Diamonds in the Roughing

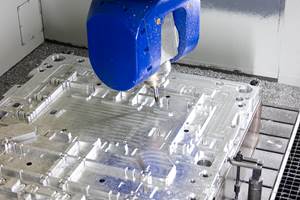

This mold manufacturer discovered significant time and cost savings in a previously unexplored feature of its CAM software.

Share

Read Next

In just six months, Accede Mold & Tool has improved roughing cycle times by as much as 50 percent while also reducing tool costs. All it took was a capability already present in the company’s CAM software.

It’s not as if programmers like Robert Fackelman weren’t aware of Dynamic Motion technology, which automatically adjusts parameters according to cutting conditions. In fact, he recalls seeing tool paths incorporating this technology during his first experiments with the Rochester, New York, shop’s Mastercam software. However, he and his coworkers were simply too busy to fully explore the capability. Suffice it to say that they didn’t know what they were missing. The team reports that beyond providing the aforementioned time and cost savings, Dynamic Motion is easier on equipment, minimizes heat in even the hardest workpiece material, and makes programming faster and easier.

An Eye-Opener

Accede Mold & Tool purchased its first seat of Mastercam from CNC Software in 2011. The rapidly growing company needed to attract additional programmers, so it chose a software product that had a high population of experienced users. Ironically, Fackelman would be the first person at Accede to use the software, despite having no prior experience with it. Nonetheless, he adapted quickly and was soon programming standard Mastercam roughing tool paths that were just as efficient as those from the shop’s other software.

Fackelman achieved this despite having only recently transitioned to programming full time after eight years as a machinist at Accede, which specializes in the design, manufacture and full qualification of stack molds, multi-shot tooling, closure molds and other complex, high-precision injection tooling. Staying competitive requires keeping up with technology, and at Accede, this task falls to more than just those who make the purchasing decisions. Having employees attend technology demos, whether in-house or at a vendor’s facility, is typically more than worth the cost of an afternoon away from the shop, says Tom Flaherty, CNC manager.

One of the most significant and recent examples was a half-day demonstration at Mastercam reseller OptiPro in early 2014. There, Accede staffers watched as a Dynamic Motion tool path roughed out steel pockets twice as fast as they would ever have thought possible. Afterwards, Flaherty and a few others immediately returned to the shop to conduct their own trials of a feature that they’d never fully explored. “The roughing speed really caught our attention,” he recalls. “It was impressive to take such big depths of cut and heavy side milling without doing any damage. It was a real eye-opener for us compared to what we were doing, pounding away at steel with insert cutters.”

Unleashed Potential

Today, Dynamic Motion is Accede’s default selection for virtually every roughing operation. The technology relies on intelligence in the software to access an extensive data set and then “decide” on the most efficient cutting motions possible for the specific part. According to the developer, the software takes into account not only the area to be machined, but also material conditions that change throughout the cut. For Accede, this translates to the estimated 50-percent reduction in roughing cycles mentioned above. Faster cycles, in turn, mean parts can move from machining to heat-treat about 25 percent faster, Fackelman says.

However, benefits extend beyond time savings. Examples include:

• Reduced cutting tool costs. On one program, Fackelman allowed for changing tools six times, the same frequency he once used with the shop’s insert cutters. When the program finished, four tools hadn’t been used.

• Smoother machining. Dynamic Motion tool paths are easier on Accede’s machines, many of which are expensive, ultra-rigid models with ceramic bearings. “There is no constant pounding as there is with an insert cutter that is continually moving in and out of the material,” Flaherty says. “The tool is constantly in the material or lifting up and out of the material in a fashion that doesn’t cause vibration to rough the spindle. The spindle load stays low.”

• Improved programming productivity. CNC programs incorporating Dynamic Motion are easy to write, Fackelman reports. The user selects feeds, speeds and chip load parameters, and the software automatically applies the chosen tool path to the designated area of the workpiece. As a result, Fackelman says his personal productivity (based on number of programs generated) has improved by about 25 percent. Such a gain has ripple effects as well. For instance, once he’s done with roughing operations, he can help program finishing operations.

• Reduced heat in hard materials. At Accede, looking up readily accessible parameters and inserting them into the program has enabled machining materials as hard as 60 HRC. Fackelman cites one memorable job as an example: “We had a lot of failures with a cinder material while using insert cutters. We were just beating up the inserts faster than we could change them. We were losing the insert edge, hitting the tool body, and then destroying the insert cutter itself. We wrote a Dynamic Motion path to do a test cut to see how it would perform and how the tool would hold up. There was no heat put into the part. There was no heat put into the tool. All the heat is transferred into the chip itself.”

• Use of a single tool. “I like that I can use the same end mill to rough and then come back to do a semi-finish to make everything look prettier before it goes to heat-treat,” Fackelman says. “It’s just a little thing, but little things add up.”

• Reliable tool paths. Short runs often have mold manufacturers continually setting up and unloading parts, leaving little time to baby-sit machining routines. Particularly in concert with Mastercam’s simulation capability, Dynamic Motion tool paths are reliable enough to push “cycle start” and walk away, Flaherty says.

• No extra investment. For Accede, realizing these benefits didn’t require any new software or equipment. All the shop had to supply was a drive to improve and a willingness to take a hard look at available technology, both outside and within its own four walls.

Related Content

True Five-Axis Machine Yields More Throughput, Greater Productivity

CDM Tool & Mfg. Co. LLC increased shop capacity thanks to a versatile high-speed/high-accuracy five-axis Fooke mill capable of cutting very large workpieces quickly and accurately with fewer setups.

Read MoreCAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

Read MoreIn "Hybrid" FIM Process, 3D Printing Complements Injection Molding

Alpine Advanced Materials used a desktop 3D printer and the freeform injection molding process to reduce prototype tooling production time and cost for its customers.

Read MoreFive-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More