUR COMPANY?

Video Gallery

Achieving Surface Finish Perfection with Precision Toolpaths

In this second video of our 3-part series, we break down the Mastercam toolpaths used to achieve an ultra-smooth surface finish.

Collision Avoidance with Mastercam Deburr

In the final video of our four-part series, we're diving into one of the most powerful features of Mastercam Deburr: collision-aware ...

Season's Greetings from Mastercam

On behalf of the Mastercam Team, we are wishing you a wonderful holiday season!

How to Achieve Superior Accuracy with Mastercam Deburr

In this third video of our four-part series, we're showcasing why Mastercam Deburr is the ultimate tool for precision, efficiency, and ...

As Seen On MoldMaking Technology

Mastercam Supplies the Following Products

- CAD (Computer Aided Design)

- CAE (Computer Aided Engineering)

- CAM (Computer Aided Manufacturing)

- CNC Software

- Manufacturing Automation Software

- NC Simulation and Verification Software

Editorial, News, and Products

-

CAM Code Is Key to Precision Mold Machining

The intuitiveness of Mastercam’s CAD/CAM interface streamlines training and advanced programming for intricate fishing tackle products from Venom Outdoors.

-

Ten Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

-

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

-

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

-

Cutting Tool Data Now Integrated Into Tool Library

Mastercam users will be able to import data on Kennametal’s cutting tools, including GoDrill and Kenna Universal solid carbide drills, as well as a selection of end mills.

-

Philadelphia High School Establishes Advanced Manufacturing Program

Benjamin Franklin High School was provided software, equipment and vision to assist with the program setup.

-

Midgard Inc. Tackles Tooling Challenges and Automates Production to Keep Molds Running

This Eastern Pennsylvania molder does cavity changes daily, making its in-house toolroom critical to quickly fixing mold problems.

-

IMTS 2022 in a Flash

With this still being the month of IMTS, I thought I’d highlight some of the technology mold builders have expressed growing interest in and are actively investigating, and what was on the show floor.

-

Advanced Software Features Latest Functionalities to Improve Productivity Tools Critical for Moldmaking

CNC Software says IMTS 2022 attendees will experience the latest multiaxis, mill-turn features and enhancements of Mastercam 2023 driven by industry feedback.

-

Midwestern Advanced Manufacturing Design Technology Program Presents Unlimited Career Possibilities

Advanced Manufacturing Design Technology program at Central Community College offers new facility expansion and 100 years of instructor experience to mentor students from drafting, manual machines and CNC to part, mold and die design and advanced machining.

-

2021 Leadtime Leader Award Winner: Westminster Tool—Perseverance with a Plan

Westminster Tool’s latest commitment to the plan—investment in new technologies, processes and capabilities, workforce development/training and sales & marketing—helped them edge out this year’s competition.

-

Post Processor Optimizes CNC Five-Axis Capabilities

Mastercam’s new post processor unlocks faster and more accurate “art to part” FANUC CNC capabilities.

-

AMT Launches Smartforce Career & Education Experience Digital Platform

The re-imagined and rebranded Smartforce Student Summit delivers an engaging, remote experience for college and high school students to better learn about the manufacturing industry.

-

Diversification and Departmentalization Drive Growth for Wisconsin Mold Builder

New ownership at Innovation Mold & Design (IMD) grows the company by investment in technology that serves a departmentalization and diversification, business model.

-

Machining Webinar: How to Apply Accelerated Finishing Technology

Today the moldmaking industry has access to new tools and toolpath strategies that challenge traditional finish machining approaches.

-

How to Learn Mold Design Virtually

Plastics Engineering program instructors share their strategies for successful virtual learning for hands-on injection mold design.

-

VIDEO: 2020 Leadtime Leader Award Winner: Precise Tooling Solutions Inc. — The Power of People and a Plan

The proof is in this winning shop’s three-pillared value proposition and three-phase growth plan that promotes empowers people while promoting quality product and profit.

-

CAM/Cutting Tool Combo Improves Mold Finishes

Combining CAM software, specialty carbide end mills, and reseller support optimizes existing mills for machining molds at an electrical components manufacturer.

-

A Cooperative Spirit and Uncommon Service: Baumann Tool & Die

With a philosophy of ‘being there for the life of the tool,’ Baumann Tool & Die offers molders a host of design, production and maintenance services to extend tool life.

-

Accu-Die & Mold Excels in Die Cast Tooling with a Focus on Service, Engineering, and Precision Manufacturing

Accu-Die’s highly trained workforce, well-equipped shop are key to meeting the challenging demands of die-cast mold production.

