Intuitive Software Yields Production-Quality Aluminum Moldmaking

This rapid prototyping shop uses its expertise with versatile and customizable CAD/CAM/CNC software to overcome the development challenges of a unique new product.

| Speed is everything for Dynamic Plastics, Inc. (Chesterfield Township, MI). Its market niche demands it and one manufacturer among many benefited from it in the development stage of its unique and innovative product: the Segway Human Transporter (HT).

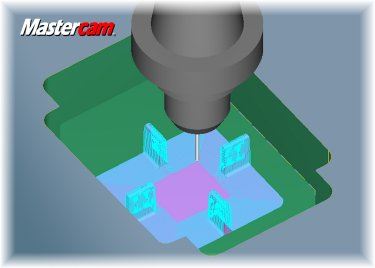

Dynamic Plastics, Inc. (DP) specializes in rapid manufacturing of prototype plastic injection molds for customers who need small but high-quality parts runs-which DP also provides from its 25,000-square-foot facility. "What sets us apart from our competition is our triple-duty moldmakers," says DP tooling manager Tom Prebelich. "For most jobs, they not only create toolpaths and do the machining; they do their own design work. Our choice of what we believe is the CAD/CAM/CNC program with the most user-friendly interface allows our crew the latitude to apply a wide variety of their skills to get the whole process done quickly and accurately." DP's skilled designer/programmer/machinists, materials selection experience and shop floor scheduling flexibility are key contributors to the shop's reliability. With design and toolpathing driven by Mastercam software (from CNC Software, Tolland CT), DP is highly competitive in many time-critical prototyping scenarios. Accurate-the-first-time machining in high-quality aluminum set them up for production right from the prototype stage.

The Software SecretJ. R. Hoell, mechanical engineer for Segway LLC, outsourced to DP earlier in his career and, aware of DP's expertise in applying Mastercam to moldmaking, asked Connell and his partner, Joe Doss, to bid on the moldmaking and limited production of several parts during the development of the Segway HT. For Segway, this added up to production-quality parts from QC7 aluminum mold tooling in product-introduction quantities-minus the added startup expense of steel tooling. While many shops find it difficult to work with aluminum stock, Mastercam's materials library gave DP technicians the criteria for optimum feed and speed rates. Additional functions like MoldPlus for Mastercam radically reduces DP's mold or tool design cycle. Jobs that once took long tedious hours can now be done in minutes; MoldPlus automates repetitive or complex design tasks, creating parting lines and automating the separation of core-and-cavity geometry.A must for rapid prototyping shops and a plus for most other shops, Mastercam's toolpath associativity automatically updates those toolpaths linked with changes in geometry. As soon as the changes are made, the technician clicks on the Regenerate command. Within seconds, the updated toolpath is ready to run. Mastercam's HSM parameters boost DP's rapid prototype turnaround by speeding the tool through linear, shallower cutting. The program intuitively slows for corners and details, and then resumes feed speed on the next simpler part of the toolpath.

The ProjectThe Segway Human Transporter took on a life of its own when key outside suppliers-namely DP-were brought on board for the development process. Doss was DP's manager for Segway projects and worked out production details and time-saving mold design alternatives.

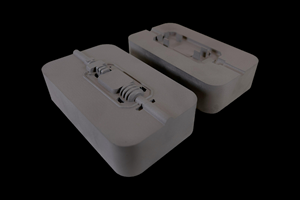

During Segway's design conferences Doss suggested an inter-projecting core and cavity design for a shaft locking assembly. It included four male cores, which telescoped into the mating cavity parts. When closed, the mold parts formed O-ring seats at two heights around the inside surface of the ferrule. The nut is screwed over the ferrule, completing the height adjust collar inside which the rings provide the grip to hold the Segway's control shaft position setting securely. Doss also collaborated in the development of bypassing cores, which left four vertical gaps in the ferrule wall, freeing the four remaining solid sections-these end up inside the nut after fabrication-to flex inward toward the control shaft as the assembly is tightened. DP also worked with Segway people to develop the method of overmolding the soft plastic sheath that serves as a non-slip grip when users tighten the height adjust collar. Doss felt that Segway's team was particularly open to discuss ideas and listen to suggestions, "We tried to use our experience with materials and Mastercam to help make the projects more toolable" - Doss' word for DP's ability to simplify mold design toward more straightforward, time-saving toolpathing; and, for example, to use an intermediate-finish pass for faster stock removal, leaving the finish pass with little stock-to-remove. That allowed them to use Mastercam's leftover feature to go back in and finish the detailed sections at higher speeds with a .060-inch flat or ball mill to improve production speed and quality.

