March MMT Digital Edition Available

From a strategy for better mold finishes and advanced thermal control to avoiding spindle crashes and automated RFID technology, this month's issue has a lot to offer. Check out our digital edition.

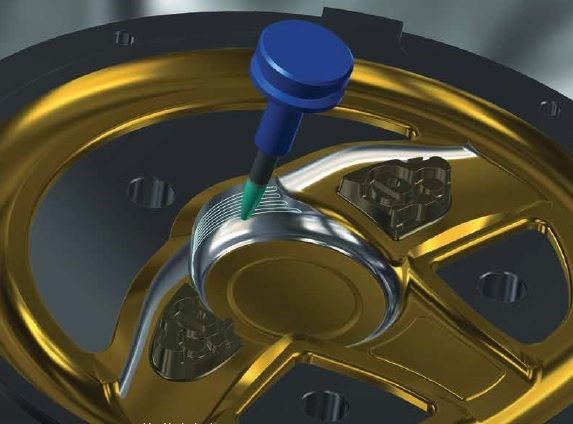

March's cover from CNC Software/Mastercam shows a steering wheel mold. Its manufacturer benefitted from new circle-segment tools and sophisticated, dynamic-finishing CAM tool paths. Circle-segment cutting tools are designed to allow a small -diameter tool to have a large effective cutting radius. This design reduces the number of finish passes and the depth of the cusps in the material for a substantially better surface finish while achieving shorter cycle times. See related story on page 12 of our digital edition.

Here are five great tips from this month's issue:

1 In an advanced finishing strategy, the circle-segment tools and CAM software need to work together to coordinate tool definitions and toolpath behaviors, particularly in 3+2 and simultaneous five-axis machining modes.

2 The key to a new rapid heat/cool technology is its unique adaptive thermal control, which allows users to separate the mold face into multiple thermal zones coupled together using complex profiles and logical arguments.

3 Magnet-based collision systems have a 5-millisecond lag time, and the magnets provide a degree of flexibility that protects the spindle and other machine parts in the time it takes the machine to stop.

4 Job management software and RFID chips ease the prioritization of workpieces as they move through automation cells by simply assigning them each a priority number between -99 and +99.

5 Standardization is the basis for automation in most German mold shops, which includes the standardization and modularization of products and processes, and the industrialization of production.