-

WEBINAR: When It Comes to Cutting Tools, It's Not About Price, It's About Performance

The dirty little secret about cutting tool cost is that it’s not about price, it’s about overall costs. Check out this free online archived webinar to learn all the details of cutting tool performance testing.

-

Mastercam Webinar Shares Dirty Little Secret About Tool Cost

Mastercam will host a webinar December 3, 2:00 pm ET, addressing the dirty little secret about tool cost and how to avoid leaving money on the table.

-

Cutting Edge Strategies for Optimizing Milling and EDM

Makino Technology Expo focuses on high-precision machining and digital technologies to advance moldmaking.

-

Makino Continues to Raise the Bar on Machining Technologies

Packed with information to help attendees advance moldmaking, and more, Makino’s Technology Expo shows the company’s commitment to its customers’ successes.

-

Moldmaking In the Heart of Europe

Culture, technology investment and industry involvement make this small Slovenian mold builder globally competitive despite a skills gap and rising labor costs.

-

Strong Design and State-of-the-Art Equipment Gives Omega Tool a Competitive Edge

Design expertise, supported by cutting-edge CNC, materials, software and inspection enables Omega Tool Inc. deliver notably robust molds.

-

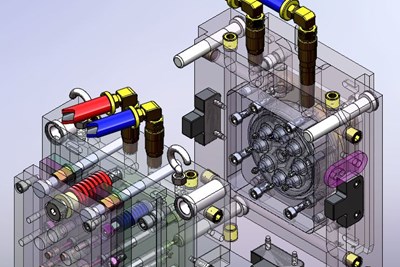

Advanced CAM Software Streamlines Solid Modeling, Toolpath Creation, Verification and Connectivity

Advanced CAD/CAM improves performance of cutting tool designs, probing, process simulation and verification and data gathering and monitoring.

-

Collaboration, Flexibility, Speed and More at IMTS 2018

Attendees walked the miles of aisles to find that IMTS 2018 delivered it all and so much more.

-

A CAD-for-CAM Toolbox Helps Moldmakers Design Better Molds

An important CAD function that a CAM package should offer moldmakers is a set of specialized CAD-for-CAM tools that focus on the machinist’s needs after the machinist opens the part file.

-

2018 Technology Review and Sourcing Guide: Software

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including software.

-

Throwback Thursday: Software Advances Push Limits of Speed and Quality

This throwback article provides interesting perspectives on software for moldmaking while also illustrating how fast software technology moves today.

-

Technology Tuesday: Featured Films

Pass the popcorn, please! This week’s Technology Tuesday slideshow is all about videos that have supplemented feature articles and case studies in MoldMaking Technology over the past year.

-

CamInstructor Expands Offering of Online Training Courses

CamInstructor offers courses in Mastercam, Solidworks and CNC Machine Programming for those who are new to tool programming and for those who are interested in refreshing their training.

-

Technology Showcase: More of What’s to Come at WESTEC

There will be so much to do and see at WESTEC 2017. If you are planning to attend, be sure to check out these products, which will be on display.

-

Leveraging CAD/CAM Advances

Often-overlooked software tools can enhance moldmaking business competitiveness.

-

Technology Showcase: Case Studies for MoldMaking

It’s time for another foray into past case study features that have been published in MoldMaking Technology Magazine.

-

March MMT Digital Edition Available

From a strategy for better mold finishes and advanced thermal control to avoiding spindle crashes and automated RFID technology, this month's issue has a lot to offer. Check out our digital edition.

-

A Strategy for Better Mold Finishes

Combining advanced tool geometry and complementary CAM tool paths can reduce finish cycle times and improve surface quality.

-

Injection Mold Inc.

This shop specializes in rapid prototype molds and “quick-delivery” production molds.

-

Small but Mighty… Talented, That Is

Every once in a while, the editors at MMT are approached by a public relations company with an idea for a mold-manufacturing-related story. Sometimes there’s something unique or intriguing about the mold building company involved, or the people who work there, that catches the eye and we just have to blog about it. Meet Emory Custom Tooling in Gilmer, Texas.

-

Project-Based Learning – The Rest of the Story

In this month’s issue of MMT, I wrote about an instructor’s strategy for teaching his mechanical engineering students about moldmaking via project-based learning. I couldn’t include absolutely everything this instructor teaches his students, so I thought I’d blog about it.

-

Project-Based Learning

University education in a shop-like setting helps mold a new generation of enterprising engineers.

