A Cooperative Spirit and Uncommon Service: Baumann Tool & Die

With a philosophy of ‘being there for the life of the tool,’ Baumann Tool & Die offers molders a host of design, production and maintenance services to extend tool life.

What does Baumann Tool & Die do and what is its specialty in mold building?

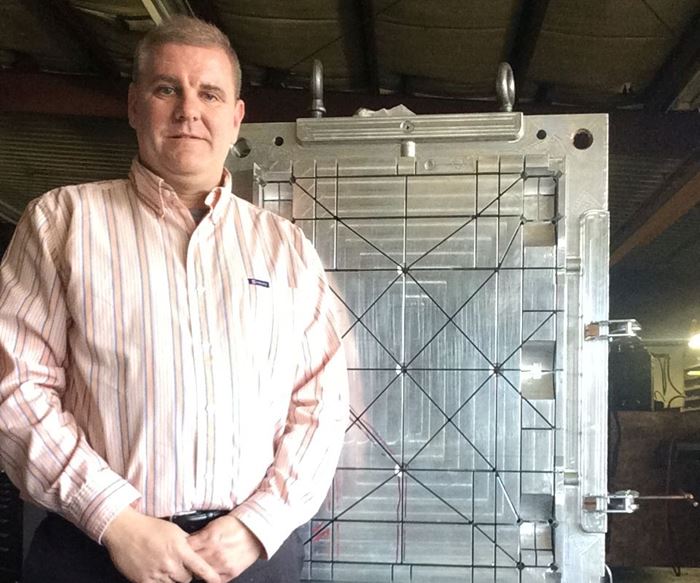

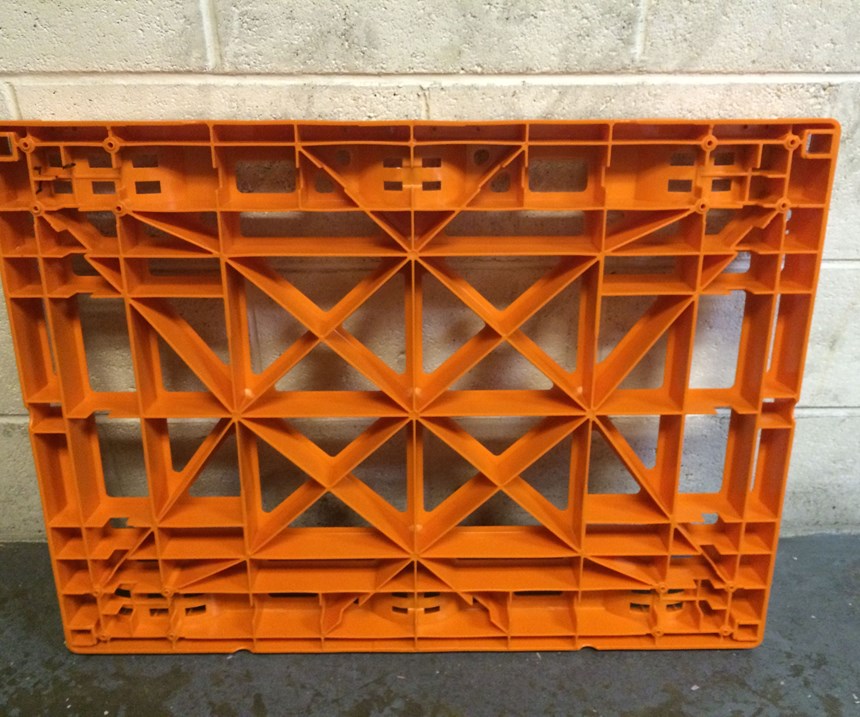

Mark Brown, CEO: We produce production molds for plastic injection, as well as prototype and production ren hob tooling for urethane foam molding. We also do tooling for compression molding and thermoforming. And we support some local automation companies by producing test fixtures, assembly line nests, bases for robots and miscellaneous tooling needs.

Our specialty is producing injection molds for returnable pallets and containers that fit on presses that are 800 tons or smaller. Many of our tools are in aluminum for lower volume production runs (in the 100,000 to 200,000-piece range), although we do work in harder tooling for larger production runs.

With our smaller aluminum tools, we’re very competitively priced with the China market. For local customers, our 6-9 week turnaround time means we can also beat the timing of overseas mold builders. If you look at all the costs, it really is cheaper to build tools here in the U.S. Most companies don’t take into account the extra engineering costs of verifying if the tool is being made correctly.

We have a state-of-the art, 13,000-square foot [1,208-square meter] manufacturing center that was specifically designed for lean manufacturing to increase throughput and shorten lead times. We believe that our manufacturing partners expect a high level of service, efficiency, craftsmanship and quality. Our goal is to always exceed our customers’ expectations.

