New Dynamic Milling, Multiaxis Machining, Smart Hybrid Finishing

CNC Software announces the release of Mastercam X5.

Mastercam X5 introduces significant new capabilities, including new dynamic milling techniques, multiaxis machining, Smart Hybrid Finishing, and much more.

New Dynamic Milling Techniques

Dynamic milling constantly adjusts the toolpath to ensure the most efficient cut possible and allows use of the entire tool flute length, often eliminating the need for multiple depth cuts. New dynamic milling techniques include Dynamic Rest Mill and Dynamic Contour. Dynamic Rest Mill behaves in a manner similar to the current toolpath, only it uses dynamic milling motion instead of core mill or area mill motion for the rest operations. Dynamic Contour uses an intelligent, efficient high speed contouring strategy to remove material along walls. It supports multi-passes and can optionally include finishing passes.

Much easier multiaxis machining

Mastercam’s multiaxis suite has new machining techniques and a new, easy, workflow-oriented interface. Mastercam lets you choose the basic type of work you’re doing using clear illustrations, and then gives you a clear, step-by-step process for defining how you’ll cut the part. Mastercam’s multiaxis machining also includes a new highly specialized interface for smooth, gouge-free engine head porting.

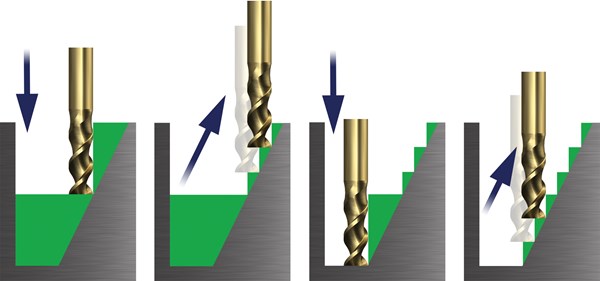

Fast, aggressive, intelligent roughing

Mastercam’s new 3D surface high speed OptiRough toolpath is a new technique designed to remove large amounts of material quickly using its successful dynamic milling motion. Large, aggressive cuts are followed by fast, smaller up-cuts, safely delivering a fully roughed part faster than ever.

Smart Hybrid Finishing

Hybrid finishing intelligently blends two efficient cutting techniques in a single toolpath. This new toolpath evaluates the model shape and smoothly switches between Constant Z cutting and Constant Scallop machining. The result is a dramatically finer finish with less work.

Related Content

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.