-

From Marines to Manufacturers, Ready to Work

I know from personal experience early in my post-university years that veterans of our military often do not have enough highly-sought-after skills to find a good job once they are honorably discharged. Introducing Workshops for Warriors.

-

Rough Milling: Speed vs. Power

A look at what works in rough milling applications with solid carbide end mills.

-

Redefining CAM Technology for Moldmakers

Tool paths that dynamically adjust tool motion allow faster, safer machining without the need for high-speed equipment.

-

The Advantages of Getting Out of the Shop

This mold manufacturer makes a point to give shopfloor-level employees a chance to explore new technology.

-

2015 Leadtime Leader Awards Honorable Mention: Dynamic Tool & Design - Committing to a Scientific Process

This shop’s recent strides in mold qualification mirror an ongoing transition to a more systematic approach to mold manufacturing. Meanwhile, a culture of ownership ensures a full buy-in from veteran employees as well as fresh talent attracted through extensive workforce development efforts.

-

Diamonds in the Roughing

This mold manufacturer discovered significant time and cost savings in a previously unexplored feature of its CAM software.

-

A Dynamic Approach to Prototype Tooling

Software that adapts to the demands of varying cutting conditions helps this moldmaker adapt to the demands of a varying workload.

-

Managing the CAM Workforce Supply Chain

Maybe reframing the conversation in business terms will help solve the manpower problem.

-

2014 Leadtime Leader Awards Winner: Westminster Tool Inc.—Bridging the Gap without Losing Focus

A strong sense of self and a focus on people enabled this mold manufacturer to rapidly expand pre- and post-manufacturing services without getting overwhelmed by its own growth.

-

Sustainability vs. Growth

Sales volume is not the metric by which Harbec measures its progress; sustainability is. At Harbec success and sustainability are synonymous, and it is an outlook that permeates every aspect of this business. Harbec is evidence that manufacturing can be clean and environmentally friendly, and that computers and CAM systems are a toolmaker’s best friends.

-

CAM Can Help You Do More with Less

One moldmaker makes significant advances in programming and machining productivity while reducing cutting tool costs.

-

Think Metric, Part 3

Insight from several technology suppliers—in design software, mold components, programming, machines, cutting tools and measurement equipment who have been following the metric trend—may help to make the transition a smooth one.

-

Moving Moldmaking Forward with Dynamic Toolpaths

It's not a matter of how much equipment or manpower you have. What is more important is how well you use what you've got.

-

2013 Leadtime Leader Awards: Honorable Mention Micro Mold Company, Inc.: Partnering to Push the Limits

This mold manufacturer wins the 2013 Leadtime Leader Honorable Mention title because it exceeds expectations with a team mentality—stemming from its youthful leadership working closely with skilled tradesmen—that sees customers, its sister molding company and industry associations as true partners.

-

Software Advances Push Limits of Speed and Quality

Software for moldmaking continues to evolve as sophisticated features and capabilities are introduced, enabling mold manufacturers to produce the highest quality work in the most compressed leadtimes to date.

-

No-cost CAM Upgrade Gives Moldmaker Major Productivity Boosts

The latest version of Mastercam CAM software from CNC Software, Inc. contains several new features that will greatly improve productivity, especially roughing and fine finishing.

-

Automation Advancements Streamline Mold Manufacturing

Implementing new technologies across the entire shop floor improves overall accuracy, productivity and profitability.

-

How to Lengthen Tool Life with CAM Software Moves

Long tool life is a combination of three elements: the tooling used the way it’s designed to be used; the holder to contain that tool as rigidly as possible; and how the programming software is applied

-

Afraid of Pushing Your Cutting Tools?

How advanced software and cutting tool technologies take the fear out of pushing your tools.

-

Toolpath Slashes Roughing Time

Mastercam/CNC Software, Inc. (Tolland, CT) offers OptiRough, a technique designed to remove large amounts of material quickly using dynamic milling motion.

-

Case Study / Software, Energy/Power Generation, Defense

CAM Capabilities Give Hi-Tech Mold & Tool an Edge on Engineering Resin Components

-

2011 Leadtime Leader Awards: Small Shop Honorable Mention

JM Mold South, Inc.: Constant Reinvention Results in Growth, Success.

-

2011 Leadtime Leader Awards: Large Shop Honorable Mention

MSI Mold Builders: Redefining Mold Manufacturing with Incremental Approval Approach.

-

2011 Leadtime Leader Awards: Large Shop Winner

United Tool & Mold, Inc.: Charging Forward with Unique Mold Repair Niche.