We have mold designers with over 30 years’ experience, so we’re uniquely qualified to design a customer’s first prototype mold or fixture, and later produce a production mold to mass-produce that piece — all at a competitive price with optimized precision. In our shop we have five CNC milling machines, four Bridgeport milling centers with digital readouts, one EDM machine, three grinders, four lathes, two radial drill presses, two saws, two welders and a 150-ton spotting press. To support our design work, we use MasterCam, Solid Works and Autodesk’s Fusion 360 software.

baumann tool & die

Your company has a reputation for being very collaborative and working closely with other tool makers. Can you tell us about that?

Brown: There are four local toolmakers who support each other. We each have different customers and slightly different capabilities and equipment, so we don’t really overlap or compete. We all met at local AMBA (American Mold Builders Association) meetings and started comparing notes. We asked each other why we should each buy a machine that we only used 30% of the time when someone else had the same piece of equipment that wasn’t being used that much. It makes more sense to share the work and time on the equipment so we all stay competitive.

For example, in my shop, I have a number of smaller CNC machines, whereas another mold builder has CNC machines with bigger tables. If one of us gets a big job, we share the machining so both the big pieces and the small ones all get done at the same time. That way the job is completed faster. Yet another mold builder has newer EDMs than we have, so we buy time on their machine because they can do the work cheaper than my shop can. We’re all very respectful of each other, and we all help each other out. It’s the right thing to do.

Another thing you offer is what you call molding services. Are you actually molding parts?

Brown: No, we’re not molding parts and competing against our molder customers. Rather, if a company comes to us and wants to know who they should use to produce a particular job, we have a group of molders we regularly work with and whose capabilities we understand. We’ll make a recommendation based on who we feel would be the best fit for the job at hand. So, as part of our services, we hook up molders and customers who need those molding services.

You also repair, maintain and store molds — regardless of who originally built the tool. What does that entail?

Brown: Because our skilled toolmakers have been building and repairing plastic injection molds for nearly three decades, they’ve become experts at fixing and maintaining molds. Regardless of who built the tool, we offer services to properly maintain, repair and store that mold. We can test, clean, oil, and inspect injection molds before every production run to ensure they perform as designed. Our customer service is top-notch, and we do regular follow up with customers to help them ensure their molds keep running well now and into the future. This helps extend the working life of a mold and greatly increases the quality of parts that tool can produce.

For example, with one of our customers using an aluminum tool, every 100,000 shots that tool produces, we come in and pick up the mold, bring it back to our shop, clean it up and re-polish it, then send it back to keep the mold running well. By doing regular maintenance when it’s convenient for the molder, we keep them up and running and lessen the chance they’ll have unscheduled downtime caused by a major problem with the tool. Unscheduled downtime is never convenient. Also, customers will occasionally call us and say they have a mold that’s flashing and can we come fix it?

In addition to maintenance, we also store tools for a small fee and pull them out and deliver them when the molder needs them. We have some local customers who only use a tool a couple of times of the year or maybe even only once every couple of years. We have a big facility, so we have plenty of room to keep tools.

As we like to say about tools we build, “We like to be there for the life of the tool.”

What do you wish U.S. customers knew about the current pool of U.S. toolmakers?

Brown: There are people out there saying that we don’t have enough capacity to make molds for automotive and other industries in the U.S. anymore. However, those people aren’t coming to the actual mold builders and asking us to quote things. It’s not that we can’t make these tools, it’s that they don’t want to pay what we’re charging. Because the costs to purchase, set up and maintain a mold often are spread across a number of different departments in larger companies, it can look like it’s cheaper to purchase a tool offshore and then bring it here to get it working. However, if all the costs were considered together, it would be clear that that’s not often the case.

Related Content

Growth Requires Mold Builder/Molder to Shift Tooling Focus to Maintenance, Repair and Replacement

The results of aligning awareness and acceptance across departments to balance new tooling and quick response needs.

Read MoreIndiana Mold Builder Decatur Mold Offers a History of Grit and a Future of Innovation

Decatur Mold Tool and Engineering Inc. serves as a tooling tour guide, helping busy tooling managers reduce uncertainty, lighten workload.

Read MoreNorth Carolina Mold Builder Works With Purpose and Partnership

Adapting and innovating amidst a change in ownership, doubling sales and maintaining the workforce reflects team resilience and expertise.

Read MoreNextGen Mold Technologies is Sticking to the Plan

I caught up with Dennis Goggin, president of NextGen Mold Technologies, to learn how much has changed for this startup mold builder since we last connected.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)