Versatility Is a MustThe speed and direction of the Segway HT are controlled by the angle and direction in which the rider leans; function controls and indicators are in the handlebar. One handgrip steers the HT in a 0x turning radius and the control shaft telescopes to adjust to individual riders' comfort. DP made the prototype/production molds for the control shaft's two-part height adjust collar-a two-piece ferrule with overmolding-and as the project progressed, battery cases, trim parts and a three-part, multimaterial wedge for the control shaft base clamping mechanism. Along the way, DP machined main housing and gearbox casing prototypes from the same QC7 aluminum used for the molds. The extra-hard QC7 aluminum is the foundation of DP's turnaround time and production quality. Using Mastercam optimized feed and speed rates; DP machined the QC7 so no material gummed up the tooling or stock, and finished molds were capable of running upwards of 50,000 parts with steel-like precision. Cutting TimeTooling foreman Tom Prebelich ran the program through the shop. "Our technicians can take virtually any kind of file into Mastercam," Prebelich observes, "and move the job right along. In a real rush situation, we'll separate the customer's model, design the cavity mold, and hand that off to another operator so machining begins on the job even before the whole mold is designed." With 13 designer/programmer/machinists in-house, the machines keep on cutting and the parts just keep on coming!Four projections in the mold cavity that telescope into the mating part allow for a rib at both the top and bottom surface to capture washers inside the piece at two levels. When the threaded female ferrule is drawn over the resulting four-part cylindrical cone of the male, the washers are compressed, creating ample friction to set the handlebar height firmly. Initial designs called for solid rings of plastic at different levels. The DP team worked through a suggestion with Segway to interrupt the rings of plastic without having integral mold action or moveable pieces. Pete Anders, DP's molding foreman, worked with Doss and Prebelich to establish the molding process parameters and parts sequences. This simplified tooling, further reducing cost by saving time in designing the action and machining it.

Getting Down to the PartsSegway sent Pro/ENGINEER part files, which DP technicians brought into Mastercam for any revisions and for toolpathing. Loose, hand-inserted mold pieces formed the threads of the male ferrule. Prebelich says, "We take the two pieces together and drop them into the larger, ejector side of the tool. It's closed, the plastic is injected and, when the tool opens, the mold pieces are ejected with part." They must be hand separated during the limited-production startup period, but the time spent on handling as part of the production process was surprisingly less and the cutting time far faster than cutting steel for prototype tooling. A softer, hand-grip part was overmolded on the female ferrule after it was molded with threads by replacing the two threaded hand-loads with two for the second shot. DP has currently been performing 10,000-part runs for Segway using hand-inserted mold parts, but now that production is ramping up, the tooling will be augmented with slides, pushing the pieces together into the mold as it closes and changing them for the second shot. "The production time constraints and our own quality control don't leave room for dealing with flash either," reports Prebelich. "The mold parts must fit right the first time. Using MoldPlus (an add-in for Mastercam), we copy the run-off and parting line surfaces for the cavity mold into the core mold layer for that perfect fit. In the seven years we have used Mastercam's MoldPlus it has given us a time savings of up to 70 percent on the most complex jobs."

Cutting in Real Time"We like to do an intermediate semi-rough surface toolpath, stepping down to a 0.25-inch bullnose mill with a 0.020-inch radius," Prebelich says, "to get it closer to the finish dimensions, but still perform a fairly aggressive cut. Since our software remembers what it has cut, I was able to use the leftover feature with a much smaller cutter-a 0.060-inch flat or ball mill, depending on the geometry-to clean just the stock left from corners and details missed by the larger cutters. Finally, surface finish contour and, in some places, surface finish parallel toolpathing gave us an extremely clean mold surface finish." Rather than adding machining time, DP's three-step progression of toolpaths allowed faster results. Running appropriate feed and speed rates for each successive cutter in the progression kept feed speeds high without pushing the tools to their respective limits. With this rough to semi-rough to finish combination, larger cutters give greater speed while leftover, with its quick cleanup, completed the details with time to spare.

Accuracy AchievedReports on the Segway HT hail the machine for its superb functionality, elegant design and high quality. Doss claims, "Mastercam gave us the accuracy needed to produce parts at a level of quality in keeping with Segway's engineering idealism."

|

Related Content

2024 Moldmaking Insights: A Year in Review Part 1

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

Read MoreAdvancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

Read MoreLarge Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read MoreMold Builder Uses Metal 3D Printing to Bridge Medical Product Development to Production

Westminster Tool uses metal additive manufacturing for medical device OEM, taking lessons learned from R&D in the prototype mold phase to full-scale production molding in a fraction of the time.

Read MoreRead Next

Cutting Delivery Time 50 Percent With the Right CAD/CAM Package

With the appropriate CAD/CAM software behind it, one mold shop plans to further reduce its mold tooling turnaround time and remain a supplier of choice for its customers.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More