A Dynamic Approach to Prototype Tooling

Software that adapts to the demands of varying cutting conditions helps this moldmaker adapt to the demands of a varying workload.

Attracting more business is virtually never a bad thing, but it can also increase time-to-market pressure—pressure that can be particularly intense when no two jobs are alike. That’s certainly been the case for Dynamic Plastics, a prototype moldmaking operation that “sees a little bit of everything,” says Tom Prebelich, tooling supervisor. “The only constant is that all of our customers continually prod us to deliver things quicker.”

The Chesterfield Township, Michigan, shop has survived in large part by adopting technologies and processes that improve efficiency without requiring additional labor, Prebelich says. Among the most recent and significant examples was the integration of Dynamic Motion technology, a capability of Mastercam CAD/CAM software from CNC Software. By predicting upcoming cutting conditions and adjusting parameters accordingly without any input, Dynamic Motion has saved time not only for programmers, but also on the shop floor through more efficient tool paths. Less risk of breakage has reduced the shop’s cutting tool costs as well.

Built-in Flexibility

“Dynamic” is a fitting term for technology that adjusts to cutting conditions on the fly. Long before adopting this software capability, however, Dynamic Plastics had to prove that it, too, was aptly named. Indeed, Prebelich says the company owes much of its success to a flexible manufacturing philosophy that has been in place for more than a decade.

At the outset of a new project, the company’s 15 shopfloor employees work together to determine work scheduling and equipment allocation. From there, the job is assigned to a single employee who is responsible for keeping tabs on material delivery and ensuring all components arrive in time for final assembly, although manufacturing tasks are often shared. Each employee plays a dual role as both a programmer and machinist. Rather than being confined to a particular machine, they stand ready to run whatever equipment the job requires.

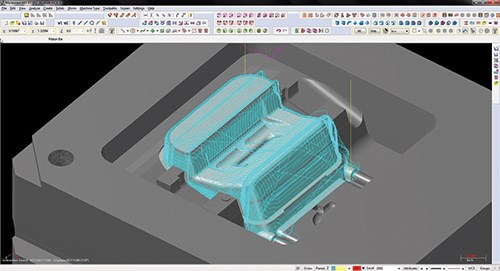

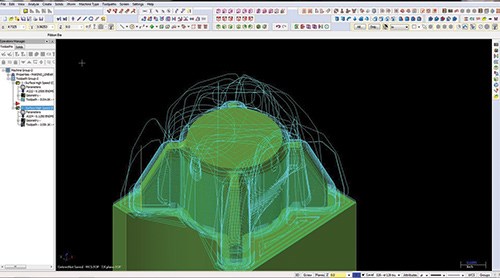

In keeping with this flexible approach, the company has a number of “floating” licenses for Mastercam that can be accessed at any workstation through one of 15 desktop icons. Each icon corresponds to a software configuration matching the work preferences of an individual employee. Beyond that, the software’s evolving capabilities have played a major role in facilitating flexibility for the past 10 years, Prebelich says, starting with a major transition from wireframe programming to 3D solids and a CAD-style user interface. Further improvements include the ability to program in any sequence to enhance freeform workflow; new tool paths, many of which can be applied straight from templates; the use of a work coordinate system (WCS) to switch rapidly among tool orientations; change recognition, which ensures changes to the model don’t compromise CAM work in progress; and simulation capability.

The Next Breakthrough

Based on the extension of Mastercam’s underlying CAD engine, these capabilities have been major assets for a company that’s continually asked to take on increasingly complex and time-sensitive applications, Prebelich says. However, by 2010, it had become obvious that modern CNC machines had advanced to the point that CAM software couldn’t make use of all the available speed and precision, he adds. Even with the latest machine tools, the shop had added a third shift because it simply couldn’t produce prototype mold components fast enough with only two.

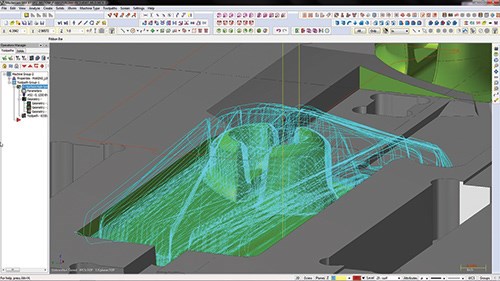

Part of the problem was the need to adjust feeds, speeds and tool approaches to avoid chatter and tool breakage at points in the tool path where material conditions tend to change, including entry points, exit points, corners and curves. Although programmers could adjust such parameters manually, they often found it less time-consuming to simply skip all that additional programming and run at slower feeds and speeds.

This changed in 2011, when the company first implemented Dynamic Motion technology. According to the developer, the system employs a massive, intelligent algorithm that automatically and progressively analyzes the material condition ahead of the tool. It then adjusts entries, exits, feeds, speeds and tool approaches accordingly to optimize the pace of material removal and to reduce tool wear. “I didn’t know what I was going to get,” Prebelich says about his first attempts to write a program employing Dynamic Motion technology. “But after I wrote a few tool paths, I was pretty keen on getting them out onto the shop floor.”

Smooth Transitions

One reason Prebelich was so enthused is that he could tell the system would not only be easy to implement, but also save significant time for programmers. “The new tool paths with Dynamic Motion technology were similar to the ones we were already using, but required less programming,” he explains. “Today, it takes as little as a half hour to write programs for all the surface work on a typical mold. The same work would have taken us twice as long a few years ago.”

Results were even more impressive once Dynamic Motion tool paths arrived at the machines, he says. Tools cut at higher feed rates and with greater (sometimes full) engagement, despite the use of smaller stepovers to decrease lateral forces and tool wear. These advantages stem from the fact that Dynamic Motion maintains the chip load within a consistently narrow range. As a result, machines can operate at higher feeds and speeds. “We now run our feed rate to keep chip load constant at 20,000 rpm,” Prebelich says. “If we had higher-speed spindles, we could feed even faster.”

Smoother cutting not only improves cycle time, but also limits the risk of tool breakage. The shop’s carbide costs have dropped as a result. In addition, operators can confidently use tools as small as 0.03 inch in diameter to achieve finer surface finishes with fewer operations. Smoother surfaces, in turn, limit the need for secondary operations to avoid mold flashing. Prebelich adds that the use of air/oil mist coolant on all machines complements Dynamic Motion by improving chip evacuation, keeping tools cool and lubricating without thermal shock.

Today, toolpaths plotted with Dynamic Motion technology are the manufacturing team’s first choice for most applications, Prebelich says. After all, programming time savings, machining efficiency and reduced consumable costs have all played a role in the company’s recent growth. In the past five years alone, Dynamic Plastics has eliminated the third shift, doubled its number of CNC spindles, completed a 12,000-square-foot facility addition to accommodate new equipment, and further reduced lead times. All the while, it’s maintained competitive pricing, and the staff of programmer/machinists has grown only 15 percent, Prebelich says.

Related Content

Integrated CAD/CAM Streamlines Electrode Manufacture, Improves Quality

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Read MoreCAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

Read MoreLarge Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read MoreLaser Welder Yields Fast, Precise Mold Repair

Intralox's integration of the Alpha Laser ALFlak has significantly improved their tool room efficiency when it comes to difficult welds and urgent repairs.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)