-

2011 Leadtime Leader Awards: Small Shop Winner

Mold-Tech, Inc.: Technology-Driven, Detail-Oriented Precision Injection Mold Provider.

-

Powerful Machining Software

Mastercam® X5.

-

New Dynamic Milling, Multiaxis Machining, Smart Hybrid Finishing

CNC Software announces the release of Mastercam X5.

-

Three Reasons to Maintain Your CAD/CAM

Maintain Your CAD/CAM Software, like any tool in the shop, needs maintenance.

-

The Many Dimensions of Feature-Based Machining

Simple does not mean minimal. FBM is a powerful tool that can save many different types of users’ time and money. Here’s why.

-

Avoid Chasing CNC Variability with CAM

Moldmakers who produce tooling for medical devices and many other high precision molded products have been under increasingly greater pressure to reduce the variability of tooling components manufactured on their CNC equipment. One way they attempt to do this is by carefully adjusting offsets in the CAM program to compensate for variations in their equipment’s volumetric accuracy. Sometimes this works, other times not. Either way, the toolmaker pays a heavy penalty.

-

Toolmakers Will All Have College Degrees

Anchor Glass Container Corporation’s Mold Division plans to stay competitive with a well educated workforce.

-

Software Enhances Advancing Technologies

CAD/CAM’s improved features and new capabilities—combined with the latest in technologies like high speed and five-axis machining, new cutting tools and 3-D technologies—allow moldmakers to achieve the highest quality in the shortest time.

-

Extreme Tool and Engineering, Inc.: Embracing Change

This shop—never content to rest on its laurels—combines lean initiatives and the latest in technology to be a one-stop shop for its customers and win the MoldMaking Technology 2008 Leadtime Leader Award: Small Shop.

-

How to Evaluate Your Software Reseller

Your CAD/CAM reseller plays an important role in your use of software by offering technical support, answering your questions and making sure you are productive as quickly as possible. Therefore, it’s important to consider the following nine factors when evaluating them before choosing a new CAD/CAM system.

-

Rediscovering CAM

Exploring underused CAM features that can improve moldmaking productivity and trim operating costs.

-

Tech Tool & Mold, Inc.: Strength and Flexibility

This moldmaker garners the 2007 Leadtime Leader Award: Small Shop by being flexible with its customers, going lean, competing globally and uniting with other moldmakers.

-

Molding New Moldmakers

One school—with industry’s help—is a model for our future moldmakers’ education.

-

Automation and Moldmaking: Mold Production in Action

Moldmakers are starting to change the way they think and incorporate automation into all aspects of their operation—combining a multitude of processes in a single cell for optimal productivity.

-

MSI Mold Builders: Moldmaking Measured and Defined

A combination of lean strategies coupled with niche moldmaking garners this shop the MoldMaking Technology 2006 Leadtime Leader Honorable Mention: Large Shop.

-

CAD/CAM Does Double Duty

CAD/CAM software makes molds faster and helps trim parts.

-

How CAD/CAM Is Making a Programmer’s Job Easier

Arming yourself with the appropriate information will help you select the right software to help your shop work smarter not harder.

-

Conquering CAD/CAM Challenges

Leading software manufacturers and suppliers reveal how moldmakers can maximize efficiencies using the latest CAD/CAM equipment so they can program and cut complex molds in less time than ever before.

-

Intuitive Software Yields Production-Quality Aluminum Moldmaking

This rapid prototyping shop uses its expertise with versatile and customizable CAD/CAM/CNC software to overcome the development challenges of a unique new product.

-

Technology and Skill Are Keys to Mold Shop Success

In a driven and changing mold industry, a secret weapon has helped one mold shop to excel and grow.

-

A Different View of Faster Moldmaking

Timesaving software shortcuts and a choice of materials give a rapid prototyping shop a competitive edge.

-

The Art of Design and Machining

The market is ready to explode as vendors introduce enhancements and upgrades to make the designing and machining of molds and mold components easier and more efficient.

-

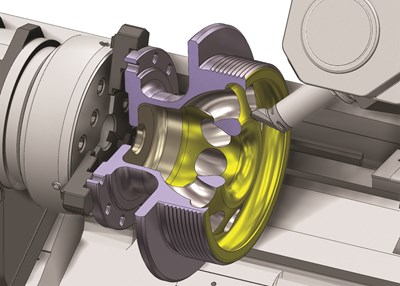

Expanding Business Opportunities With Five-Axis Software

Moving to five-axis machining may seem a daunting maneuver, but with the right software and training, a moldmaker can gain an advantage on the competition.